Liquid lead-bismuth environment static soaking test device and test method

A technology of static immersion and test equipment, which is applied in the direction of measuring equipment, instruments, scientific instruments, etc., and can solve problems such as potential safety hazards and corrosion structures of liquid lead-bismuth alloys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

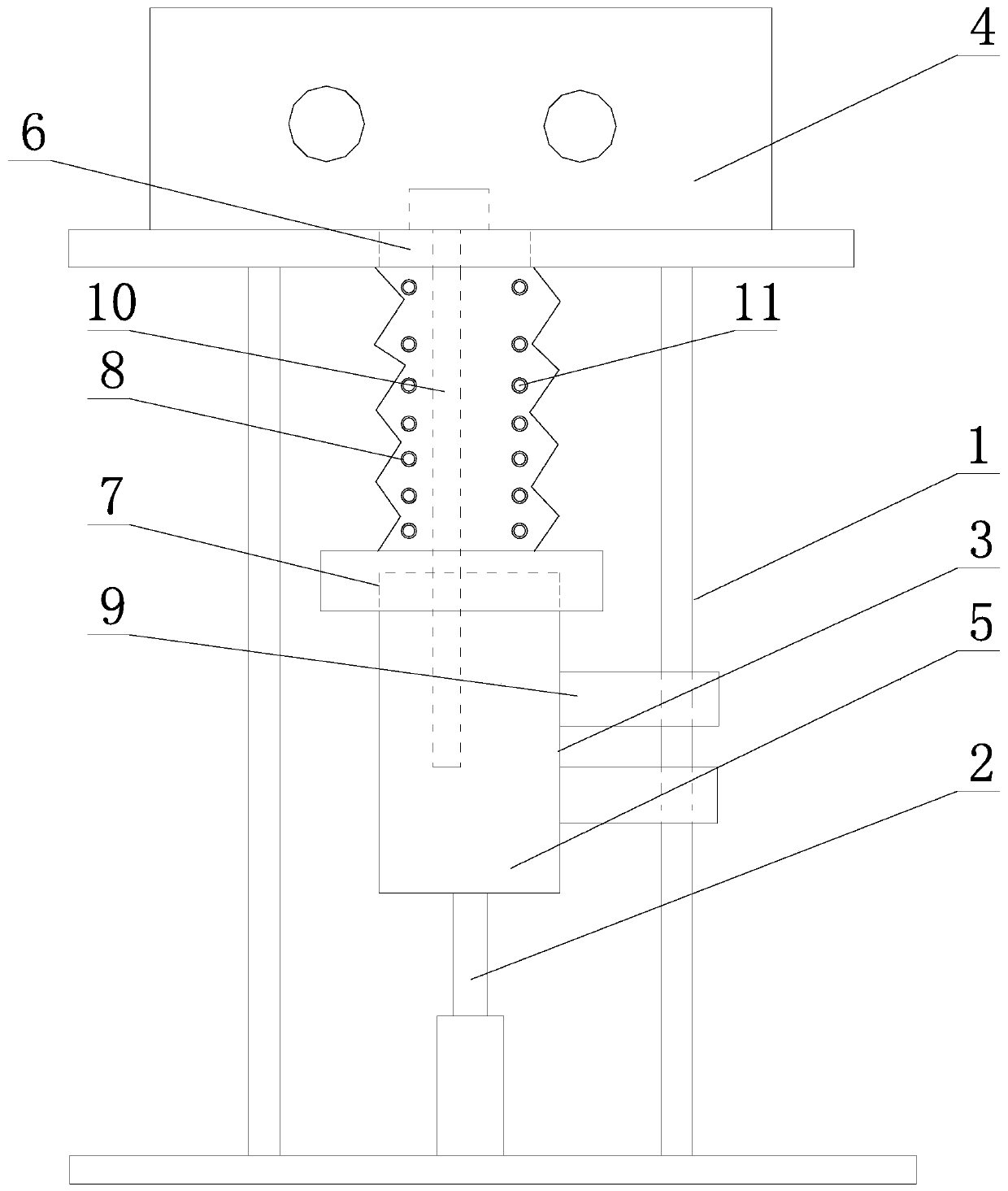

[0050] like figure 1 As shown, a static immersion test device for liquid lead and bismuth environment, the device includes a frame 1, a test kettle 3, the mouth of the test kettle 3 faces upward, and also includes a lifting device 2 and a bellows 8, and the bellows The upper end of the bellows 8 is connected to the frame 1, and the lower end of the bellows 8 is docked with the mouth of the kettle;

[0051] The output end of the lifting device 2 is connected with the test kettle 3, and the lifting device 2 is used to drive the test kettle 3 to move up and down to change the height of the test kettle 3 in space, and the test kettle 3 occurs the described During the lifting and lowering movement, the bellows 8 is compressed or stretched along with the movement of the test kettle 3 .

[0052] In the prior art, to complete the corrosion test of materials in a specific environment, it is generally sufficient to simulate the required corrosion environment. When conducting corrosion ...

Embodiment 2

[0066] like figure 1 As shown, the present embodiment is further limited on the basis of embodiment 1:

[0067] In order to make the lifting device 2 work, the bellows 8 only shrinks or is elongated, so as to avoid lateral interference when the corresponding sensor and the sample hanger 10 are installed vertically, it is set as follows: the bellows 8 , The axial direction of the test kettle 3 is located in the vertical direction, and under the action of the lifting device 2, the movement direction of the test kettle 3 is located in the vertical direction.

[0068] As mentioned above, this solution takes into account the environmental pollution problems caused by the experimental process. Further, it is set to: it also includes an inner cover 6 and a kettle cover 7. The inner cover 6 is arranged at the opening position of the upper end of the bellows 8. The inner cover 6 It is used to close the upper end of the bellows 8; the kettle cover 7 is arranged at the still mouth of th...

Embodiment 3

[0075] like figure 1 As shown, this embodiment provides a more detailed implementation on the basis of any one of the technical solutions provided in the above embodiments:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com