Turbulence intensified heat transfer device for dynamically controlling cylindrical vortex generator and working method of turbulence intensified heat transfer device

A vortex generator, dynamic control technology, applied in the direction of heat transfer modification, heat exchange equipment, lighting and heating equipment, etc., can solve the problems of changing the vortex generator, can not meet the requirements, energy consumption, etc., to reduce the vibration frequency and/or amplitude, improve overall heat transfer performance, enhance the effect of fluid disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0024] The dynamic control turbulence generator heat transfer enhancement structure of the heat exchanger for high-intensity heat exchange with dynamic change of heat flux of the present invention is based on the traditional fixed vortex generator structure combined with the existing turbulent heat transfer principle And the heat transfer structure improved by the principle of dynamic mechanical control.

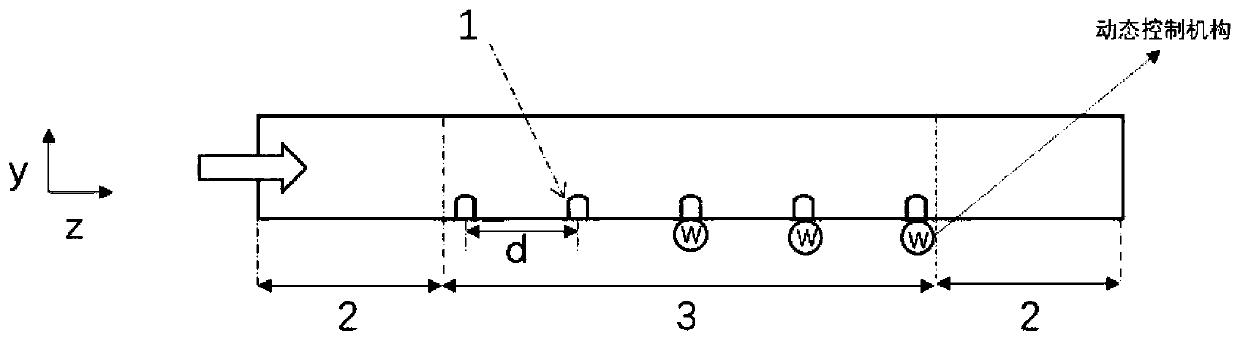

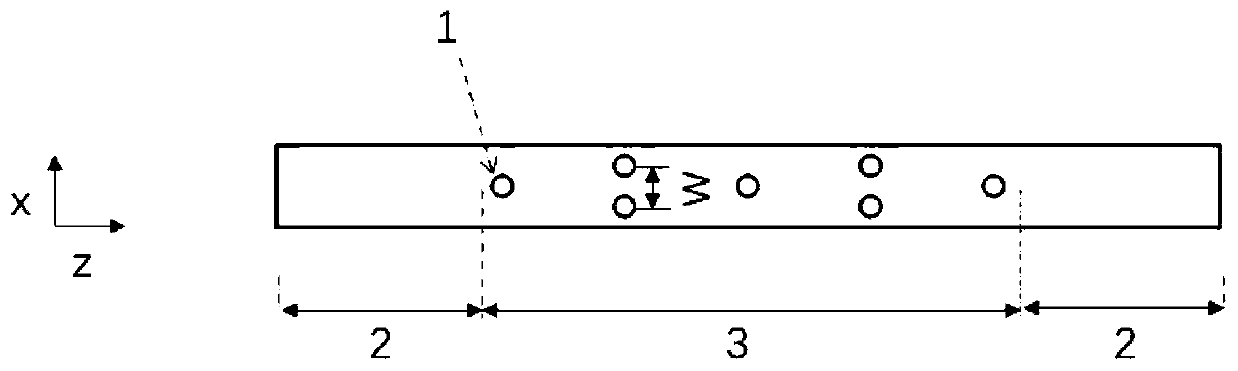

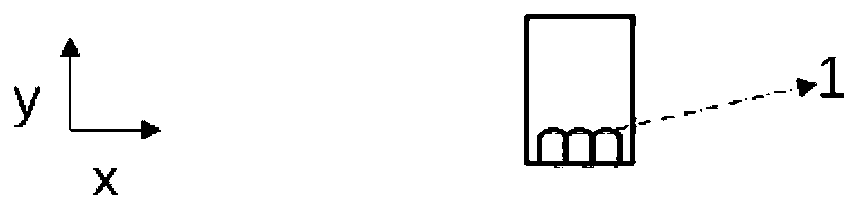

[0025] combine Figure 1-3 , a turbulence enhanced heat transfer device for dynamically controlling a cylindrical vortex generator, comprising a cylindrical vortex generator 1, a sealing device 4 and a dynamic control structure, the cylindrical vortex generator 1 includes a plurality of rows of cylinders arranged on a heat transfer surface , the number of cylinders in each row is at least one, the bottom of each cylinder is connected to a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com