Built-in balance container

A balance container, built-in technology, used in the display of liquid level indicators, components of steam boilers, steam boiler accessories, etc. through pressure measurement, which can solve the problems of vaporization, inability to accurately measure the water level of boiler drums, and hidden dangers in production safety, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

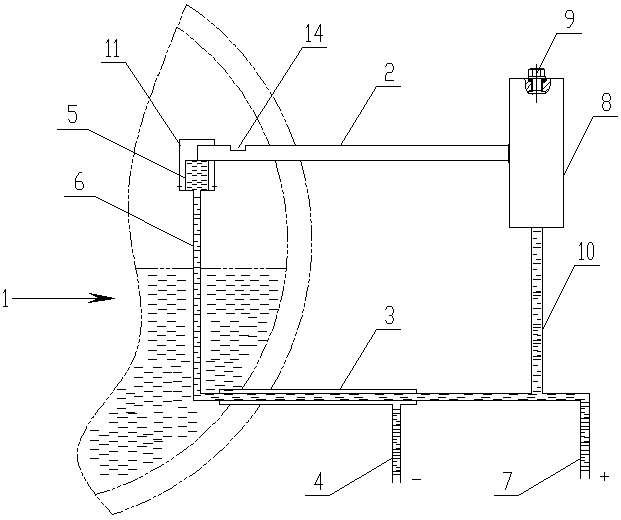

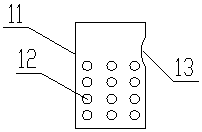

[0014] See figure 1 , figure 2 , The present invention is a built-in balance vessel for measuring the water level of the boiler steam drum 1. It includes a steam connecting pipe 2 extending horizontally to the upper part of the boiler drum and a water connecting pipe 3 extending horizontally to the lower part of the boiler steam drum. The water connecting pipe on the outside of the bag is connected with a negative pressure conduit 4, and it also includes a reference cup 5 arranged in the boiler drum 1. The bottom of the reference cup has a reference pipe 6, and the bottom end of the reference pipe 6 is bent by the water The horizontal seal in the connecting pipe 3 extends to the outside of the water connecting pipe, and the reference pipe extending to the outside of the water connecting pipe is connected with a positive pressure conduit 7, and the reference cup 5 is located at the front of the nozzle of the steam connecting pipe in the boiler drum. Below, the water connecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com