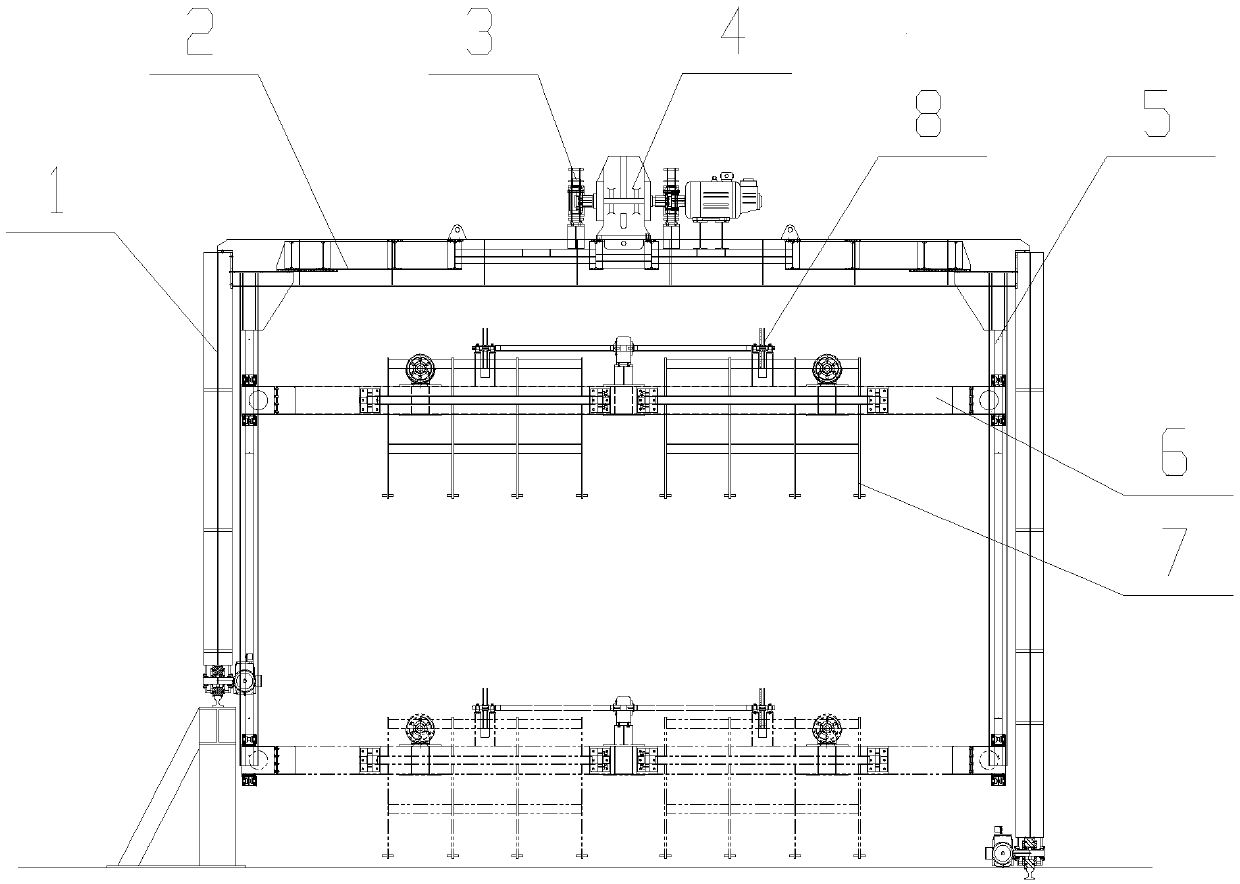

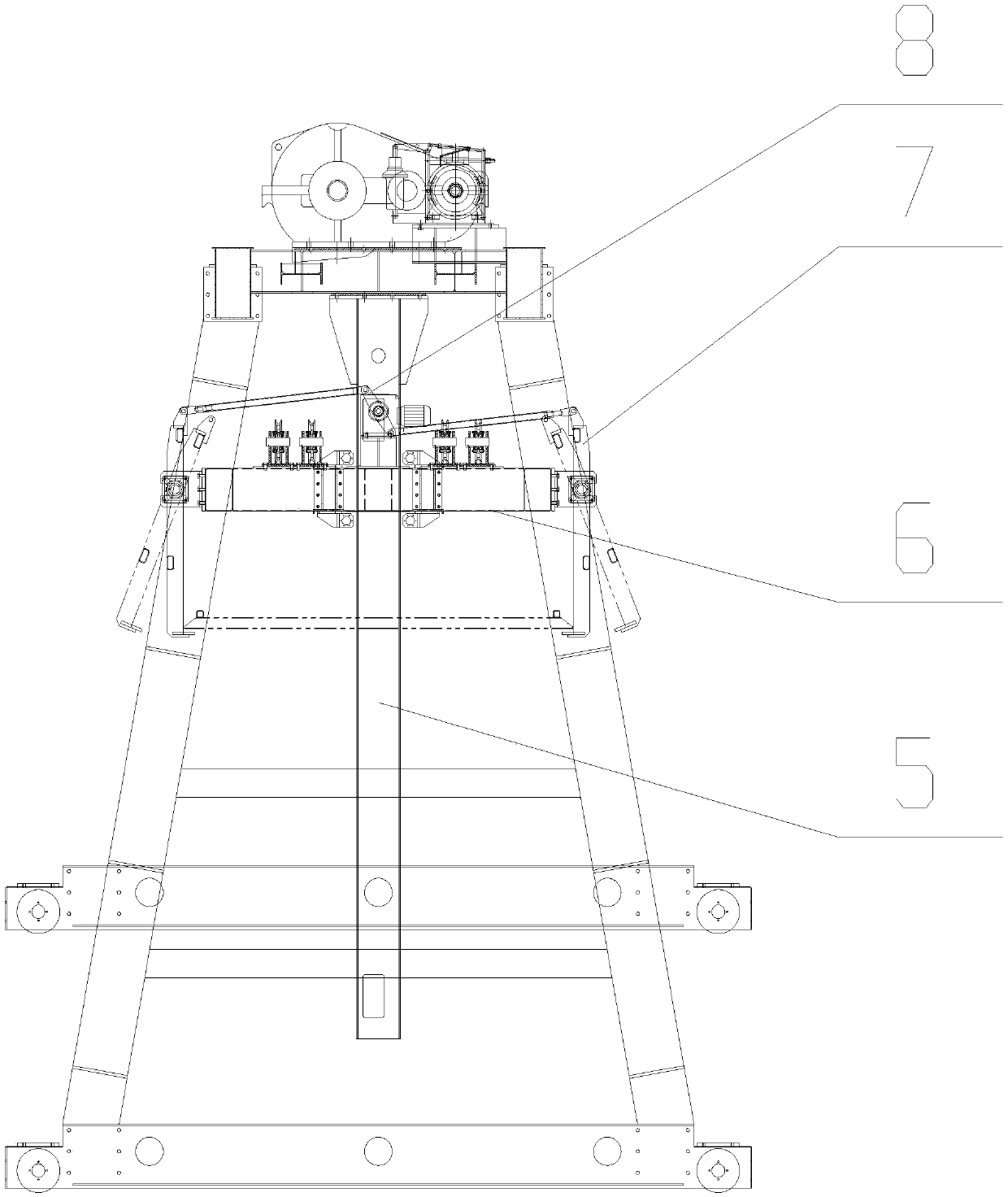

Portal type aluminium bar stacking and unstacking unit

A gantry type and stacking technology, applied in the field of gantry type aluminum bar stacking and depalletizing units, can solve the problems of inconvenient maintenance of the stacking unit, affecting the overall aesthetics of the workshop, affecting the layout of the stacking units, etc. Manual operation and maintenance, easy maintenance of mechanical equipment, good economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1. The lifting control device mainly has a fairly complete detection and control logic relationship in electricity. The normal lifting height position is different every time. According to the actual working state, the system calculates the height position that needs to be reached in the next step. The calculation record data of this position is given by the encoder; but in order to prevent the encoder from malfunctioning , and added laser ranging to verify the actual position information that should be reached; if the information given by the two exceeds the set value, the lifting control device will alarm, and the braking equipment is waiting for manual maintenance. The communication completes the transmission;

[0030] An infrared detection obstacle is installed under the traveling mechanism to prevent the gantry frame from colliding with sundries and personnel; when the obstacle is removed, the electronic control system will automatically start after 5 se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com