Balance control module life prediction method and device based on health indexes

A technology of balanced control and health indicators, applied in general control systems, control/regulation systems, test/monitoring control systems, etc., can solve problems such as prediction of remaining service life of difficult systems, aging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] This embodiment discloses a method for predicting the life of a balance control module based on health indicators, including the following steps:

[0072] Step S1: Based on the data of the brake balance control module in each action, extract its eigenvalues at each action;

[0073] Step S2: Construct a health index model, determine the model parameters based on the eigenvalues of the samples of the brake balance control module; and based on the extracted eigenvalues, use the health indicator model after parameter determination to calculate Health indicators at the time;

[0074]Step S3: Construct a life prediction model, based on the health index sequence and the remaining service life sequence of the samples of the brake equalization control module (marking the remaining service life of each sample in each action = the total action of the sample in the entire life cycle Number of times - the number of actions the sample has performed during this action, such as th...

Embodiment 2

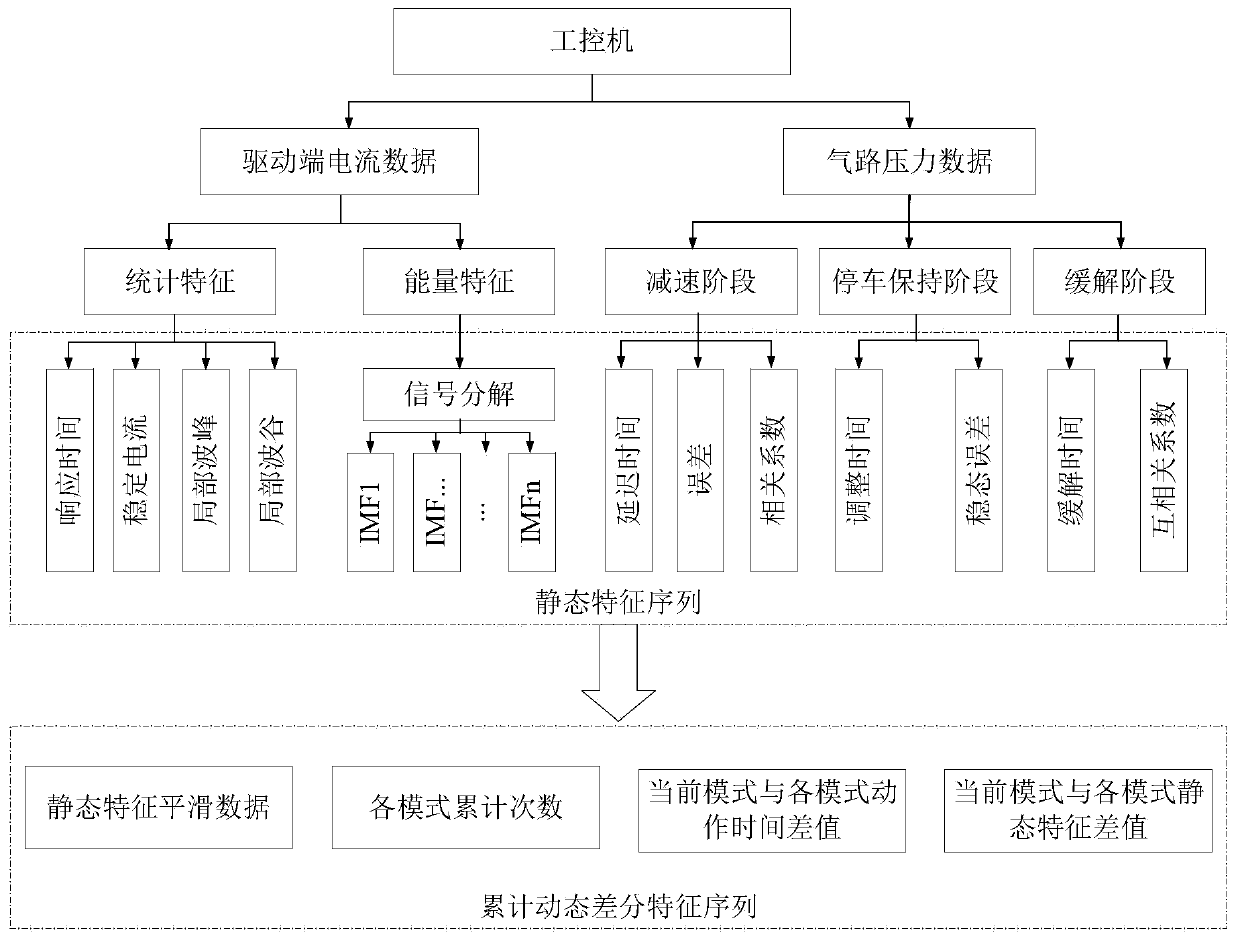

[0077] This embodiment is on the basis of embodiment 1, as figure 1 As shown, the feature extraction in the step S1 specifically includes the following steps:

[0078] Step S1.1, extracting static features:

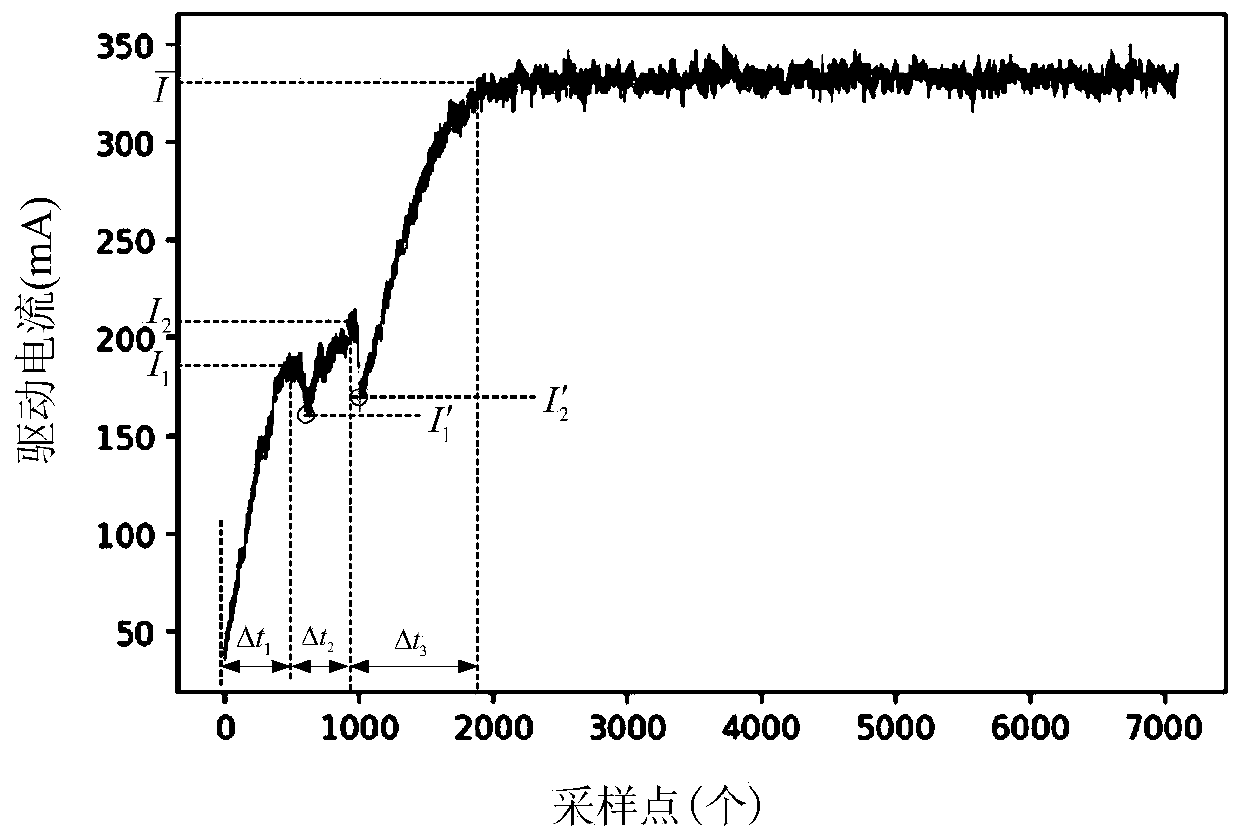

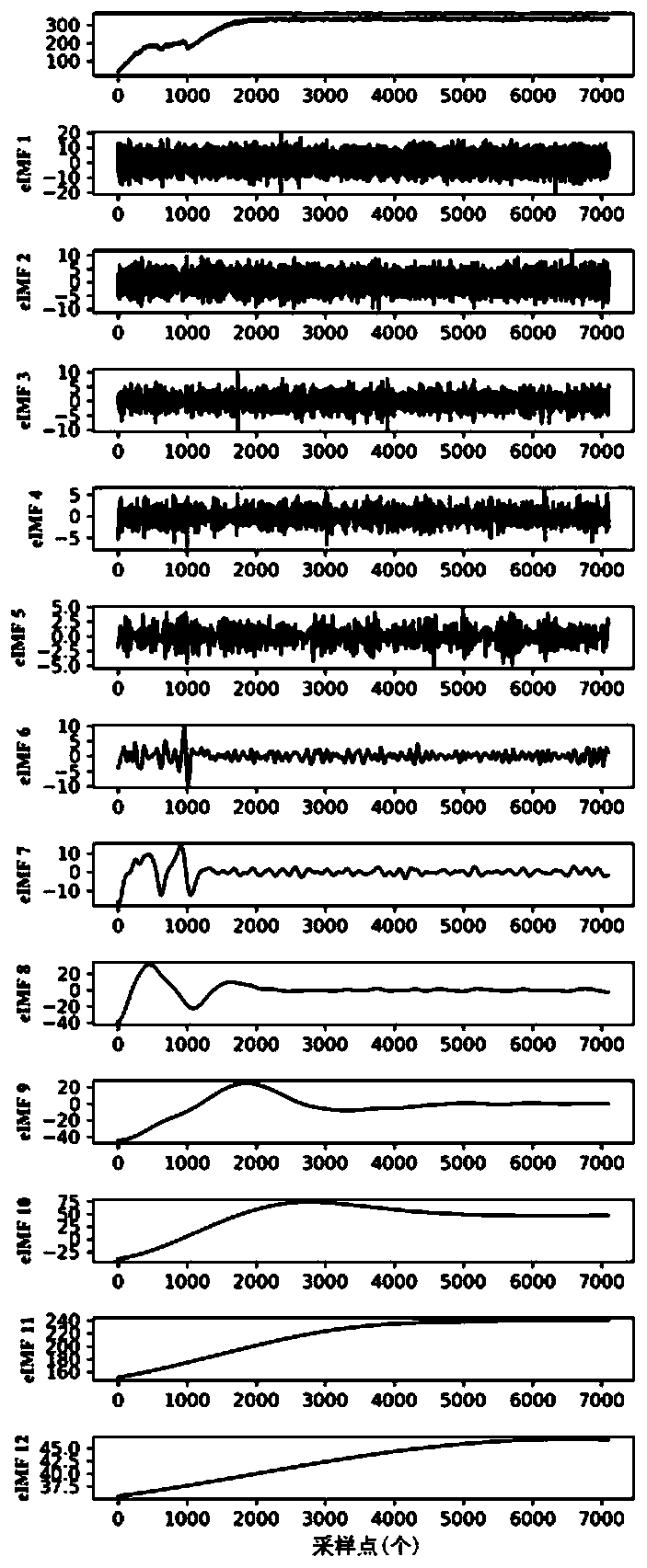

[0079] Based on the driving current curve of each solenoid valve in each action of the brake balance control module, a set of aging characteristics of the solenoid valve is extracted. The aging characteristics of the solenoid valve include the statistical characteristics and energy characteristics of the driving current; the statistical characteristics of the driving current include the response time Δt, local peak value I, local valley value I', stable current value Among them, the energy characteristic is to use the empirical mode decomposition to decompose the driving current curve into Z intrinsic mode function components And the calculated components of each intrinsic mode function energy e z ,Calculated as follows:

[0080]

[0081] Where L is the number ...

Embodiment 3

[0096] This embodiment is based on Embodiment 1. In the step S2, the health index model is aimed at obtaining the health index representing the aging state (system degradation trend) of the balance control module by fusing the accumulated dynamic feature sequence. Considering that the cumulative dynamic feature F consists of each part (F 1 ,F 2 ,F 3 ,F 4 ) are multi-dimensional, let K be the total dimension of the cumulative dynamic feature, that is, the number of features it contains, then the cumulative dynamic feature corresponding to the t-time action of the balance control module can be expressed as F(t)=(f 1 (t), f 2 (t),...,f K (t)), the health index is expressed as a linear combination of features, that is, the constructed health index model is:

[0097] H(t)=w 1 f 1 (t)+w 2 f 2 (t)+...w k f k (t)+...+w K f K (t)

[0098] Among them, H(t) is the health index of the balance control module at the tth action, w 1 ,w 2 ,...,w k ,...,w K Indicates the weig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com