High-temperature-resistant low-thermal-conductivity heat-insulating wave-transmitting material and preparation method thereof

A low thermal conductivity, wave-transparent material technology, applied in ceramic products, other household appliances, applications, etc., can solve the problems of dielectric performance deterioration, mechanical properties that cannot meet engineering requirements, poor thermal shock resistance, etc., and achieve excellent dielectric properties. Excellent electrical properties, meeting the requirements of the working environment, and excellent thermal shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0035] According to a second aspect of the present invention, there is provided a method for preparing a high-temperature-resistant, low-thermal-conductivity, heat-insulating wave-transmitting material, which is used to prepare the high-temperature-resistant, low-thermal-conductivity, heat-insulating wave-transmitting material described in the first aspect, comprising the following steps:

[0036] Step 1, adding ceramic fiber, sintering aid and setting agent into water, stirring and dispersing to obtain fiber slurry, and the mass proportion of setting agent is 10% to 40% of the total mass of ceramic fiber;

[0037] Step 2, pouring the fiber slurry into the mold and dewatering through suction filtration to obtain a wet blank, and then pressurizing the wet blank to a set thickness;

[0038] Step 3, drying the wet blank to obtain a dry blank;

[0039] In step 4, high temperature sintering is performed on the dry blank to obtain a high temperature resistant and low thermal conduct...

Example Embodiment

[0046] Example 1

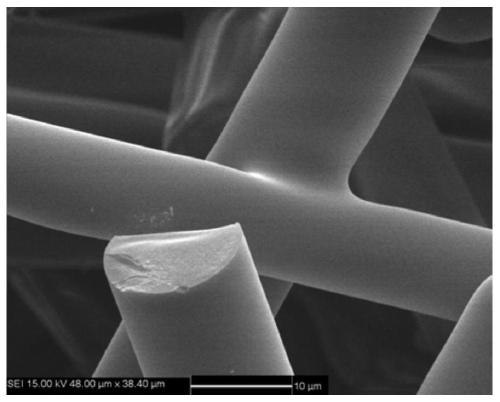

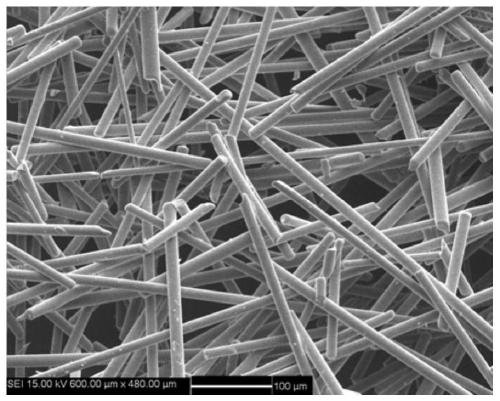

[0047] (1) According to the mass ratio m of silicon nitride chopped fibers, starch, boron nitride and water 氮化硅短切纤维 :m 淀粉 :m 氮化硼 :m 水 =1:0.2:0.03:40 ratio to prepare fiber slurry;

[0048] (2) Pour the fiber slurry into the mold and obtain a wet blank through suction filtration and dehydration, and then pressurize it on a pressure molding machine to a thickness of 30mm;

[0049] (3) drying the wet blank in an oven at 100°C for 12 h to obtain a dry blank;

[0050] (4) The dry blank is put into a high temperature furnace and sintered at 1200 ℃ for 1 h to obtain a high temperature resistant and low thermal conductivity heat-insulating wave-transmitting material.

[0051] After testing, the density of the above material is 0.24g / cm 3 , the thermal conductivity at room temperature is 0.042W / m·K, the compressive strength at 10% strain is 0.50MPa, and the dielectric constant and dielectric loss at room temperature are lower than 1.32 and 2×10 in the range o...

Example Embodiment

[0053] Example 2

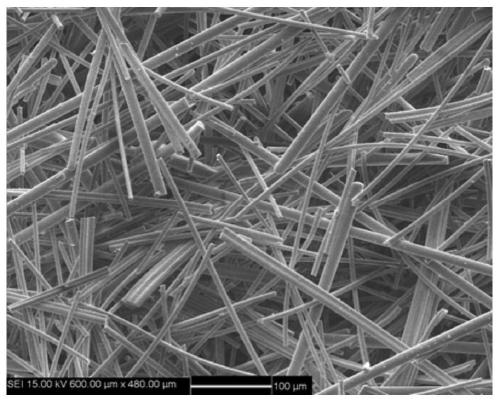

[0054] (1) According to the mass ratio m of silicon nitride chopped fibers, starch, boron nitride and water 氮化硅短切纤维 :m 淀粉 :m 氮化硼 :m 水 =1:0.3:0.03:25 ratio to prepare fiber slurry;

[0055] (2) Pour the fiber slurry into the mold and obtain a wet blank through suction filtration and dehydration, and then pressurize it on a pressure molding machine to a thickness of 30mm;

[0056] (3) drying the wet blank in an oven at 120°C for 8 hours to obtain a dry blank;

[0057] (4) The dry blank is put into a high temperature furnace and sintered at 1200° C. for 3 hours to obtain a high temperature and low thermal conductivity heat-insulating wave-transmitting material.

[0058] After testing, the density of the above material is 0.31g / cm 3 , the room temperature thermal conductivity is 0.049W / m K, the compressive strength at 10% strain is 0.80MPa, and the room temperature dielectric constant and dielectric loss are lower than 1.34 and 2.1×10 in the range of 7-4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Thermal conductivity at room temperature | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com