Automatic tray loading machine for magnetic material product, and implementation method of automatic tray loading machine

A magnetic material, pallet machine technology, applied in conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of product corner drop, increase in defect rate, labor consumption, etc., to achieve low cost of use, reduce defect rate, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

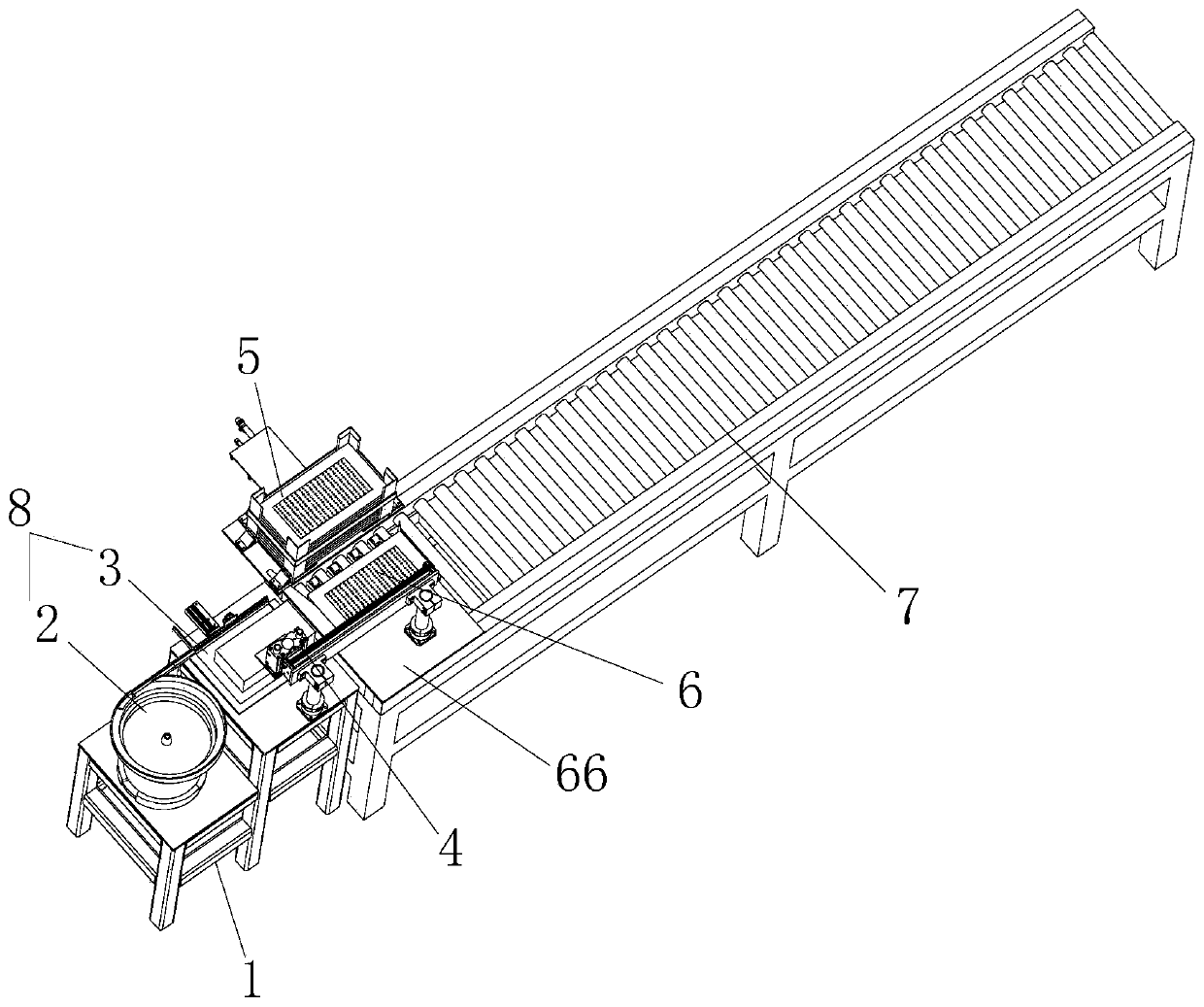

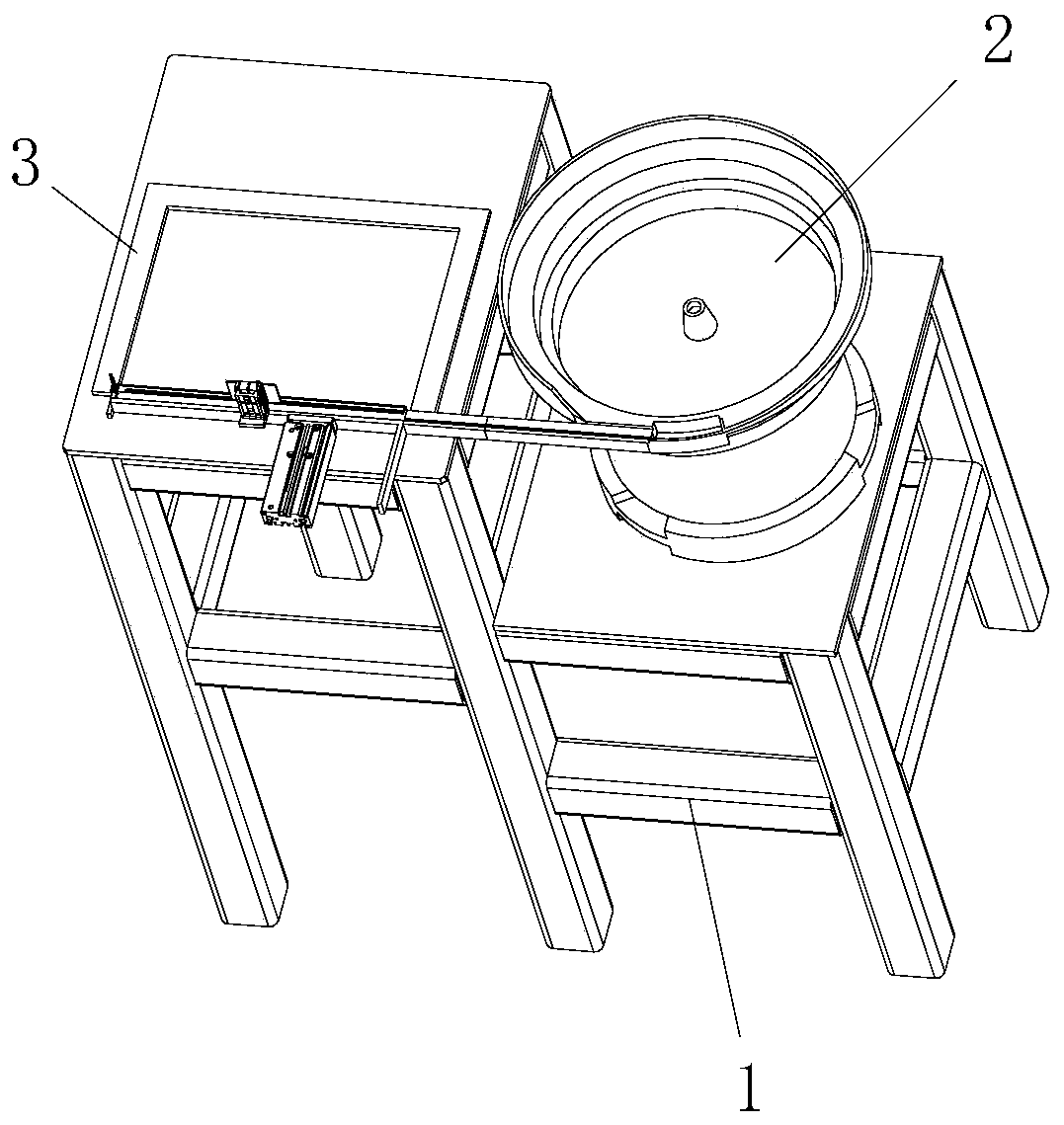

[0039] See Figure 1-7 , The present invention provides the following technical solutions: an automatic palletizing machine for magnetic material products, including a frame 1, a discharge mechanism 8 is arranged above the frame 1, and a conveyor line 7 and a conveyor line 7 are arranged on one side of the frame 1. A tray positioning mechanism 6 is provided on one end close to the frame 1, a transplanting mechanism 4 is provided between the discharging mechanism 8 and the tray positioning mechanism 6, and a tray separating mechanism 5 and a discharging mechanism 8 are provided on one side of the tray positioning mechanism 6 , The transplanting mechanism 4, the tray positioning mechanism 6, the tray separating mechanism 5 and the conveying line 7 are all signally connected to the controller.

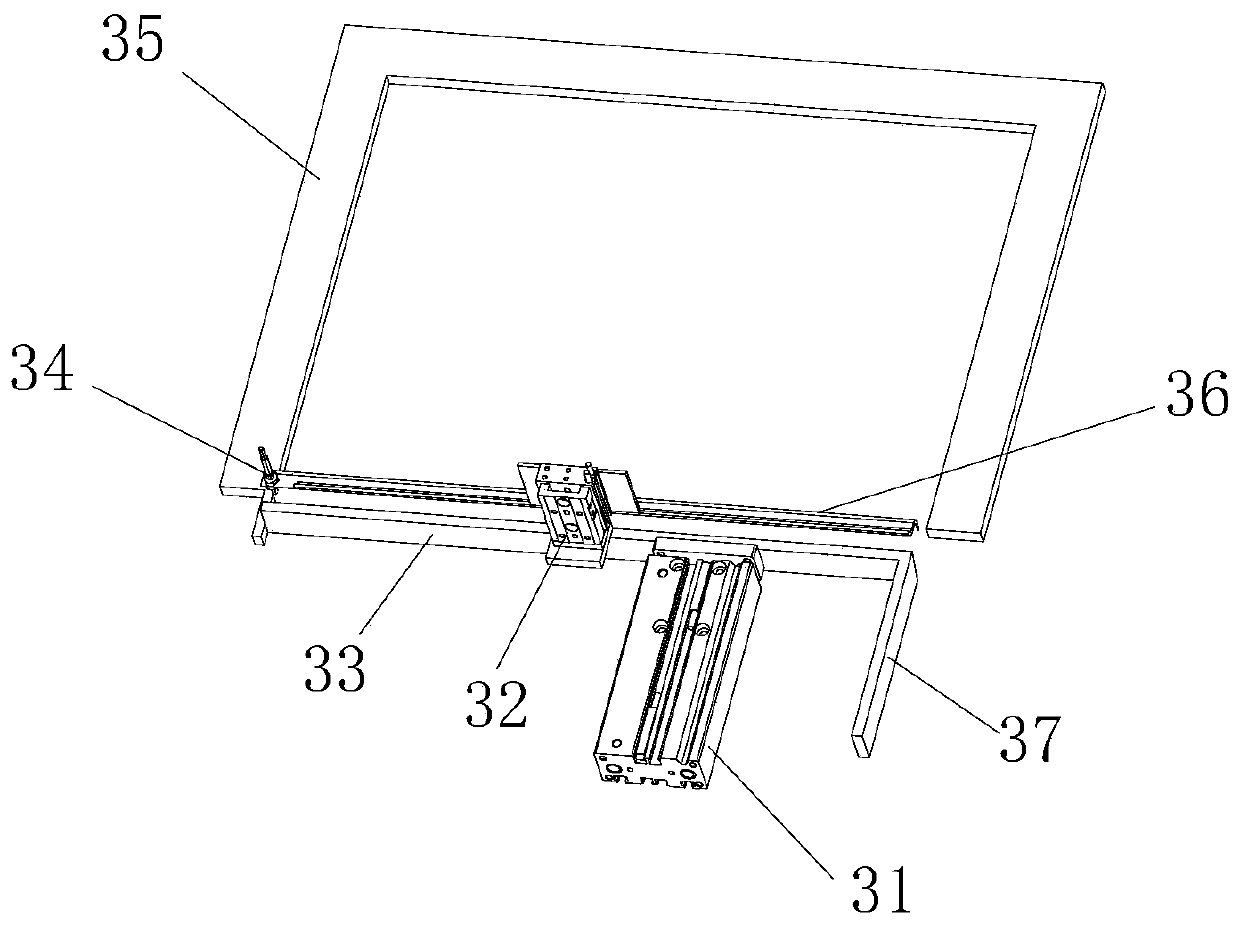

[0040] Further, the discharging mechanism 8 includes a vibrating disk 2 and a pushing mechanism 3, wherein the vibrating disk 2 and the pushing mechanism 3 are both installed above the frame...

Embodiment 2

[0055] The difference between this embodiment and the first embodiment is that a tray missing sensor 56 is connected to the bottom plate of the tray placing frame 51, and the tray missing sensor 56 is signally connected to the controller.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com