Vehicle body assembly tolerance distribution method

An allocation method and assembly tolerance technology, applied in image data processing, 3D modeling, instruments, etc., can solve the problems of not considering the influence of welding deformation and the lack of accuracy and effectiveness of tolerance allocation, so as to improve accuracy and effectiveness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In the process of realizing the present application, the inventor found that the existing dimensional chain tolerance allocation method of the car body only analyzes the rigid dimensional chain in the assembly process, and does not consider the influence caused by welding deformation in the assembly process, resulting in the existing The tolerance assignment of the bodywork lacks accuracy and effectiveness.

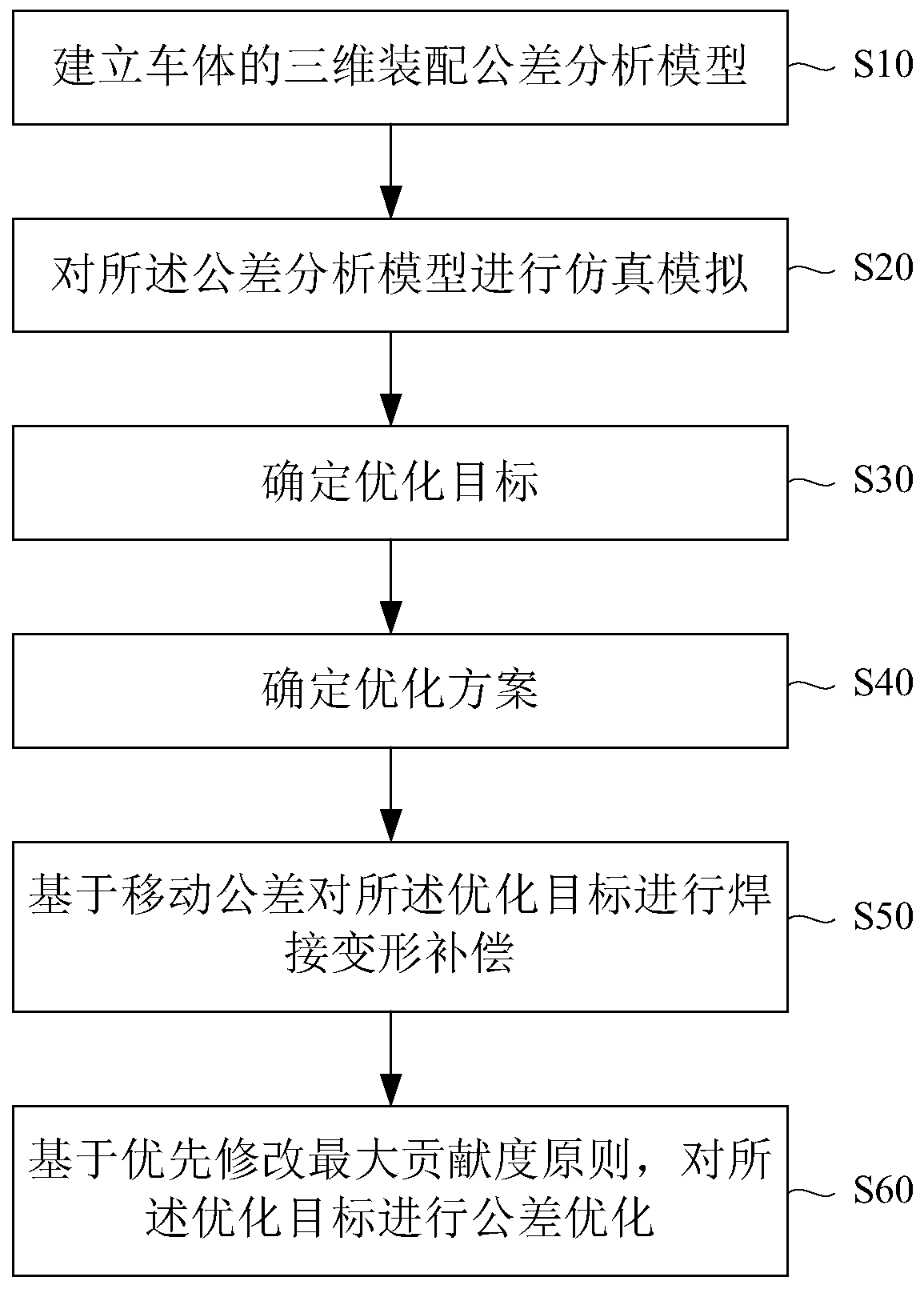

[0032] In view of the above problems, the embodiment of the present application provides a vehicle body assembly tolerance allocation method. The tolerance allocation method simulates the established three-dimensional assembly tolerance analysis model, determines the optimization goal and optimization plan through the simulation simulation, and considers In the case of welding deformation, the welding deformation is compensated by moving tolerances. This tolerance allocation method not only analyzes the rigid dimension chain, but also considers the influence of weld...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com