Protective sleeve and manufacturing method thereof

A technology for protecting casing and manufacturing method, which is applied in the direction of pipeline protection, pipe/pipe joint/pipe fitting, pipeline damage/wear prevention, etc., to achieve the effect of increasing the ability to resist compression and increasing tissue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The preferred embodiments of the invention will be further described in detail below.

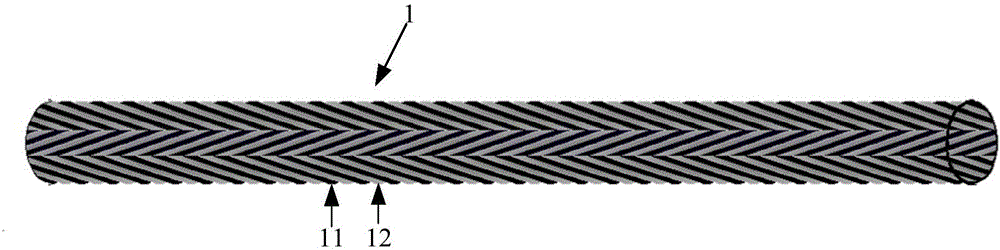

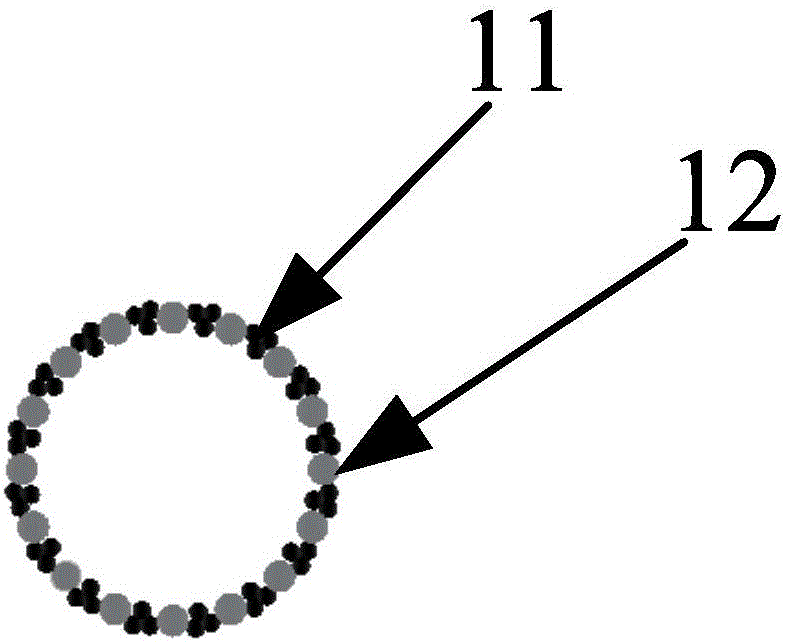

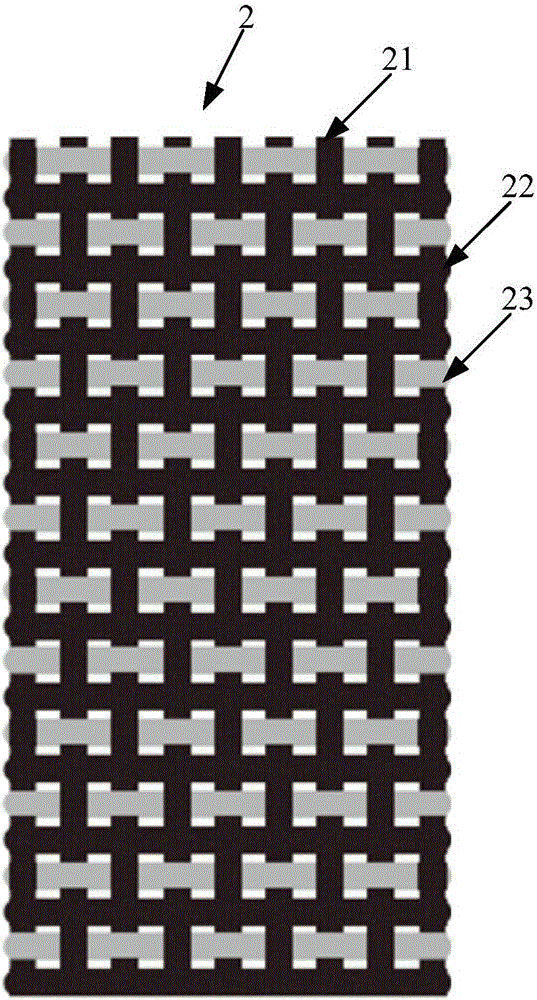

[0022] Such as figure 1 As shown, a protective sleeve 1 of an embodiment includes a plastic wire 11 and a plastic thermal fuse 12, the melting point of the plastic wire 11 is higher than the melting point of the plastic thermal fuse 12, and the protective sleeve 1 is composed of The plastic wire 11 and the plastic thermal fuse 12 are woven, for example, as figure 1 and 2 As shown, the plastic wire 11 and the plastic thermal fuse 12 can be mixed and braided (that is, the plastic wire 11 and the plastic thermal fuse 12 intersect each other and are woven with a cross structure); image 3 As shown, also can utilize described plastic thread 21 and plastic thermal fuse 23 to weave and form and obtain protective sleeve 2 (that is, described plastic thread 21 and plastic thermal fuse 23 are used as warp and weft respectively, adopt warp and weft structure to weave and form into), in one e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com