A double-spoke plate welded pulley

A double-spoke plate, pulley technology, applied in the direction of gear lubrication/cooling, belt/chain/gear, hoisting device, etc., can solve the problems of affecting the smoothness, the pulley and the rope are easy to rust, and the lubrication cannot be carried out in time. The effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

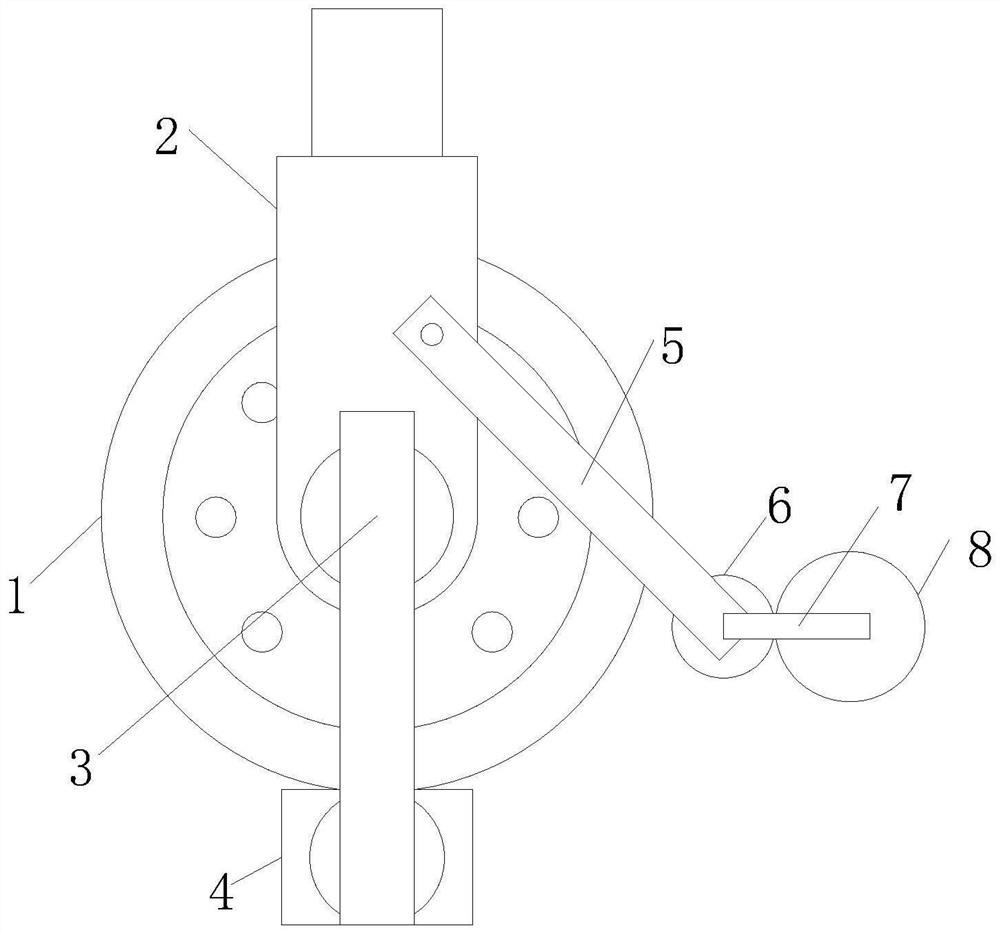

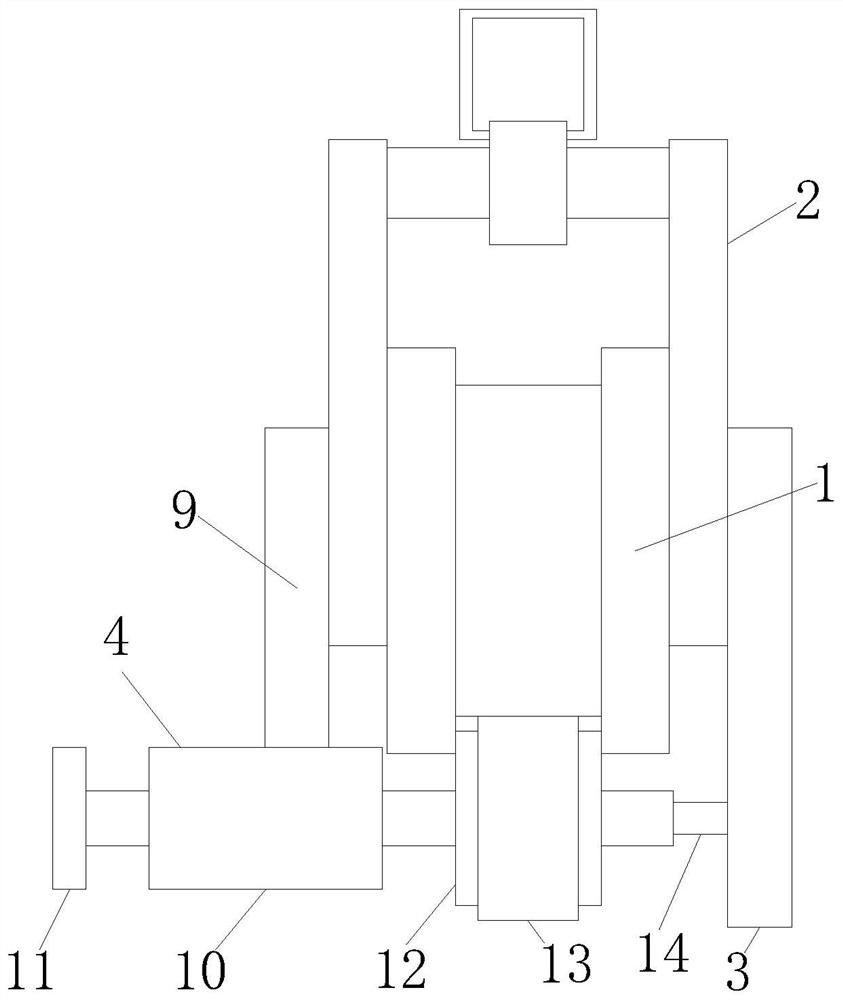

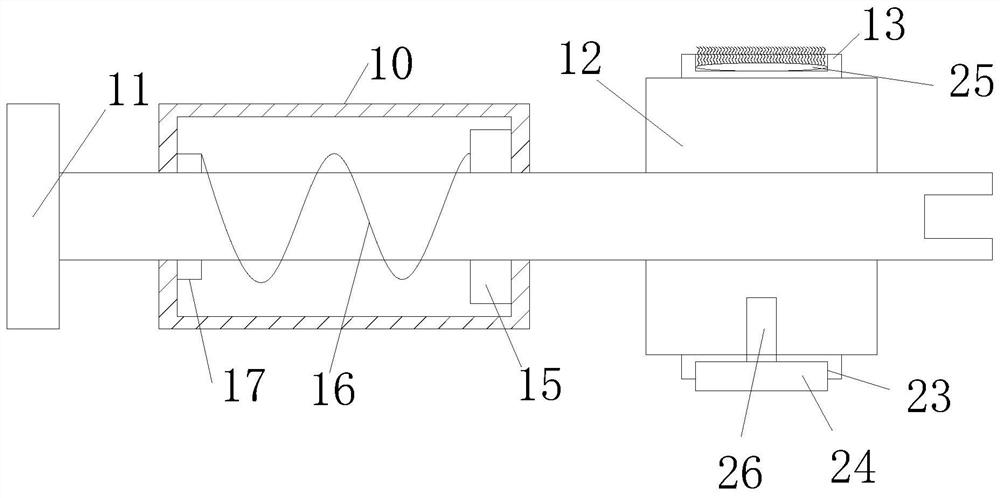

[0023] As an embodiment of the present invention, the front surface and the rear surface of the hook plate 2 are respectively provided with a third fixing plate 5, and the third fixing plate 5 is in an inclined state, and the third fixing plate 5 is located at the top of the tilt. The surface of the hook plate 2 is in the upper side position of the first fixing plate 3 and the second fixing plate 9, respectively; two of the third fixing plate 5 is provided with a stable column 18 between the opposite surfaces of the bottom end ends, the solid The second drum 6 is provided on the outer side of the column 18, and the surface of the third fixing plate 5 is provided with a connecting post 7 in the horizontal direction, and two of the connecting posts 7 are provided with a stable bar 19. The outer tube 8 is provided in the outer side of the stable rod 19; the intermediate position of the surface of the second sleeve 6 is opened, and the intermediate position of the surface of the third...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com