Gas treatment device

A gas treatment and gas technology, applied in the direction of gas treatment, combined devices, transportation and packaging, etc., can solve the problems of excessive sewage, high device operating costs, and high consumption, and achieve purification cost reduction, extended life, and good gas treatment effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

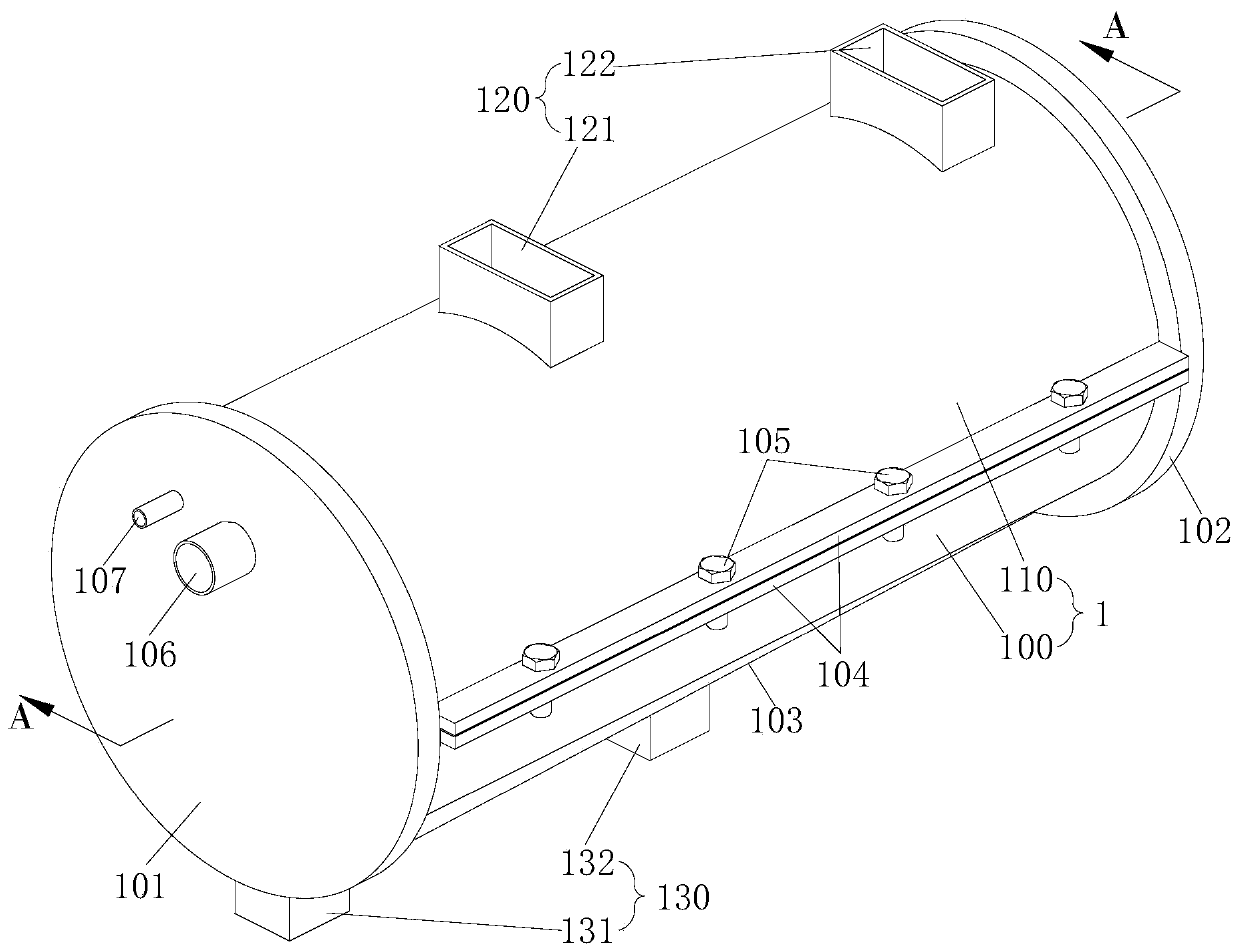

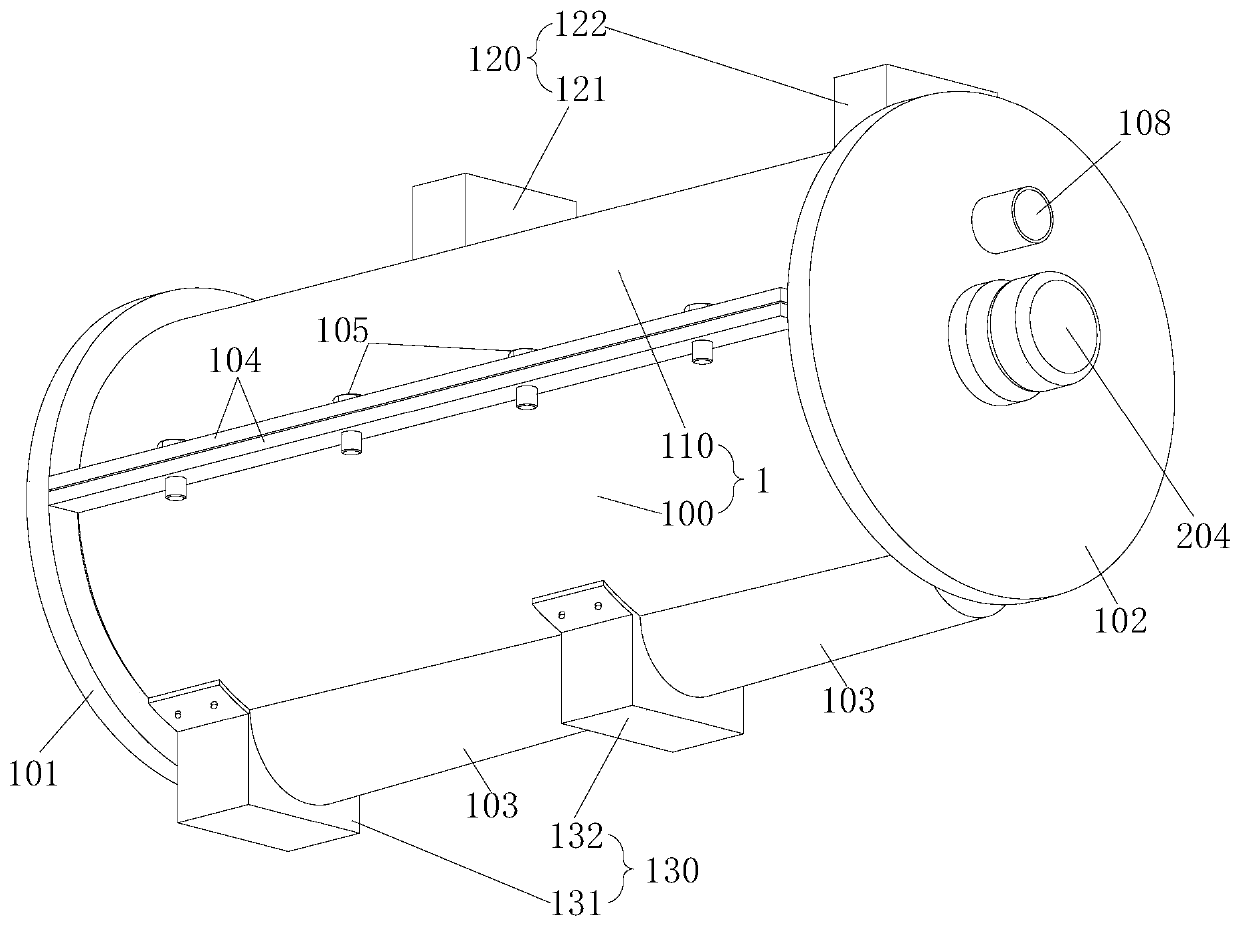

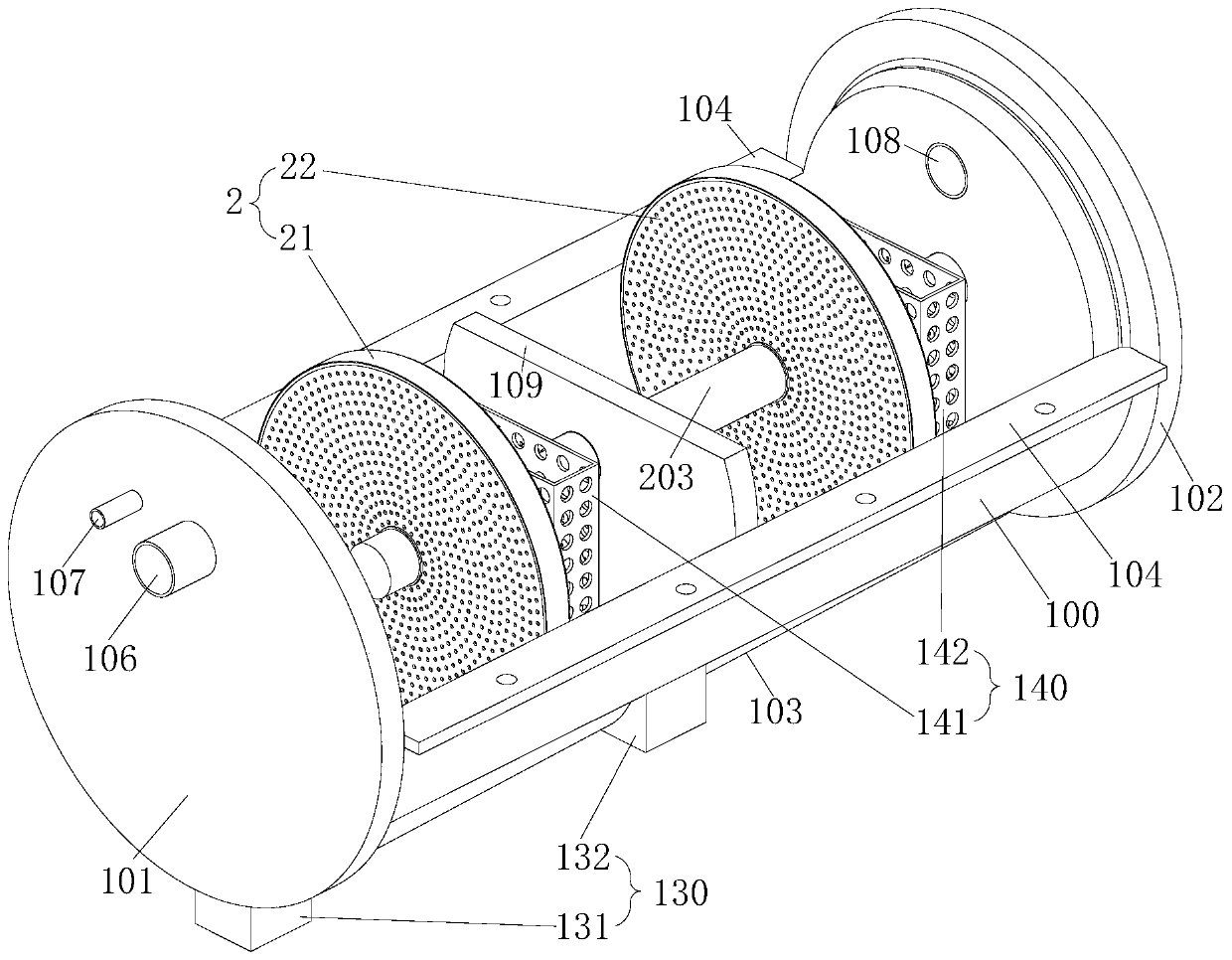

[0040] This embodiment relates to a gas treatment device, which can prolong the service life of the filter material in the gas treatment device, thereby reducing the cost of gas treatment and purification. The gas treatment device has a cavity formed by a casing and a filter unit arranged in the cavity, and the two ends of the casing are respectively provided with an air inlet and an exhaust for gas to enter and exit the cavity. port, the filter unit is driven to be rotatably separated between the air inlet and the exhaust port; the cavity is not fully filled with treatment liquid, and the filter unit is partially flushed by the treatment liquid In the middle; above the liquid level of the treatment liquid, a channel for the gas to flow through is formed; the gas passes through the filter unit soaked with the treatment liquid on the way of flowing through; because the filter unit The interception and / or the action of the treatment liquid constitutes the removal and separation ...

Embodiment 2

[0057] The cross-sectional structure of another structural form of the gas processing device described in this embodiment is as follows: Image 6 As shown, the housing 1 of the device is a cavity of a separate chamber, and a first filter unit 21, a second filter unit 22, a third filter unit 23, and a fourth filter unit 24 are sequentially arranged along the flow direction of the gas. Each filter unit 2, the filter level of four filter units 2 is increased sequentially, for example, the mesh size can be increased from 5 mesh to 40 mesh; or different filter materials can be used to remove corresponding harmful substances.

[0058] A spray head 150 can be installed above the upstream side of the first filter unit 21 to realize the preliminary spraying and dust removal of the gas. For the gas that needs to be supplemented with oxygen to react with the treatment liquid easily, it can be installed on the gas inlet side plate 101 Add air supply holes 107 for supplementing air. Only ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com