Automatic liquid dropping machine

A dripping and automatic technology, which is applied in the direction of program control in instruments, sequence/logic controllers, and advertisements, can solve the problems of consumers experiencing cosmetics, increasing the workload of on-site staff, and unstable service quality. The effect of stable quality, reduced workload and precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

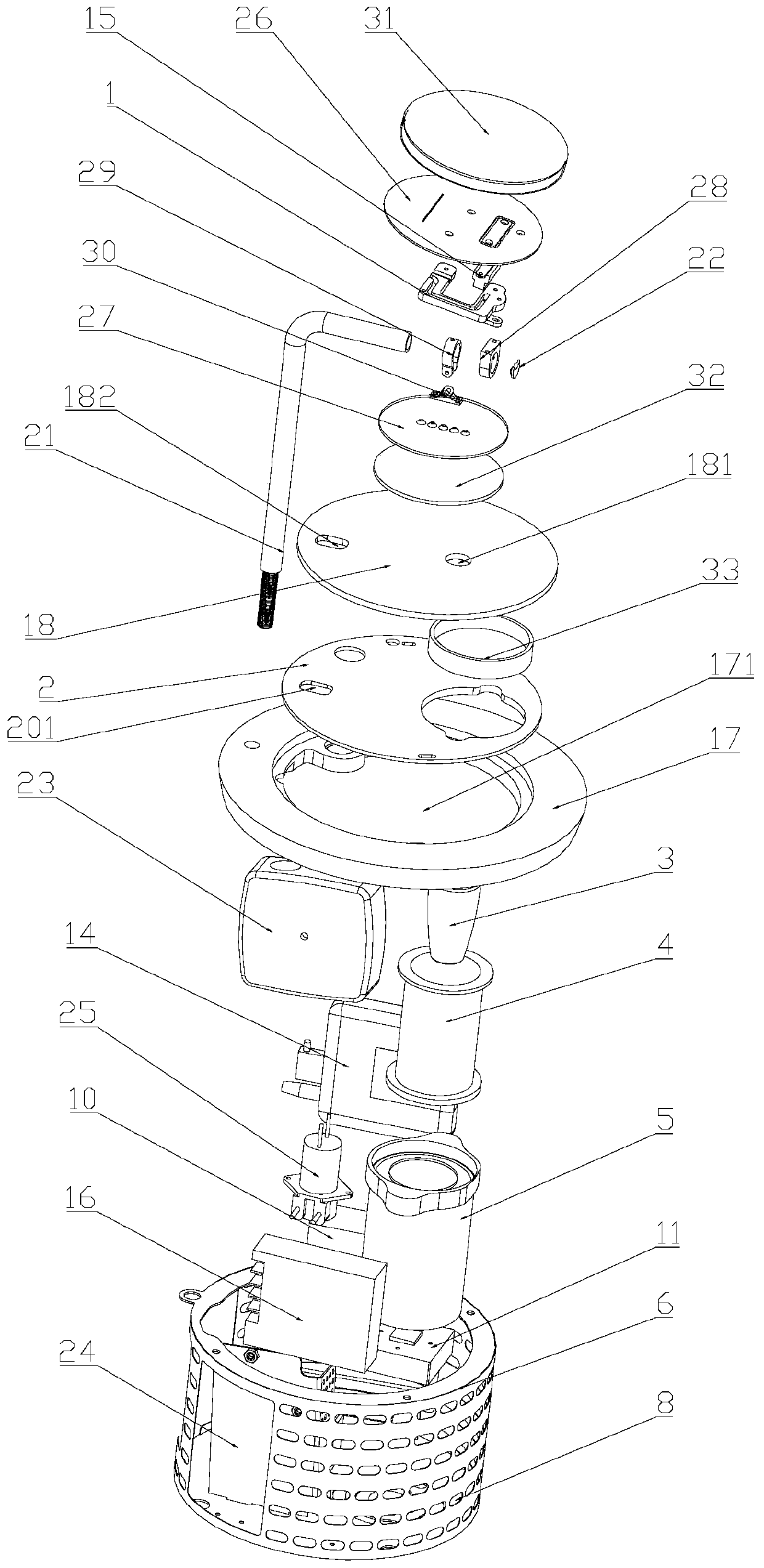

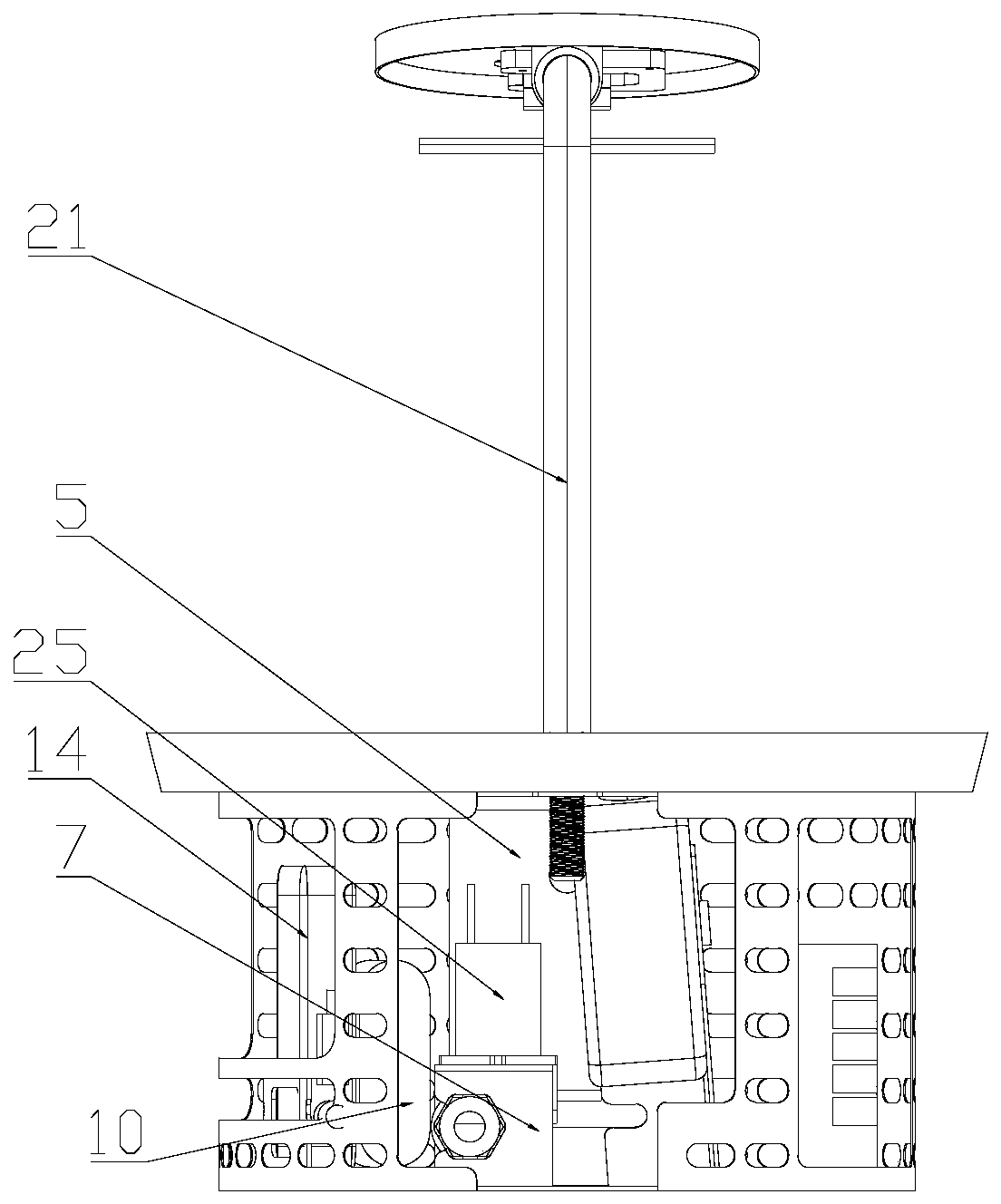

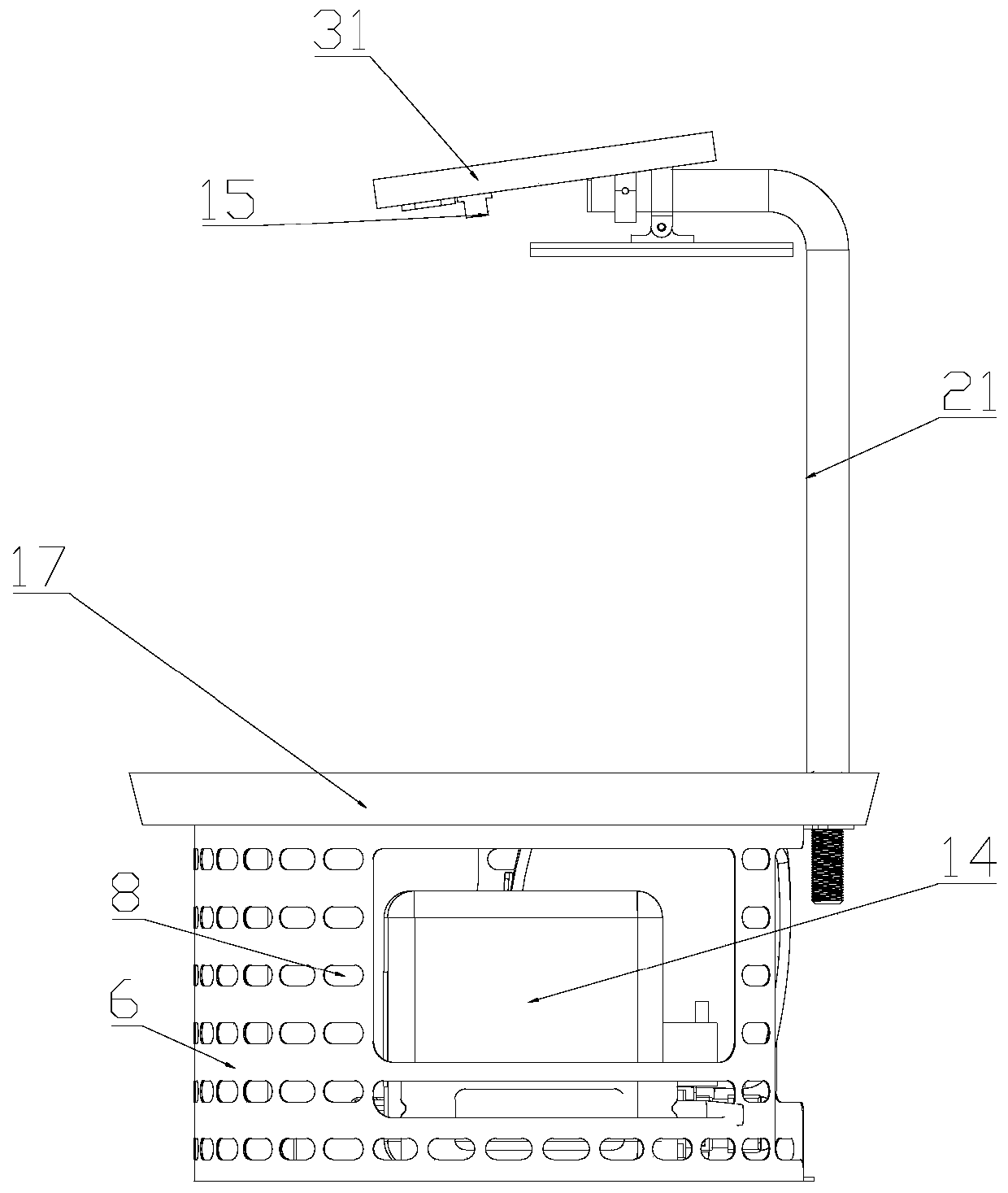

[0033] like figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, an automatic dripping machine includes a casing 6, and the casing 6 is provided with a transformer power supply 16, a display device bracket 24, a peristaltic pump bracket 7, a controller 10 and a player bracket 20 in sequence.

[0034] The display device bracket 24 is provided with a display device for adjusting the angle by screws.

[0035] The peristaltic pump support 7 is provided with a peristaltic pump 25 .

[0036] The player bracket 20 is provided with a player 14 electrically connected to the display device and the controller 10 respectively.

[0037] The housing 6 on one side of the peristaltic pump support 7 is provided with a radiator 11, and the radiator 11 is provided with a heat-insulating protective shell 5, and a bottle support 4 is arranged in the heat-insulating protective shell 5. The lotion bottle 3 connected with the peristaltic pump 25 and the radiator 11 can keep the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com