Hydraulic oil tank with built-in leather bag and rotatable position

A technology of rotating position and hydraulic oil tank, applied in the direction of oil supply tank device, mechanical equipment, etc., can solve the problems of hydraulic oil pollution, increased gas content, not conducive to the precise control of the hydraulic system, etc. achieve the effect of isolation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that the orientation terms such as left, middle, right, up, and down in the examples of the present invention are only relative concepts or refer to the normal use state of the product, and should not be considered as restrictive .

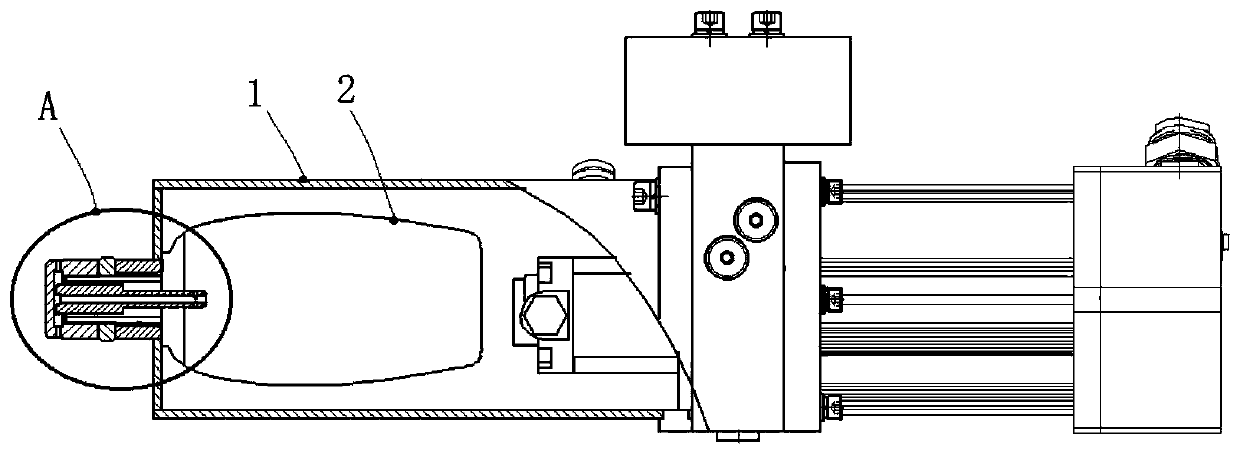

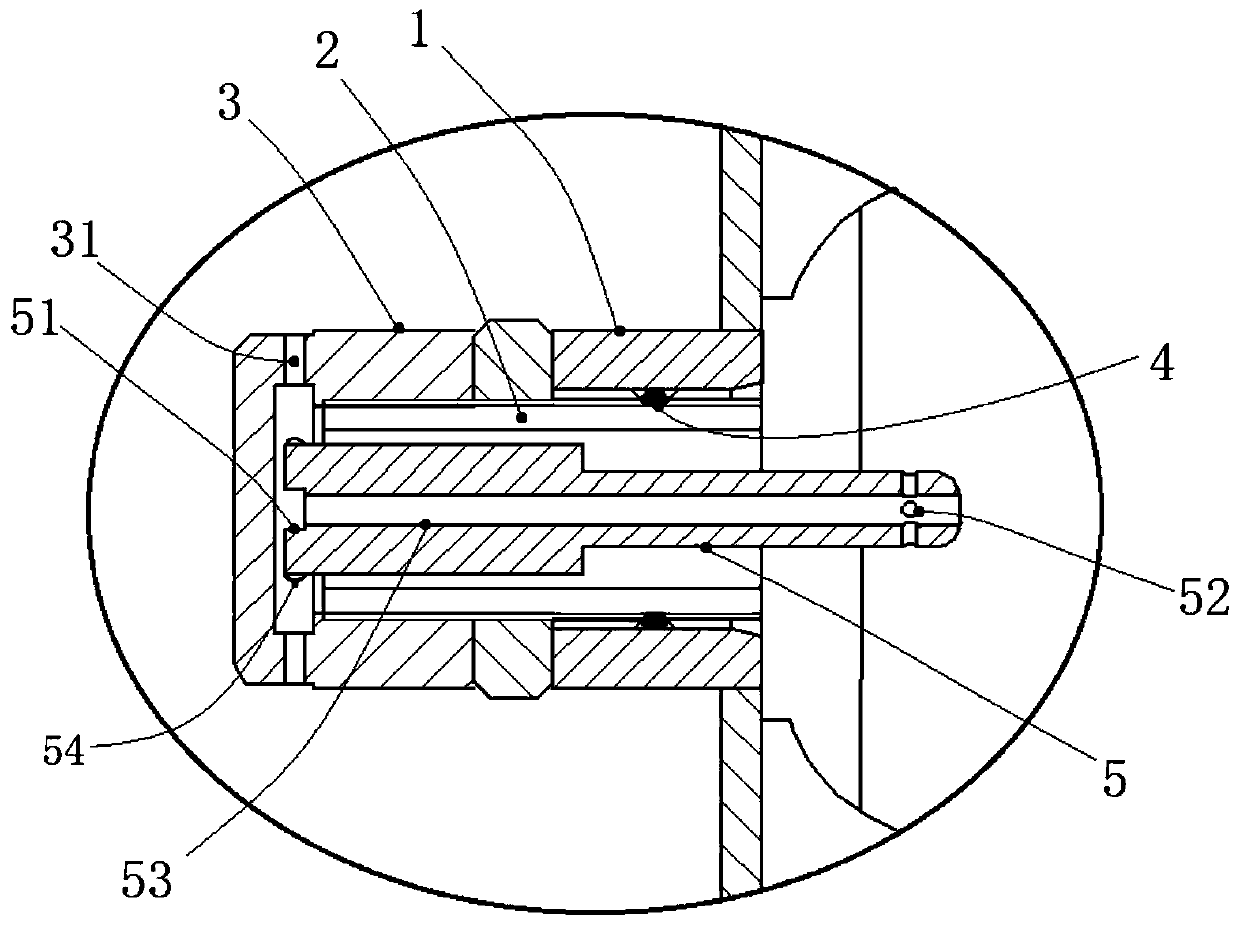

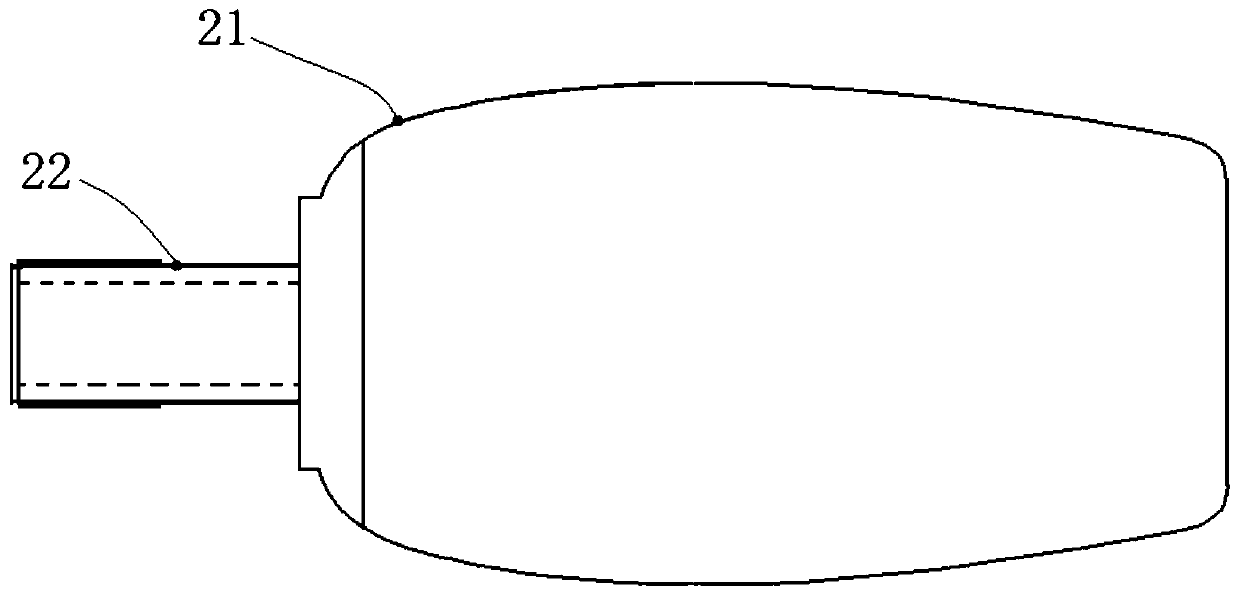

[0023] A hydraulic tank with a built-in bladder and a swivel position, such as figure 1 with figure 2 As shown, including the fuel tank 1, the working pressure of the fuel tank 1 is within 0~2Mpa, the working pressure of the hydraulic system is less than 21Mpa, and an air bag 2 is fixed in the fuel tank 1, and a first vent hole is opened on the air bag 2, A second vent hole is opened on the fuel tank 1, the first vent hole communicates with the second vent hole, and a vent rod 5 is fixed in the second vent hole, and the inner end of the vent rod 5 Located in the air bag 2, air holes 52 are distributed on the inner e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com