Holding tool device for automatically stacking fuel cell stacks

A fuel cell stack and automatic stacking technology, which is applied in the direction of fuel cells, circuits, electrical components, etc., can solve the problem that the small diameter of the positioning mechanism is difficult to ensure the accuracy of straightness, etc., the automatic stacking of stack materials has not been realized, and the automatic production and assembly cannot be applied and other problems, to achieve the effect of simple structure, stable transmission and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

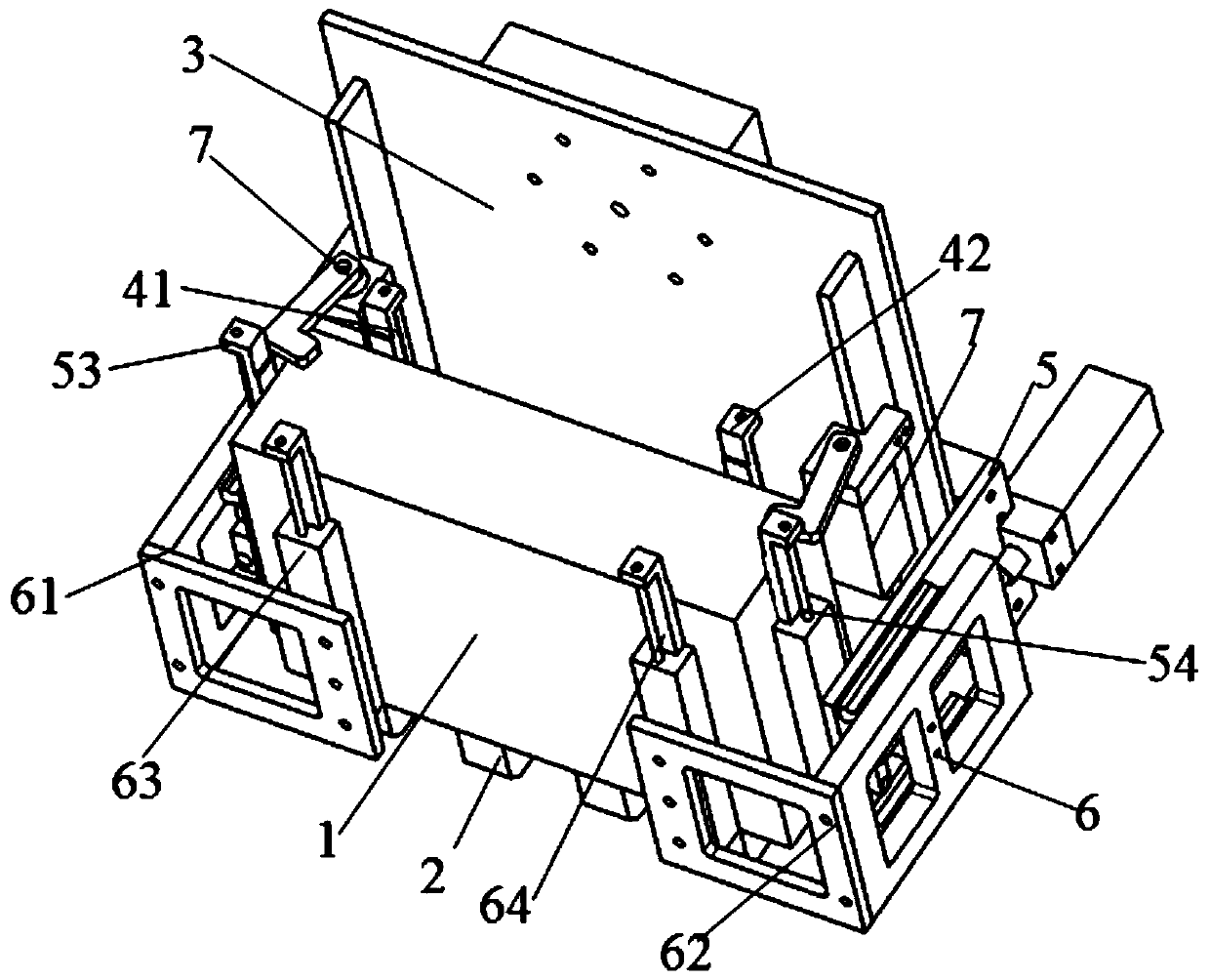

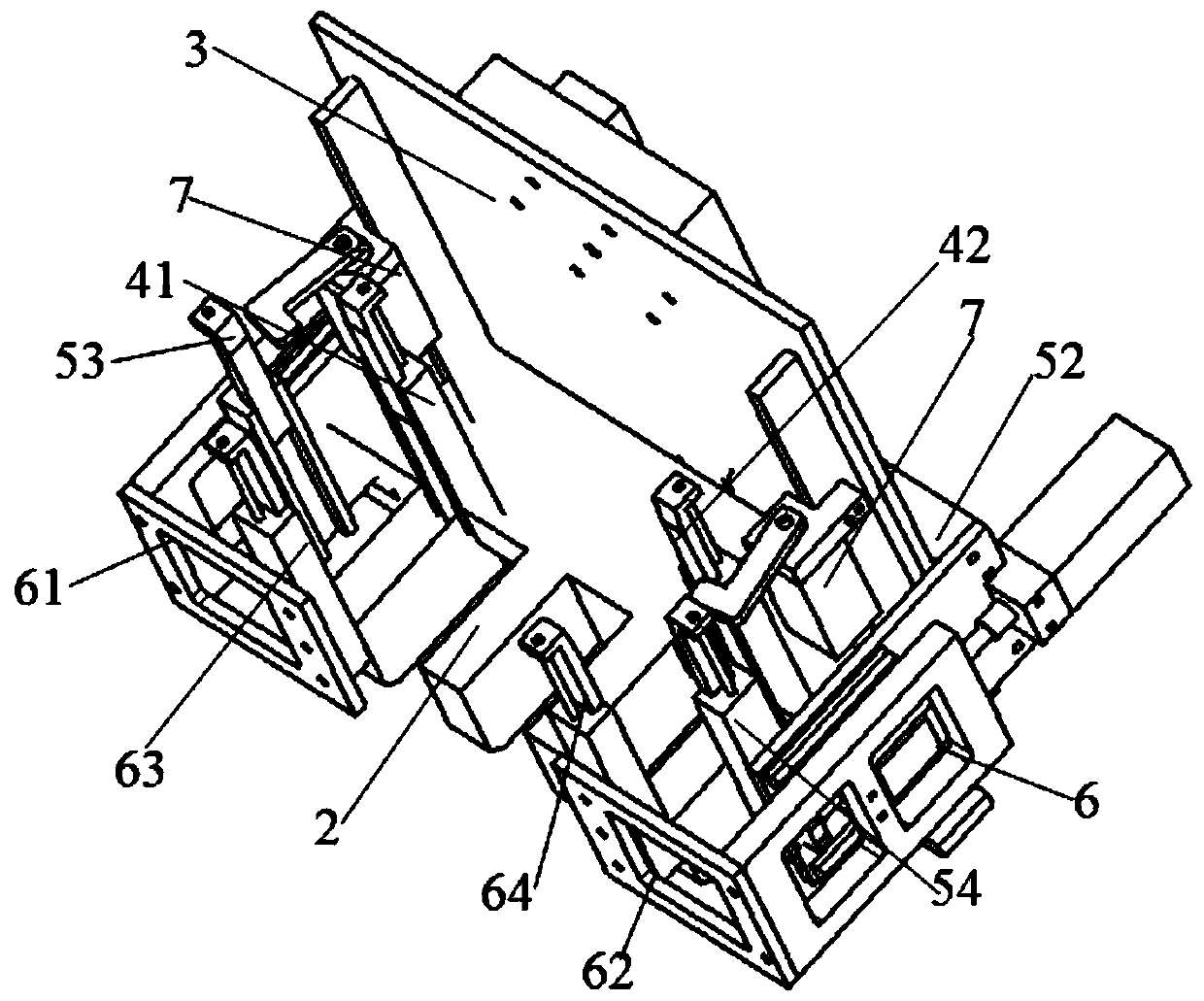

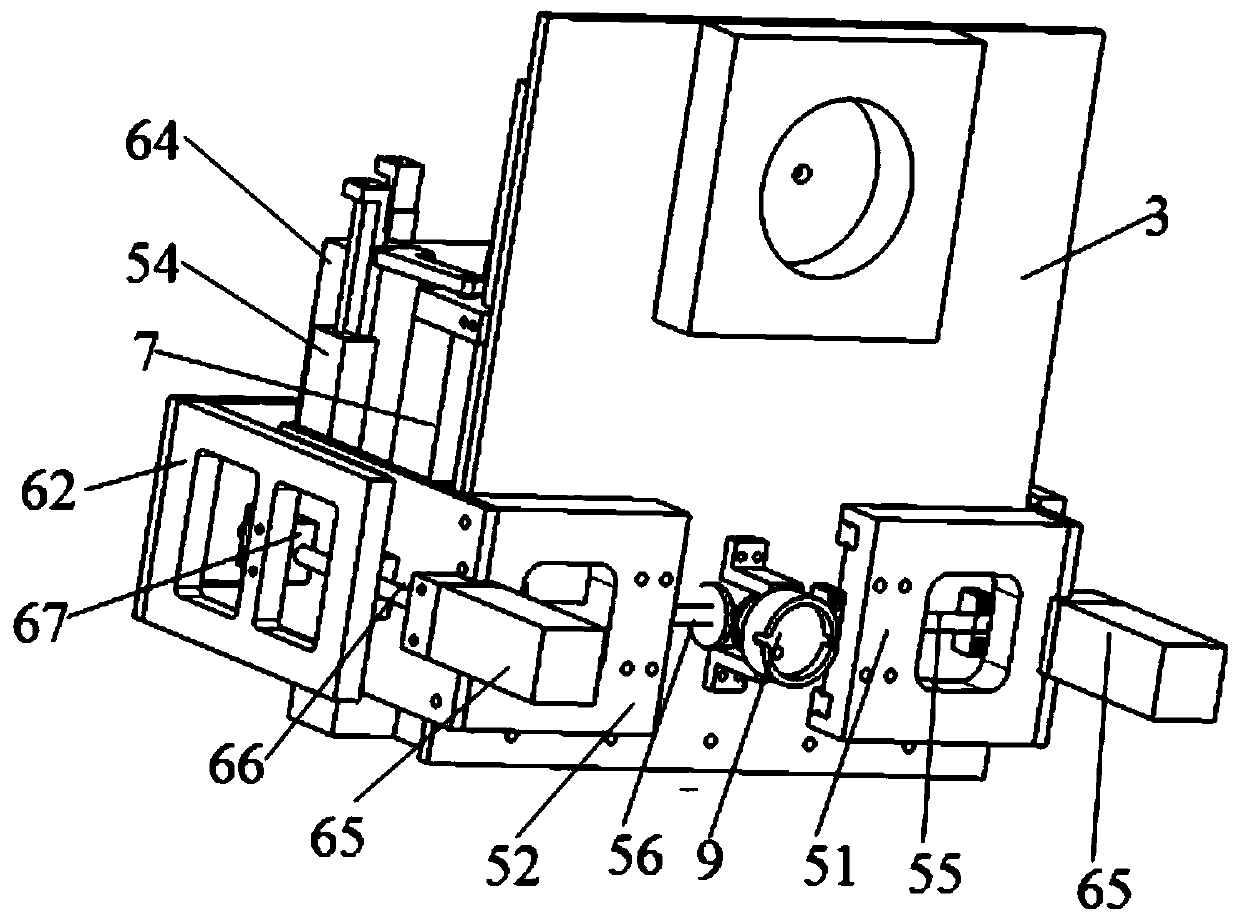

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0033] like Figure 1-7 As shown, the present invention provides a holding device for automatic stacking of fuel cell stacks, including a base plate 2 for placing the stack 1 and a back plate 3 fixedly connected to the base plate 2. A plurality of fixed base columns 4 arranged at intervals in the horizontal direction, the back plate 2 is provided with a first guide mechanism 5 that can be opened and closed horizontally, and cooperates with the lateral sides of the stack 1 to limit the position, the first guide mechanism 5 is in front of the fixed base column 4 There is a second guide mechanism 6 that can move longitudinally. The second guide mechanism 6 and the fixed base column 4 cooperate with the longitudinal sides of the electric stack 1 to limit the positions. Tight mechanism7. In this embodiment, the transverse direction is th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com