Ship lift safety mechanism gap adjusting device and adjusting method thereof

A gap adjustment device and safety mechanism technology, applied in the direction of ship lifting device, vertical lifting ship machinery, construction, etc., can solve the problems of narrow operating space, dangerous operation, and affecting the safety and efficiency of the gap adjustment of the safety mechanism of the ship lift, etc. Achieve the effect of meeting accuracy requirements and improving tuning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

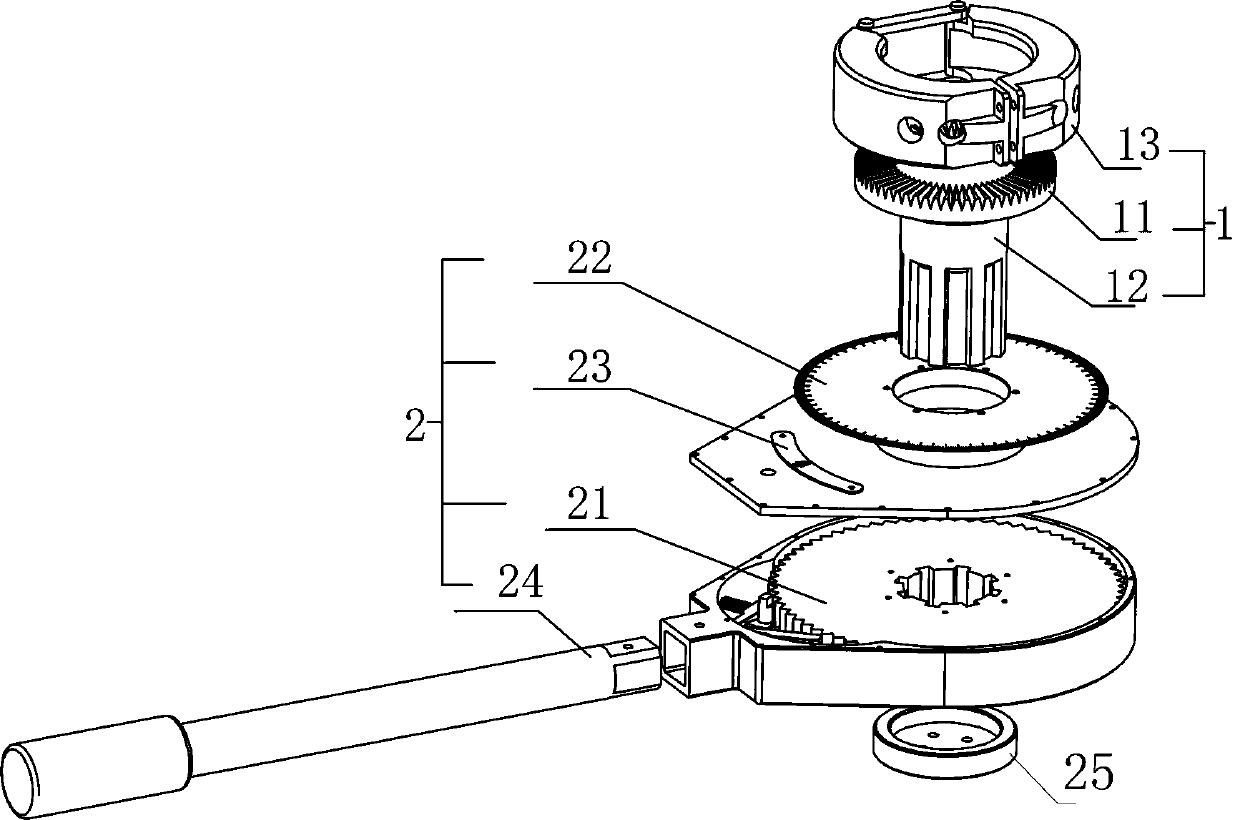

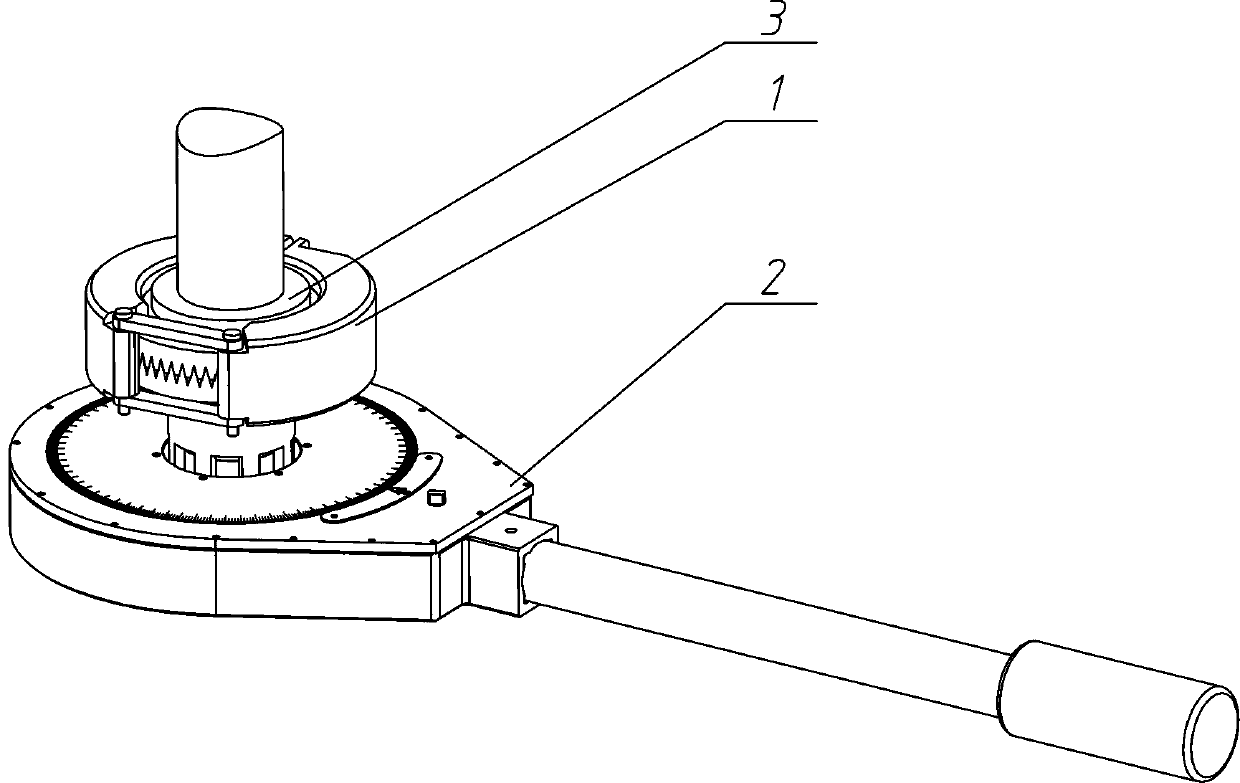

[0046] The preferred solution is as Figure 1 to Figure 4 As shown, a clearance adjustment device for a ship lift safety mechanism includes a shaft coupling 1 and a driving device 2. The shaft coupling 1 includes a lower swivel support disc 11, a connecting shaft 12 and a hoop 13. The lower swivel support disc 11 is connected to The shaft 12 is coaxially connected, and the hoop 13 is used to connect the lower revolving support disc 11 with the upper revolving support disc 3 of the drive shaft of the safety mechanism. The driving device 2 is used to drive the connecting shaft 12 to rotate, thereby rotating the upper revolving support disc 3 .

[0047] Further, as figure 2 As shown, the lower swivel support disc 11 is a ring structure with splines, and the ring structure with splines is used to engage with the spline ring structure of the upper swivel support disc 3 .

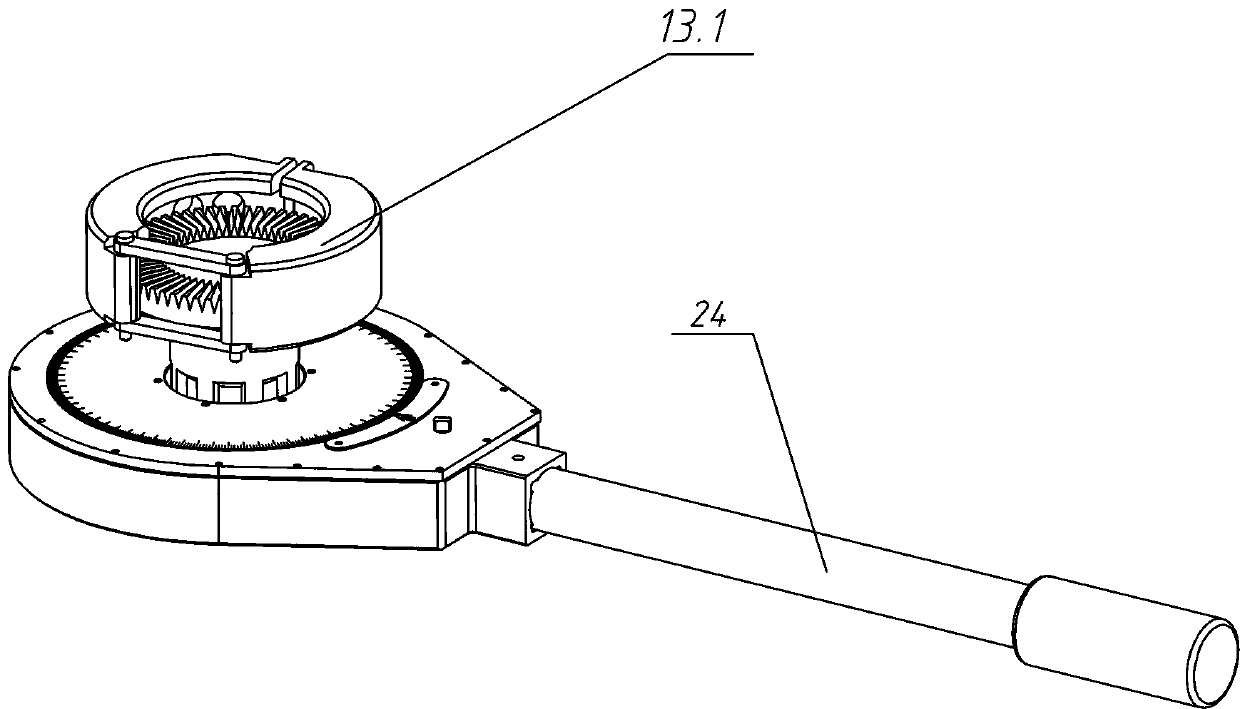

[0048] Further, as image 3 As shown, the hoop 13 includes two arc-shaped fixing groove plates 13.1, and t...

Embodiment 2

[0059] In a preferred solution, the method for adjusting the clearance of the safety mechanism of the ship lift includes the following steps:

[0060] Step 1), disconnect the connection between the drive point reducer and the synchronous shaft that needs to be adjusted, adjust the attitude of the ship to the level, and reinstall the synchronous shaft;

[0061] Step 2), respectively measuring the upper clearance of the threaded pair of the safety mechanism and the lower clearance of the threaded pair of the safety mechanism to determine the adjustment direction of the clearance;

[0062] Step 3), remove the universal coupling driven by the safety mechanism, engage the lower rotary support plate 11 of the safety mechanism turning device with the upper rotary support plate 3 in alignment, and use the hoop 13 to connect the lower rotary support plate 11 and the upper rotary support plate 3 clamping;

[0063] Step 4), use the device to rotate the safety mechanism clockwise or coun...

Embodiment 3

[0068] Such as Figure 5 to Figure 7 As shown, the long nut-short screw type safety mechanism is a type of safety guarantee mechanism of the ship lift. During the lifting process of the cabin, the rotating screw goes up and down synchronously with the pinion of the driving mechanism. Contact, there is a certain gap between the two in the upper and lower directions during installation, that is, there is an upper gap between the safety mechanism thread pair and a lower gap between the safety mechanism thread pair. The full balance of the ship’s cabin is destroyed, which causes the gap between the screw threads of the safety mechanism to become smaller until the gap disappears completely, and the unbalanced load of the ship’s box is transmitted to the nut column through the screw rod, so as to prevent disasters caused when the full balance of the ship lift is destroyed sex accident.

[0069] The currently known safety mechanism installation methods are mainly aimed at the constru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com