Anti-floating structure of pipeline and construction method of pipeline

A pipeline and tube-saving technology, which is applied in the construction field of anti-floating structures and pipelines, can solve the problems of waste, large materials, time-consuming and labor-intensive handling of sand bags, etc., and achieve the effect of saving construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in further detail below in conjunction with the accompanying drawings.

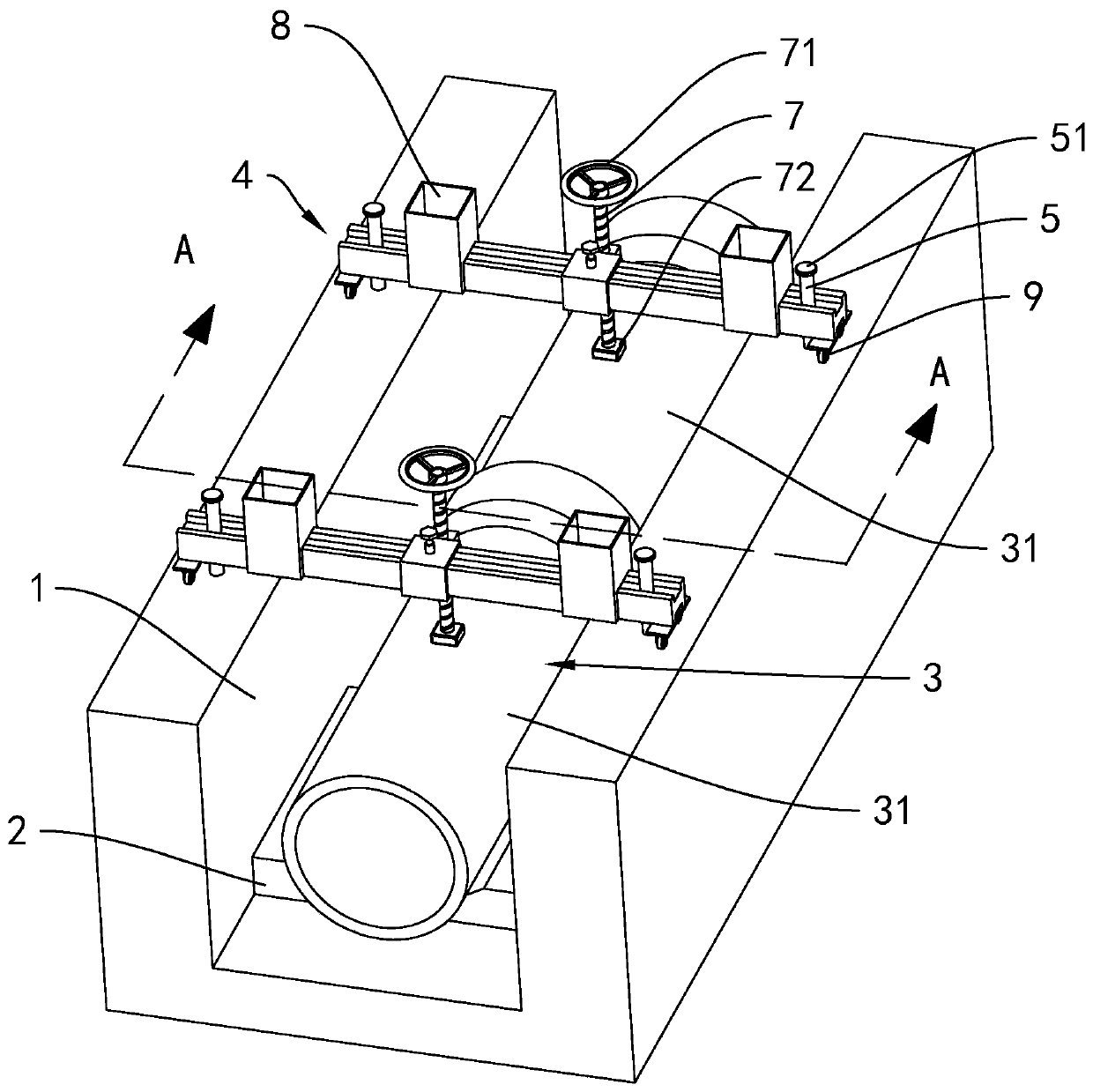

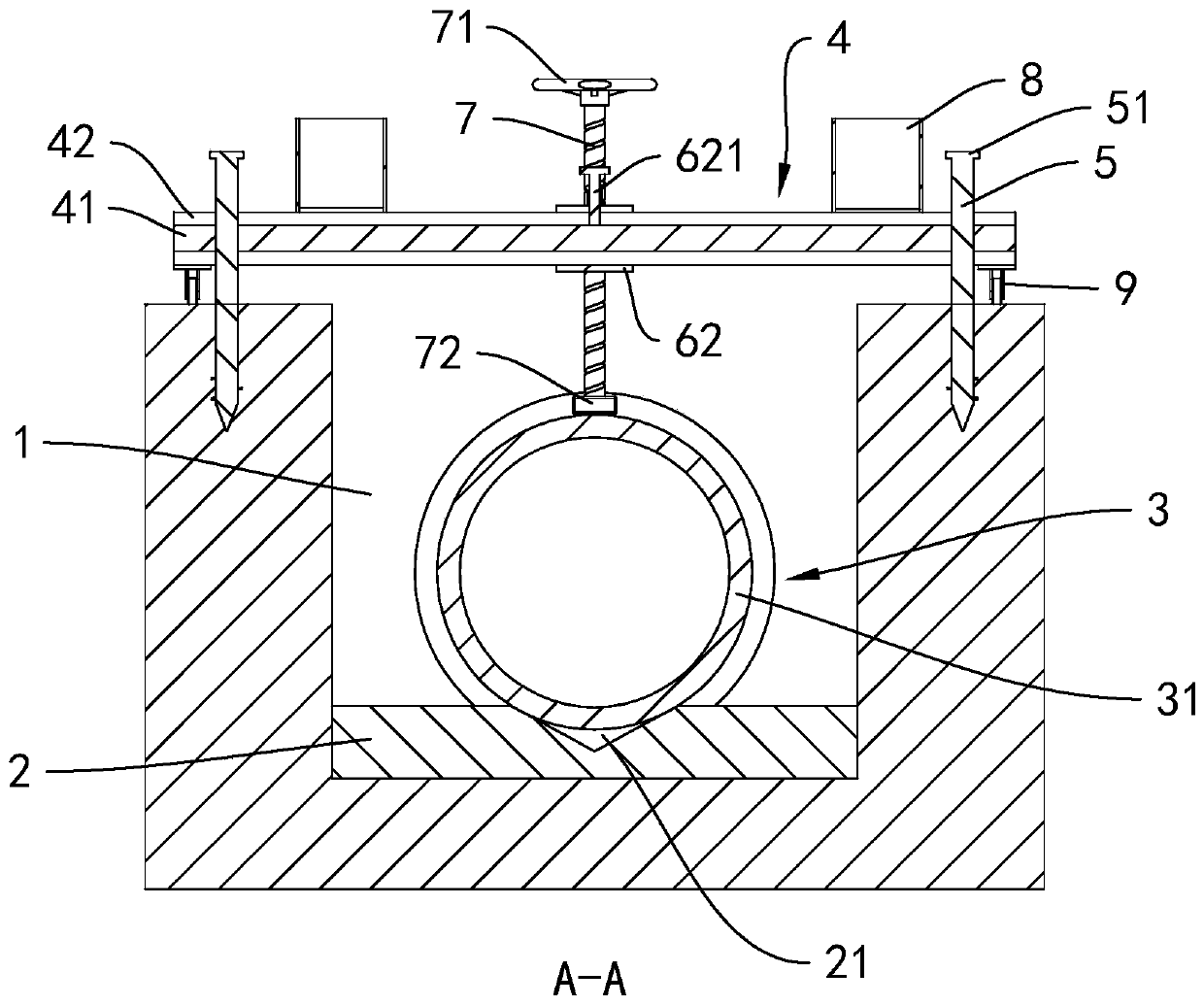

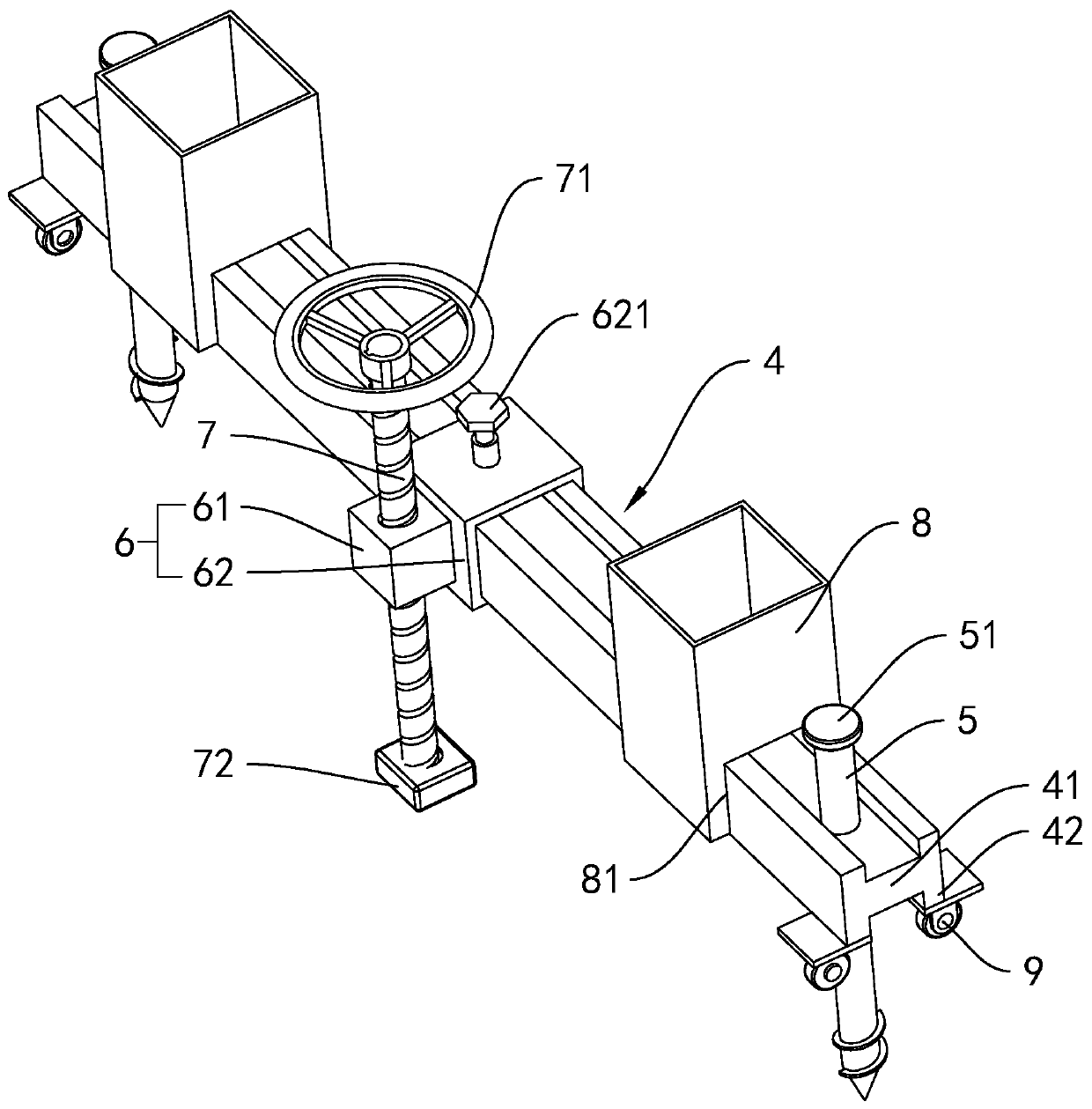

[0041] refer to figure 1 , figure 2 , is an anti-floating structure for pipelines disclosed in the present invention, which includes a pipeline installation ditch 1 on the ground, and a number of concrete pads are sequentially laid on the bottom surface of the pipeline installation ditch 1 along the length direction of the pipeline installation ditch 1 The top surfaces of the slab 2 and the concrete pad 2 are all located on the same horizontal plane.

[0042] A prefabricated pipeline 3 is arranged inside the pipeline installation ditch 1 , and the prefabricated pipeline 3 is laid on the top surface of the concrete pad 2 . The prefabricated pipeline 3 is formed by connecting several pipe joints 31 end to end. The quantity of the prefabricated pipes 3 corresponds to the quantity of the concrete backing plates 2 and is arranged one by one relative to each ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com