Blast furnace hot blast stove gas pipe network coordinated furnace changing method

A technology of gas pipe network and hot blast stove, which is applied to blast furnaces, blast furnace details, blast furnace parts, etc., can solve problems such as manpower management costs and untimely communication, uncertain blast furnace status, and non-prospective furnace replacement operations, etc., to achieve relief Effects of pressure fluctuations in the gas pipeline network, reduction of pressure fluctuations, and reduction of overlapping furnace replacement time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

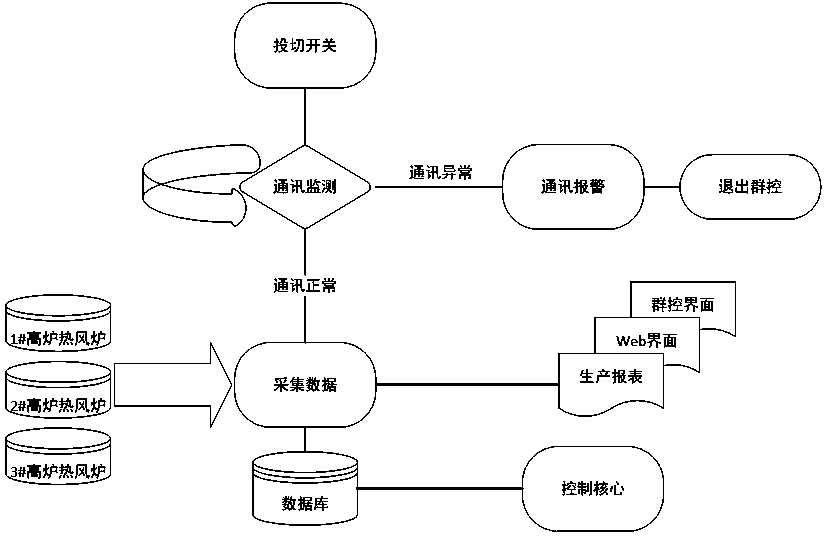

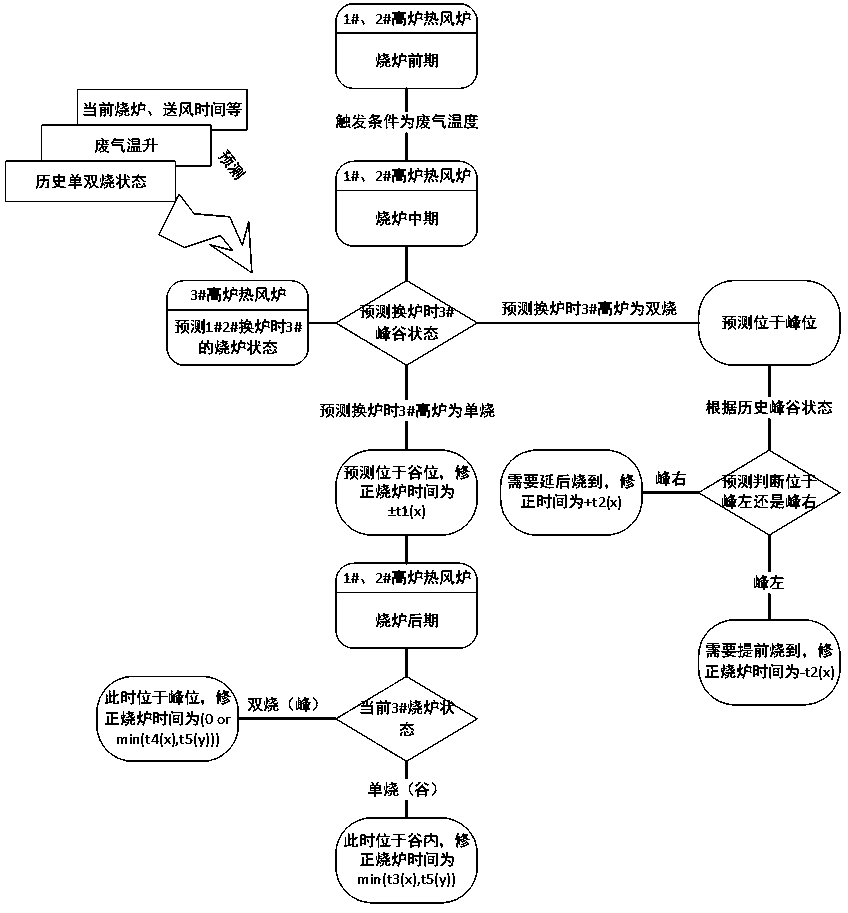

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

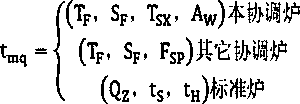

[0019] Taking a blast furnace hot blast stove site as an example, 3# is a 3200m³ blast furnace hot blast stove with two firings and two delivery, 1# and 2# are 1880m³ blast furnace hot blast stove with one firing, one braising and one delivery, and the comparison of the firing time of the 3# blast furnace hot blast stove The fixed time is about 90 minutes, the furnace replacement time (single firing time) is about 30 minutes, and the air supply time is about 120 minutes. 1# and 2# blast furnace hot blast stoves are fired according to the exhaust gas temperature, and the exhaust gas is burned to between 375°C and 395°C. For intermittent furnace replacement, the basic firing time is between 55 minutes and 65 minutes. Due to the firing mode of one firing, one stewing and one delivery, the furnace replacement time (double firing time) is between 1 minute a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com