Device for plate machining

A plate processing and sliding plate technology, applied in the field of material processing, can solve problems such as excessive movement and insufficient movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below by means of specific embodiments:

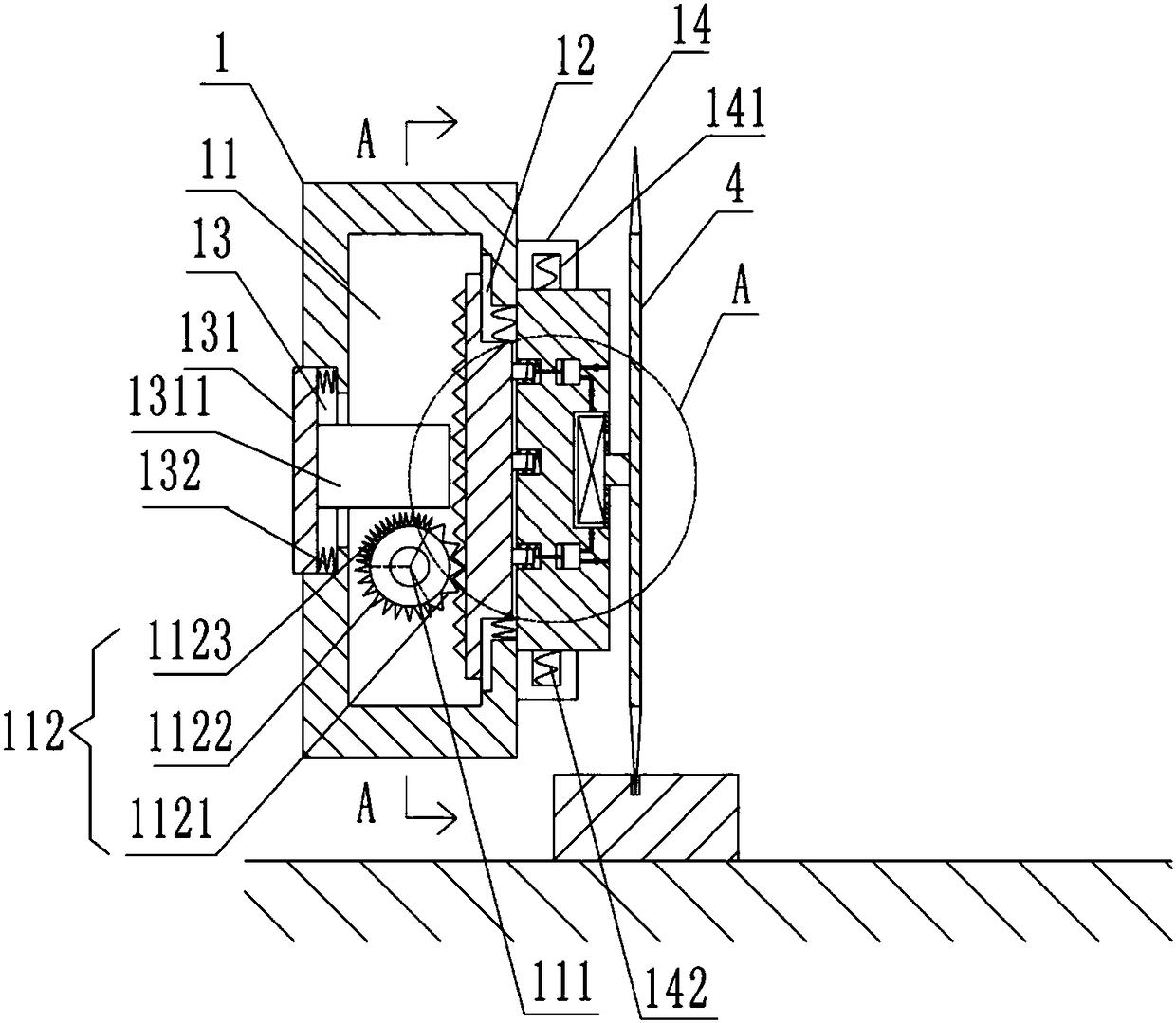

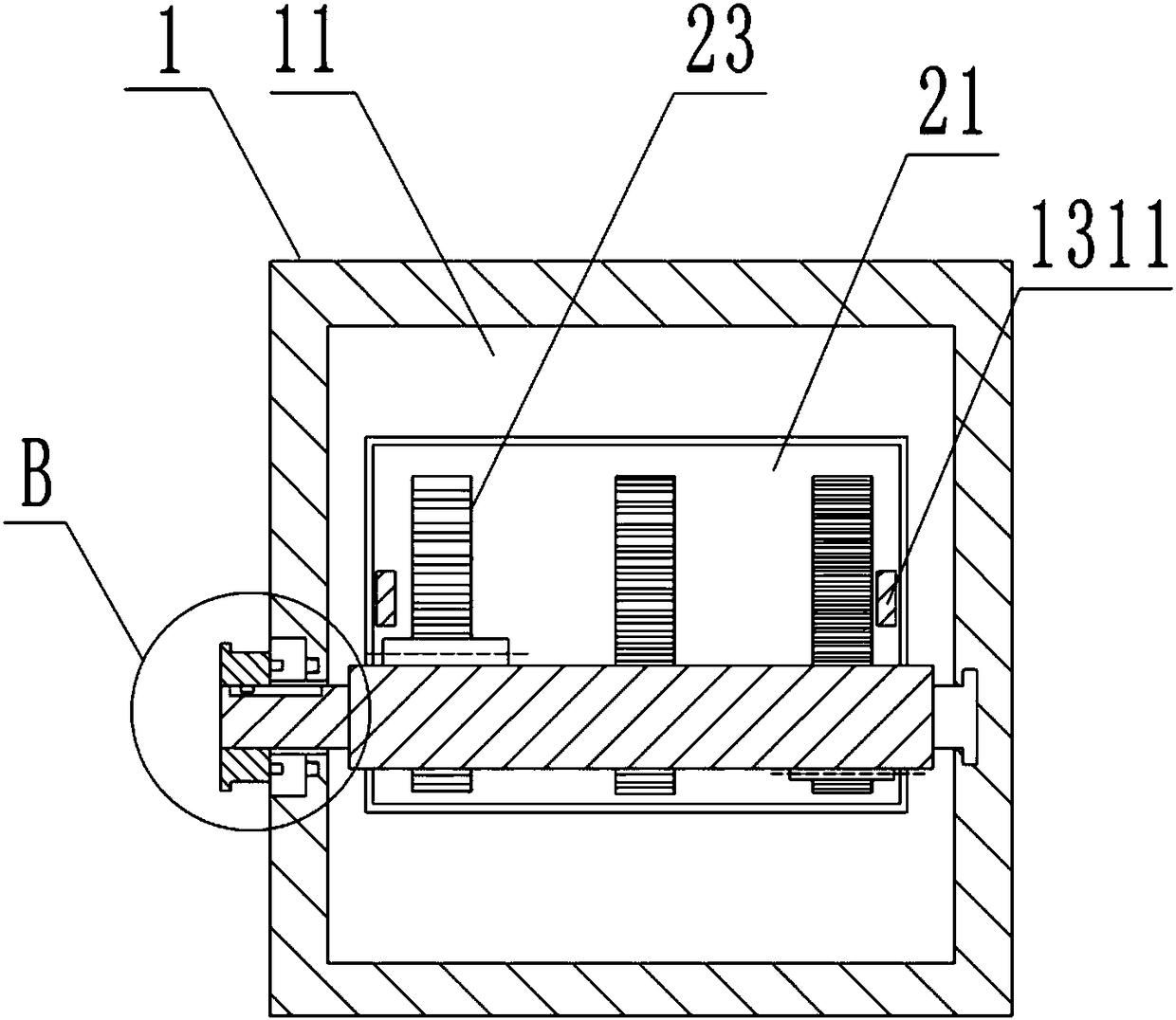

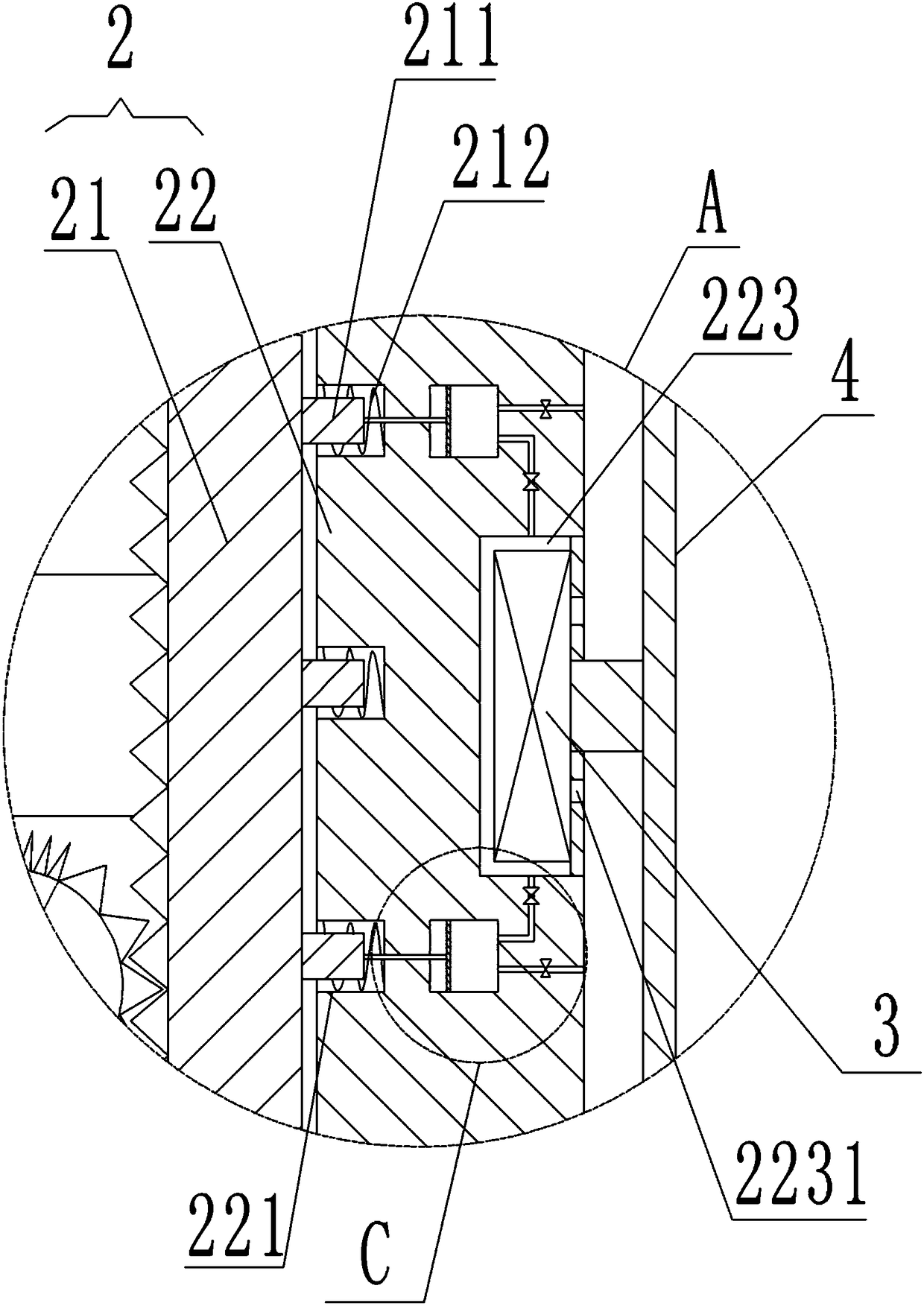

[0027] The reference signs in the accompanying drawings of the description include: fixed seat body 1, cavity 11, rotating shaft 111, arc-shaped rack 112, large-scale adjustment rack 1121, small-range adjustment rack 1122, fine-tuning rack 1123, bar-shaped mouth 12. Button cavity 13, button plate 131, button rod 1311, button spring 132, slide bar 14, chute 141, return spring 142, slide plate 2, first plate 21, ejector rod 211, ejector rod spring 212, second Plate 22, linear rack 23, pressing chamber 221, inflating part 222, air cylinder 2221, piston 2222, piston rod 2223, air blowing pipe 2224, air intake pipe 2225, motor cavity 223, cooling channel 2231, motor 3, cutter 4, handle 5. Hand-held plate 51, sliding protrusion 511, positioning protrusion 512, connecting rod 52, strip chute 521, positioning cavity 6, groove 61, wedge-shaped block 62.

[0028] In order to achie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com