Capillary core structure and preparation method thereof

A capillary core and microporous structure technology, applied in lighting and heating equipment, indirect heat exchangers, etc., can solve the problems of few vaporization core sites, low heat transfer power of heat pipes, poor capillary performance, etc., and achieve a simple and efficient preparation method. , Enhance the effect of nucleate boiling and good shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

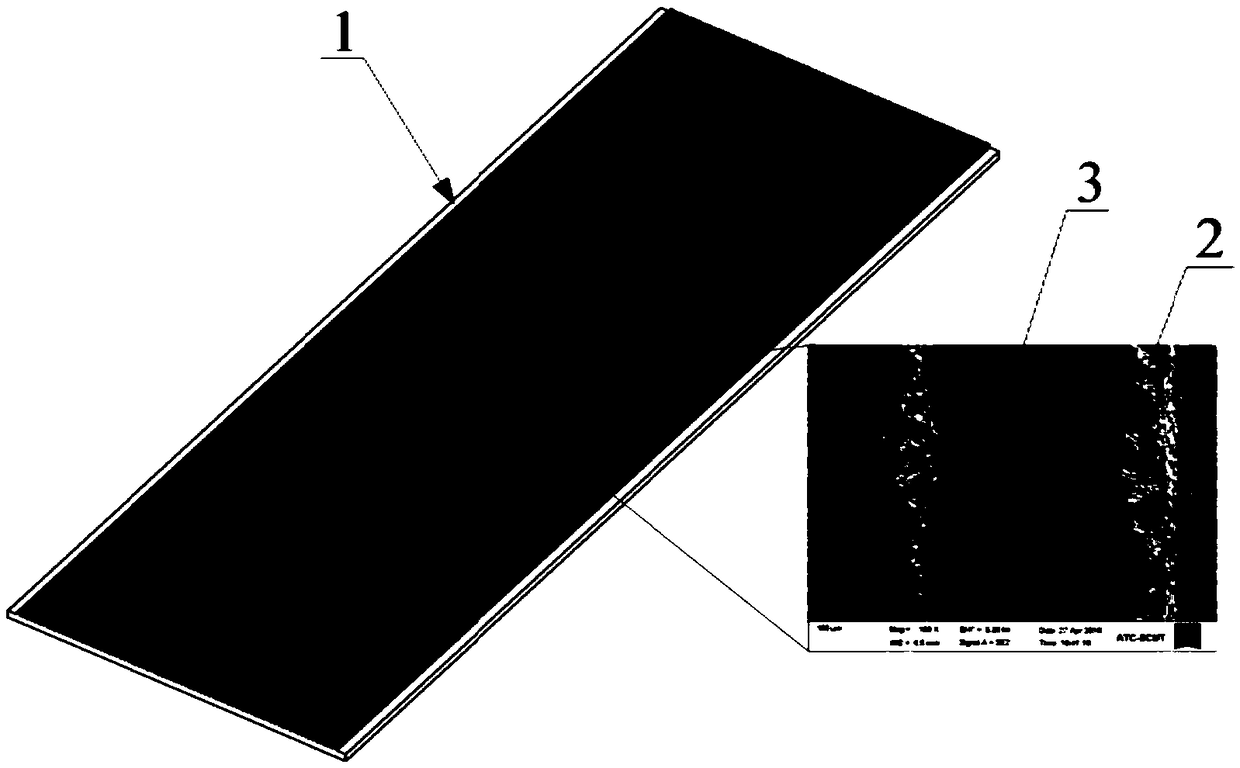

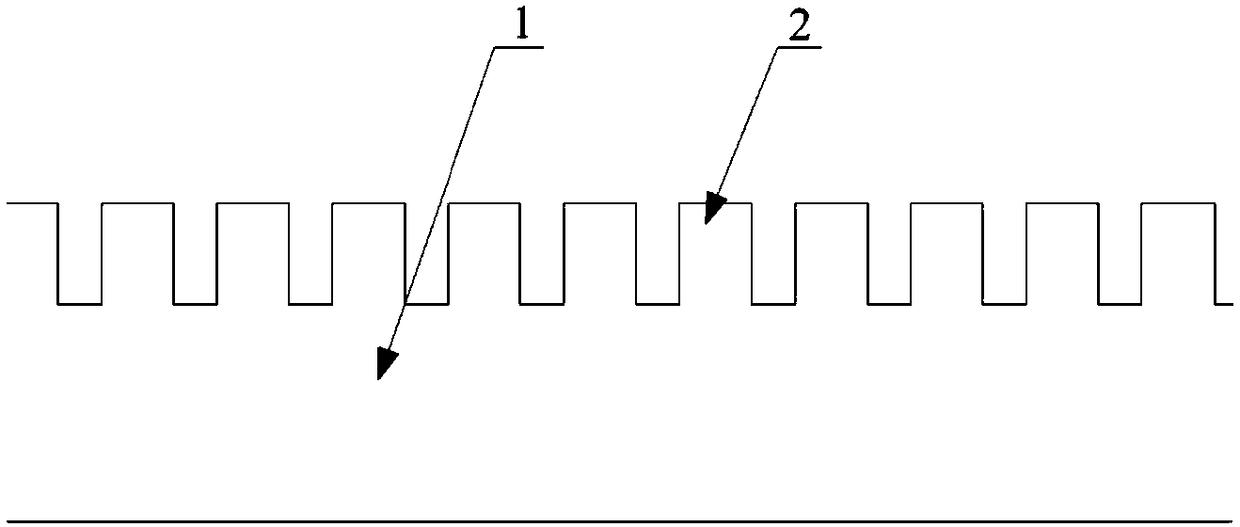

[0030] Such as Figure 1-2 As shown, a capillary core structure includes a copper substrate 1, on which a groove structure 2 arranged in parallel is arranged, and countless randomly distributed micropores 3 are formed on the surface of the groove structure. The groove depth is 0.3mm, the groove width is 0.2mm, the groove spacing is 0.5mm, and the equivalent diameter of micropores on the groove surface is 10-30μm.

[0031] The invention makes the groove also have a porous structure, and the pores are directly formed on the surface of the groove, which has stronger vibration resistance compared with sintering, and stronger capillary performance than pure grooves.

[0032] The manufacturing method of the above-mentioned capillary core structure comprises the following steps:

[0033] S1. Process a groove structure arranged in parallel on the surface of the copper substrate by wire cutting, and clean and dry it;

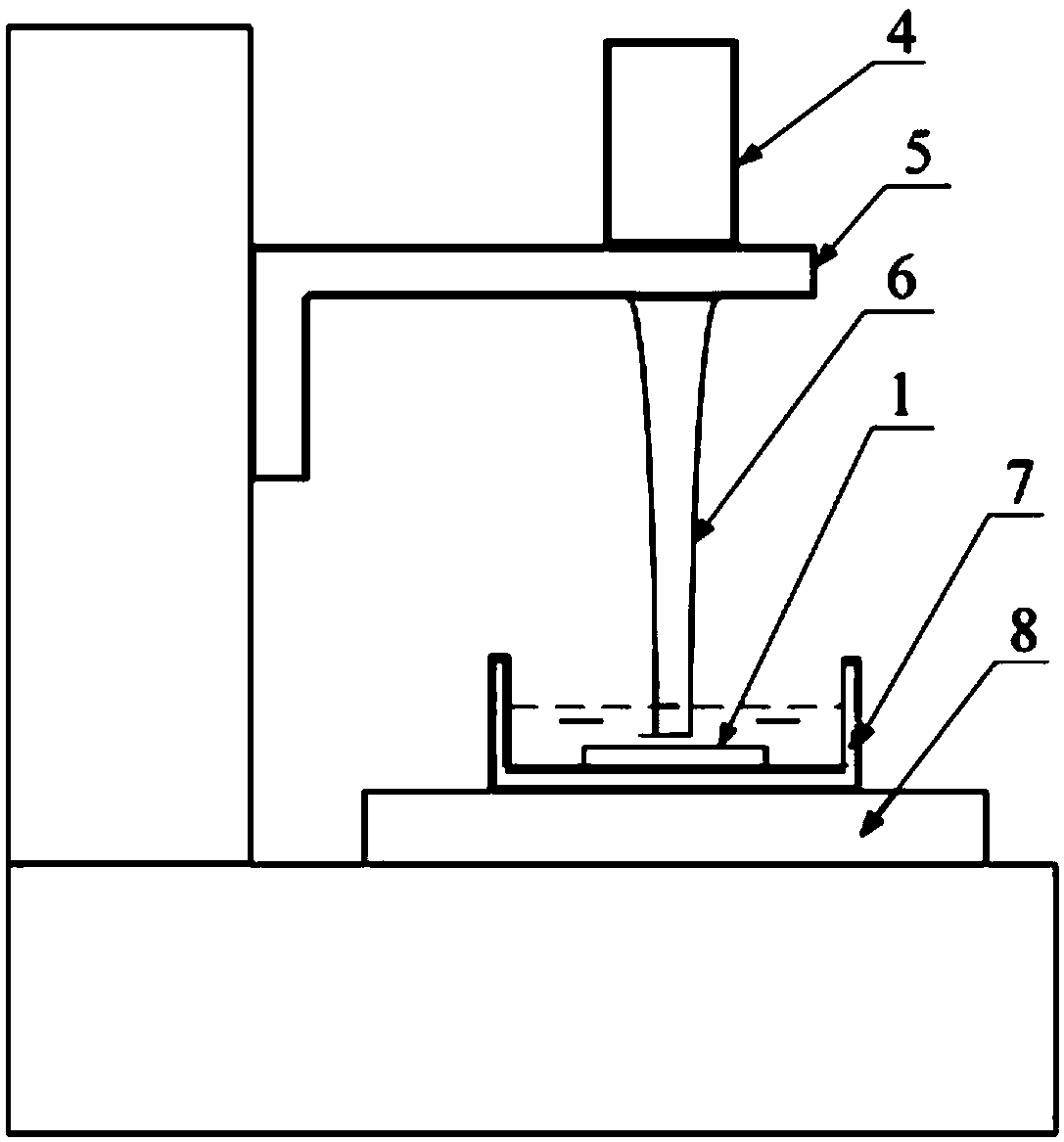

[0034] S2. Fix the processed red copper substrate on the bottom o...

Embodiment 2

[0037] A porous groove capillary core structure includes an aluminum base plate, on which a groove structure arranged in parallel is arranged, and countless randomly distributed micropores are formed on the surface of the groove structure. The groove depth is 0.7mm, the groove width is 0.5mm, the groove spacing is 0.7mm, and the equivalent diameter of micropores on the groove surface is 10-30μm.

[0038] The manufacturing method of the above-mentioned porous groove capillary core structure includes the following steps:

[0039] S1. Process a groove structure arranged in parallel on the surface of the aluminum substrate by milling, and clean and dry it;

[0040] S2. Fix the processed aluminum substrate on the bottom of the container containing pure water, the groove structure faces upward and the liquid level of the pure water is higher than the top surface of the groove, and the distance between the liquid surface of the pure water and the top surface of the groove is 15mm;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com