Measurement and compensation calibration method for full-focus phased array three-dimensional ultrasonic field

A calibration method, three-dimensional ultrasonic technology, applied in measuring devices, using sound waves/ultrasonic waves/infrasonic waves to analyze solids, using sound waves/ultrasonic waves/infrasonic waves for material analysis, etc., can solve problems that are difficult to learn, difficult to master, complicated to operate, and slow to calibrate, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0090] Further description will be given below in conjunction with the accompanying drawings and preferred embodiments of the present invention.

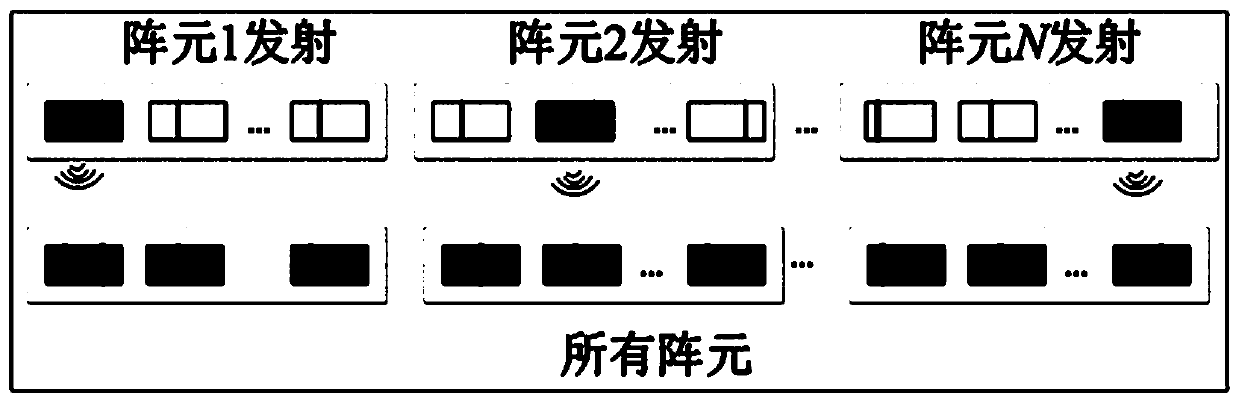

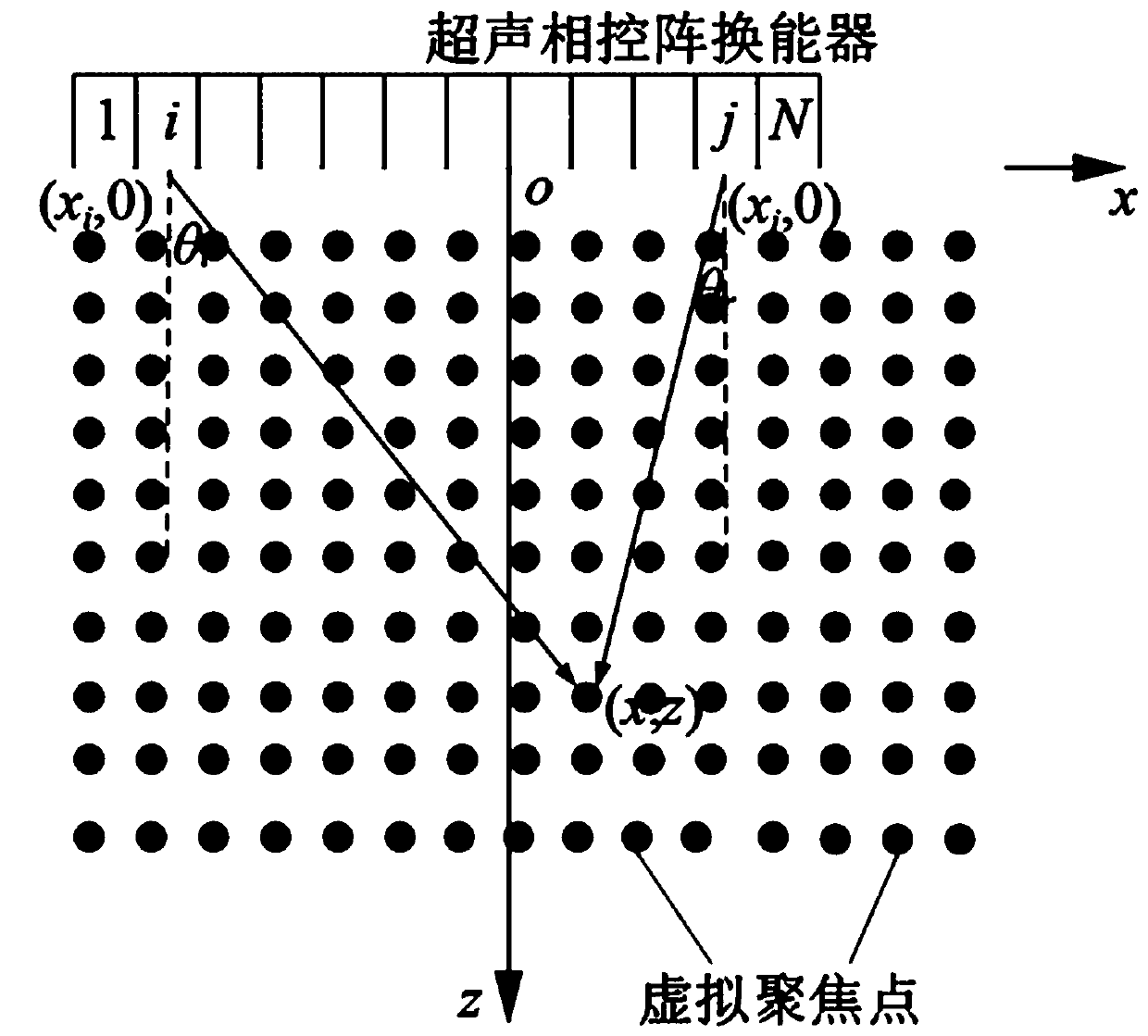

[0091] The method for measuring and compensating and calibrating an all-focus phased array three-dimensional ultrasonic field includes the following steps:

[0092] Step (a), select the metal test block 1 with clustered spherical bottom horizontal holes with the same thickness as the weld to be tested; Figure 6-Figure 9 As shown, the clustered spherical bottom horizontal hole metal test block 1 has a horizontal scanning surface 101 and a vertical perforated surface 102 perpendicular to the horizontal scanning surface. The vertical perforated surface 102 is provided with three rows and four rows of cylindrical spherical bottoms. Hole 103, the length direction of the cylindrical spherical bottom hole 103 extends along the horizontal direction, the bottom of the cylindrical spherical bottom hole 103 is a hemispherical concave surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com