A device and method for induction heating assisted underwater laser cladding or material addition

An induction heating, underwater laser technology, applied in additive processing, laser welding equipment, metal processing equipment, etc., can solve oxidation and pores in the molten pool, reduce the stability of underwater local dry deposition/additive process, Problems such as accelerating the cooling rate of molten metal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

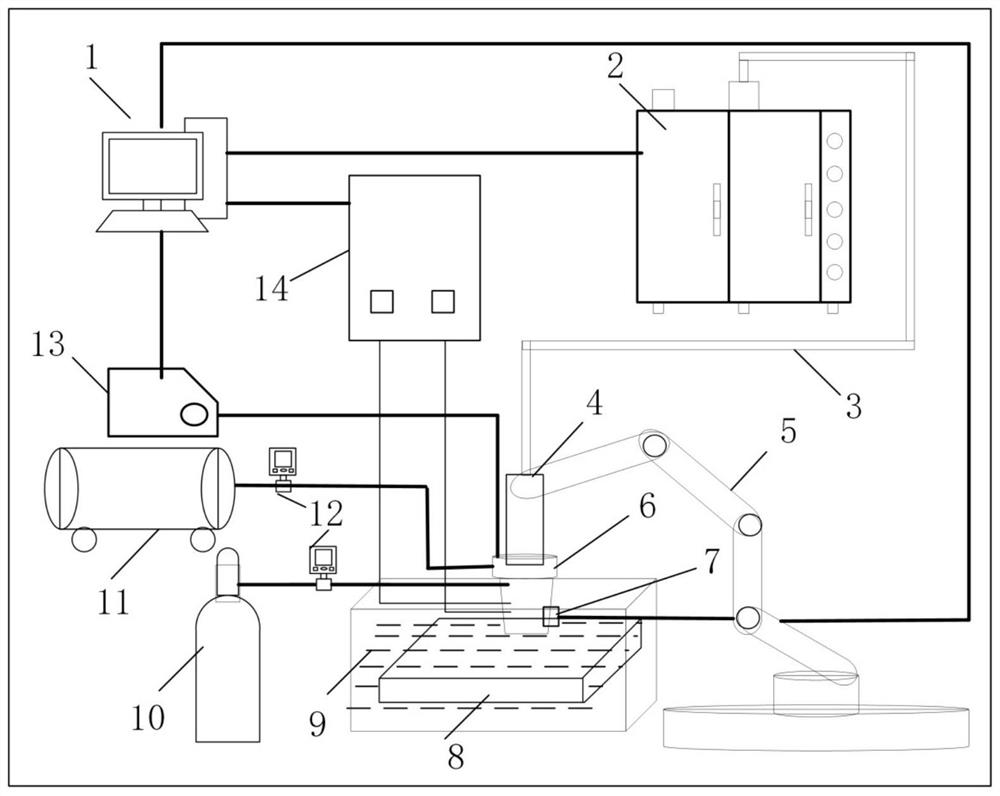

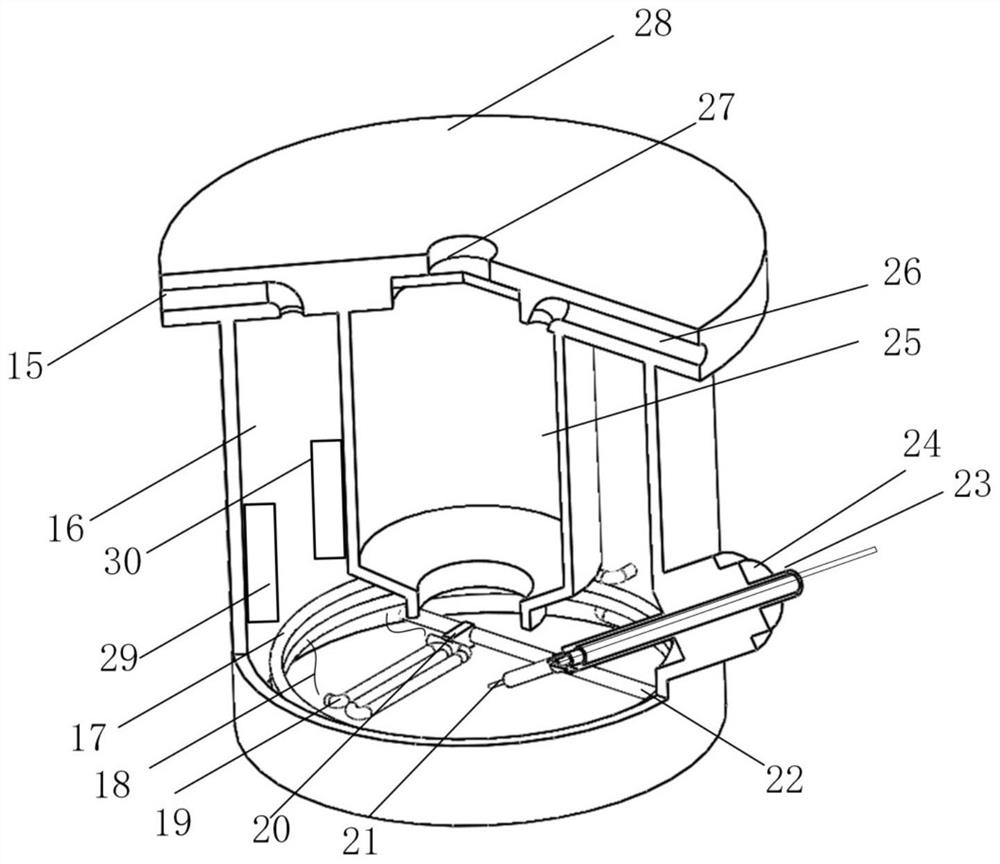

[0023] Such as figure 1 As shown, an induction heating-assisted underwater laser cladding or material addition device provided by the present invention includes a controller 1, and the controller 1 communicates with the laser 2, the robot 5, the wire feeder 13 and the induction heating machine 14 through the control system. Connected, the operation controller 1 can control the opening and closing and parameter adjustment of the laser 2; the opening and closing and wire feeding speed of the wire feeder 13; the opening and closing and parameter adjustment of the induction heating machine 14; and the three-dimensional movement of the robot 5 underwater. route plan. The laser 2 is connected to the laser head 4 through the optical fiber 3, and the laser welding torch 6 is fixed directly below the laser head 4. The laser beam generated by the laser 2 enters the laser head 4 through the optical fiber 3, and the laser beam enters the underwater after being adjusted by the laser head 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com