Anti-dripping bottle cap and anti-dripping method thereof

An anti-drip and bottle cap technology, which is applied in the field of seasoning packaging, can solve problems such as the liquid discharge and liquid collection are not smooth enough, oil droplets adhere to the fixed boss, and parabolic interference is prone to occur, so as to avoid oil leakage or dripping Oil phenomenon, reduce pollution or oil leakage, improve the effect of user experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

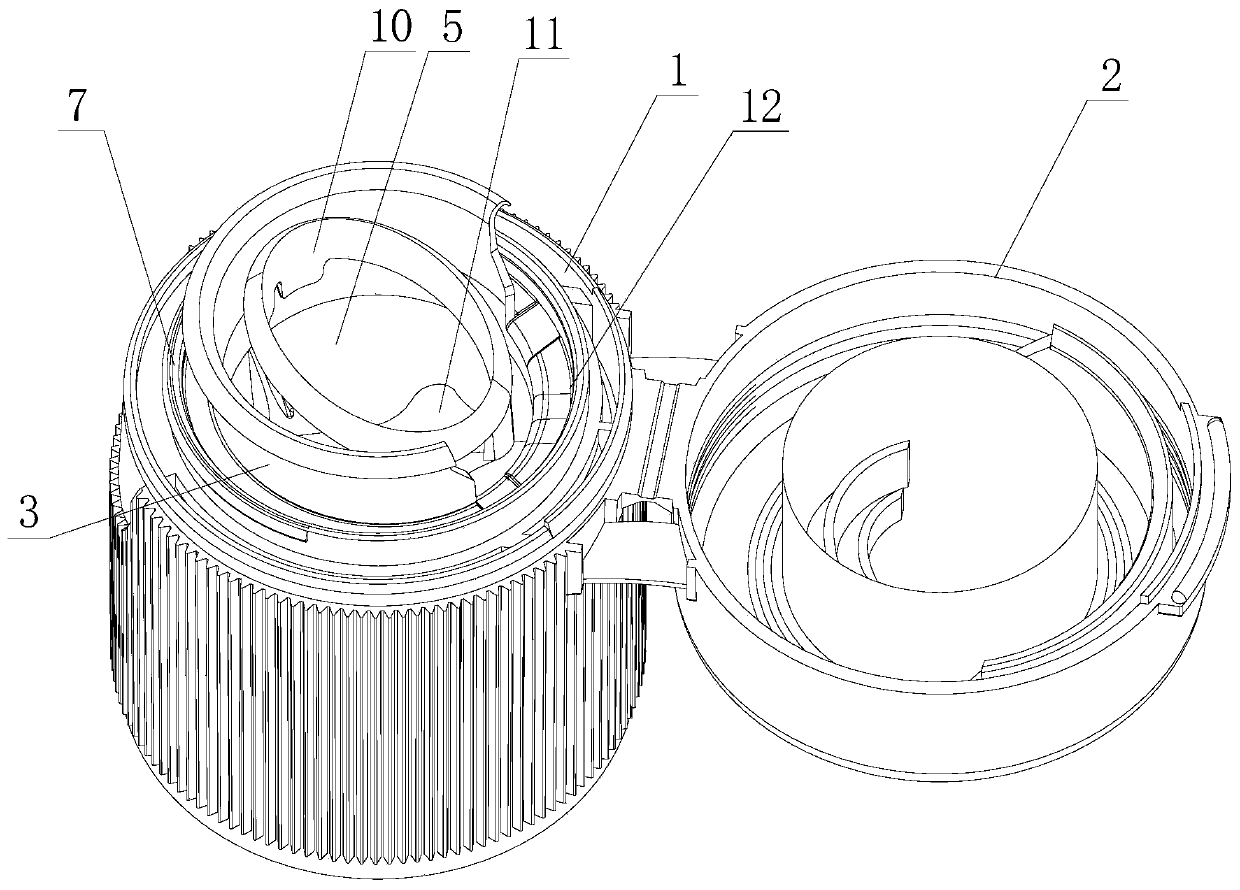

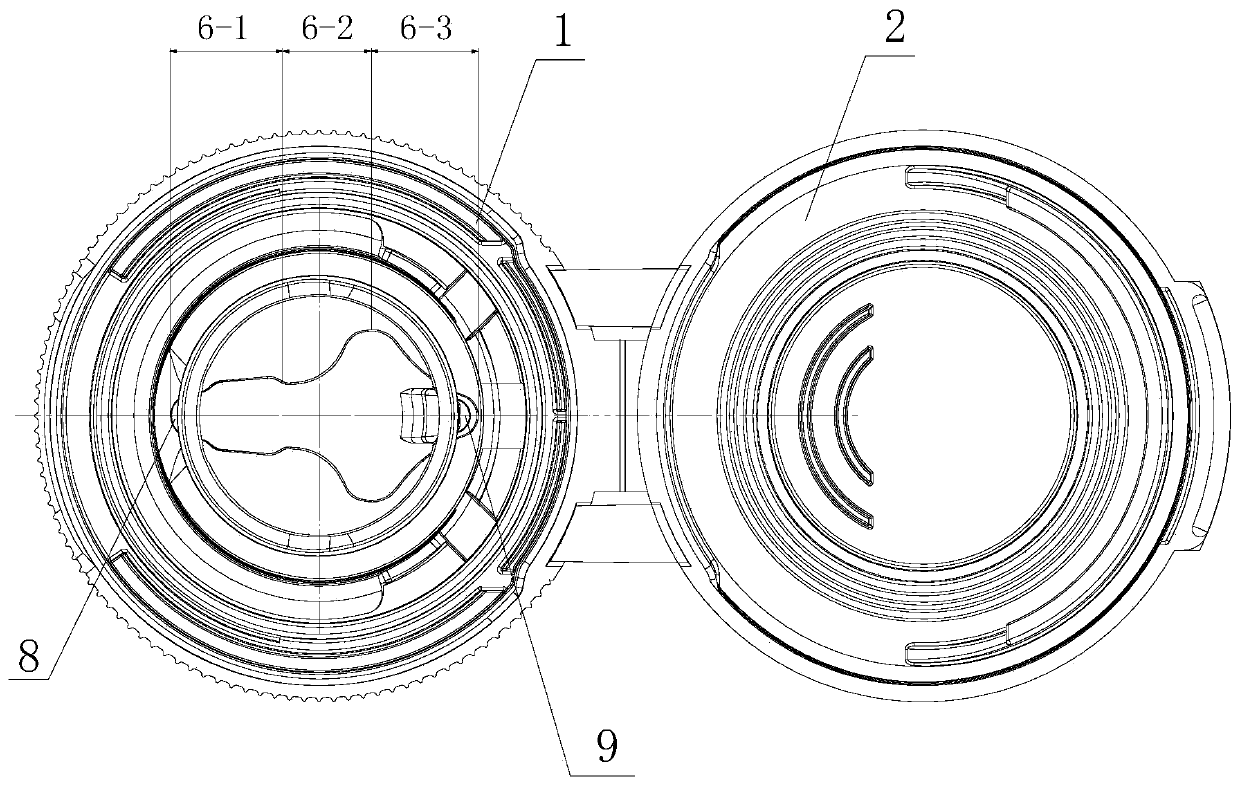

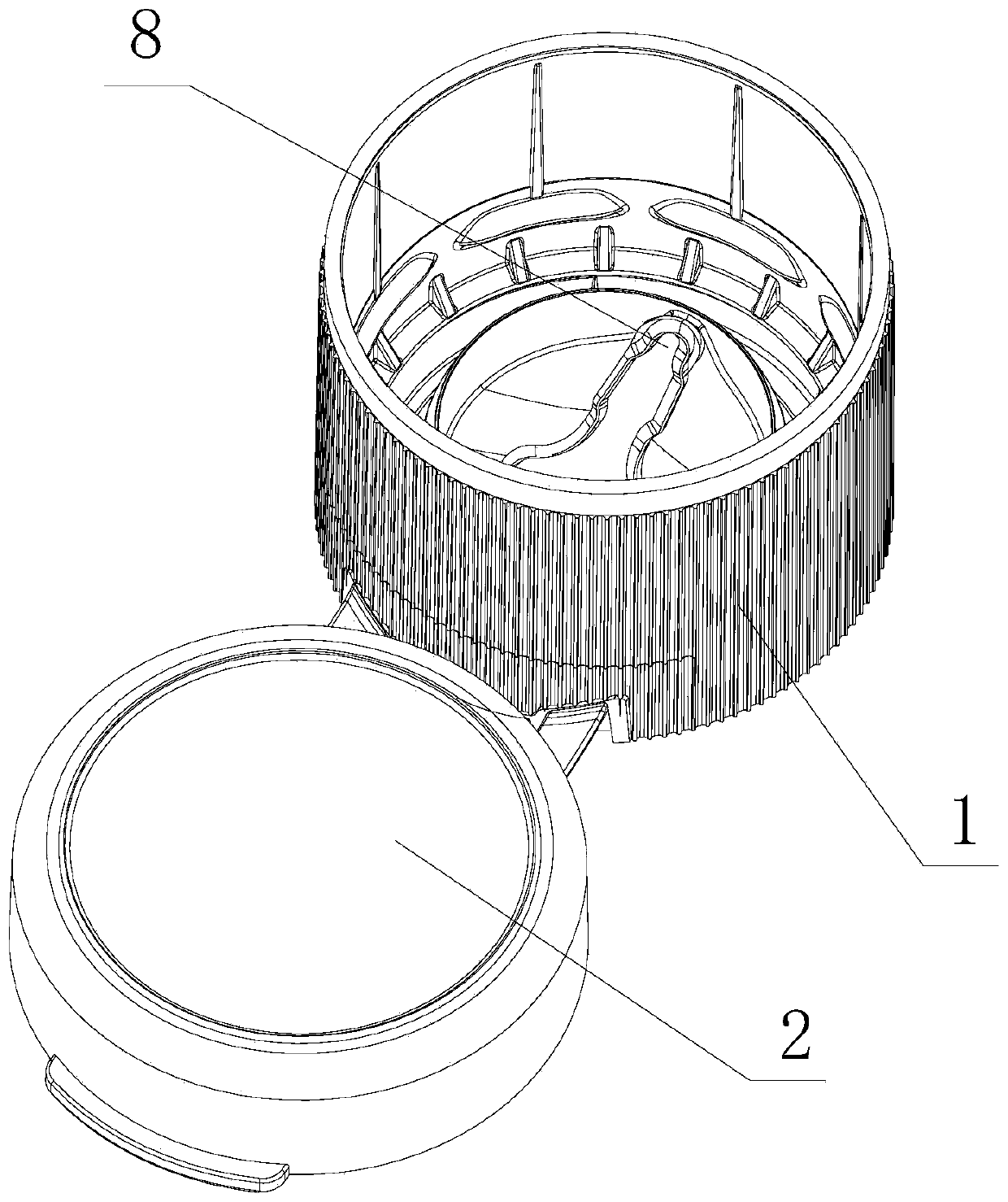

[0040] A kind of anti-drip bottle cap of the present embodiment, as figure 1 As shown, it includes the connected cover body 1 and upper cover 2, such as Figure 4 As shown, the middle part of the cover body is provided with a diversion tube 3, and the upper part of the diversion tube is a diversion nozzle 4, and the diversion nozzle is arranged obliquely; Connection, as shown in Figure 6, an opening 6 is provided in the middle of the return flow part, and one end of the opening is located below the diversion nozzle. In this structure, by changing the structural form of the diversion nozzle, its inclined structure is used to improve the smoothness of liquid discharge and liquid collection when pouring oil, thereby effectively avoiding oil dripping or oil leakage.

[0041] Among them, such as Figure 5 As shown, the inclination angle of the diversion nozzle is about 4°, that is to say, an angle of about 4° is formed between the inner wall of the diversion nozzle and the axis o...

Embodiment 2

[0049] This embodiment is a kind of anti-drip bottle cap. Compared with Embodiment 1, its difference is that: in the cap body, the outer periphery of the guide tube is provided with a fixed boss 7, such as Figure 5 As shown, the distance L between the top of the diversion nozzle and the top surface of the fixed boss is 4-8 mm. In this embodiment, by adjusting the distance between the top of the diversion nozzle and the top surface of the fixed boss, the liquid can form a good parabolic trajectory when pouring oil, avoiding interference from the fixed boss, which is conducive to increasing the oil output speed , At the same time, it can also avoid the phenomenon that oil droplets adhere to the fixed boss.

[0050] When this anti-drip bottle cap is used, its principle is: mainly use the inclined setting of the diversion nozzle to make the trajectory of the product form a good and smooth curve when pouring out, thereby improving the smoothness of liquid discharge and liquid coll...

Embodiment 3

[0052] This embodiment is a kind of anti-drip bottle cap. Compared with Embodiment 1, the difference is that: in the cover body, the outer periphery of the guide tube is also provided with an outer return boss 12, and the space inside the outer return boss is connected to the return flow. connected. The design of the external return boss is added. Even if the cover body of the above structure leaks, the oil drop can fall back into the return part by using the outer return boss, which is beneficial to the return of the accumulated liquid and further ensures that the oil drop will not leak outward.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com