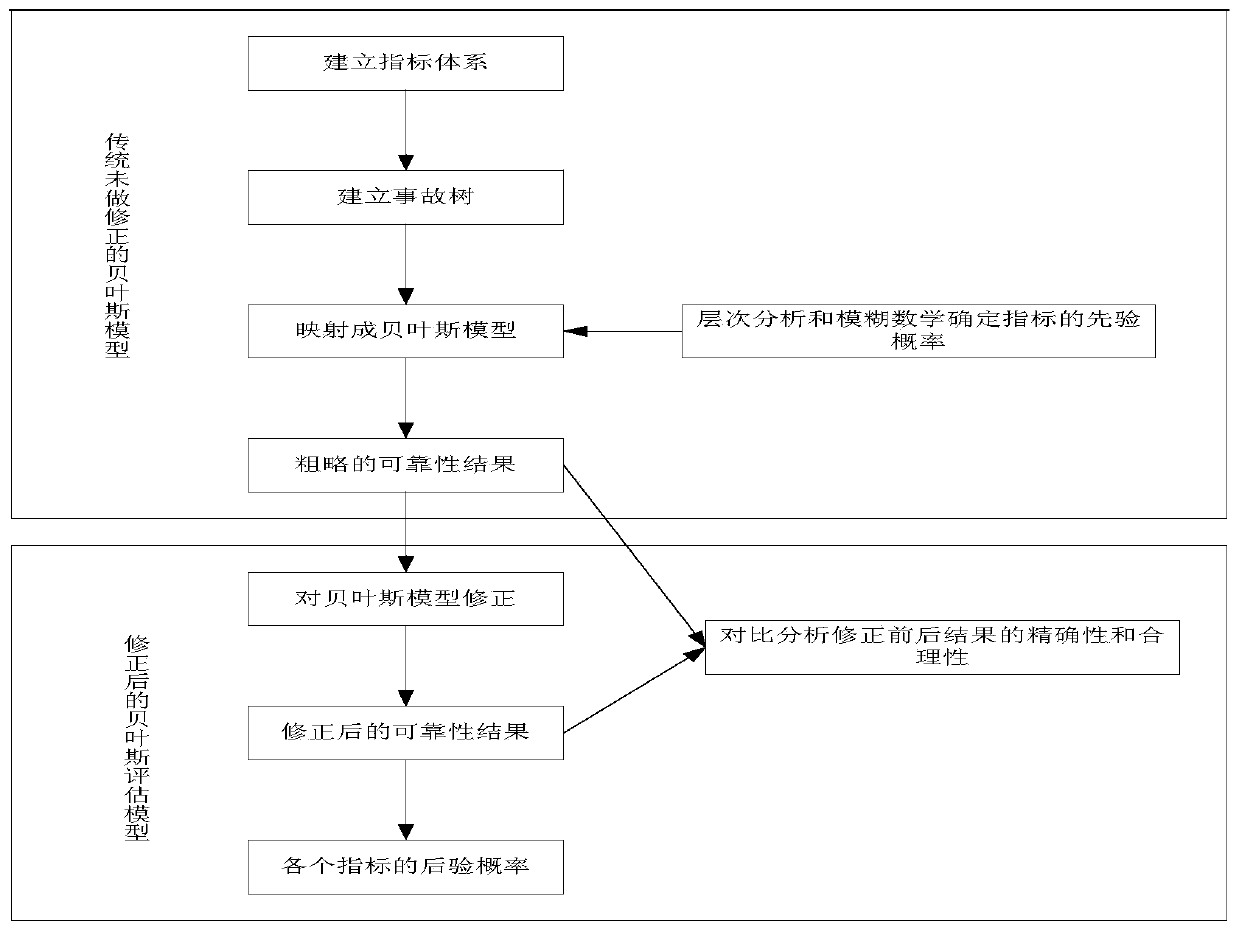

Pressure gauge calibration table reliability evaluation method based on Bayesian correction model

A technology of Bayesian model and model correction, which is applied in the fields of instrumentation, design optimization/simulation, electrical digital data processing, etc., and can solve problems such as gas leakage, oil leakage, fire or explosion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

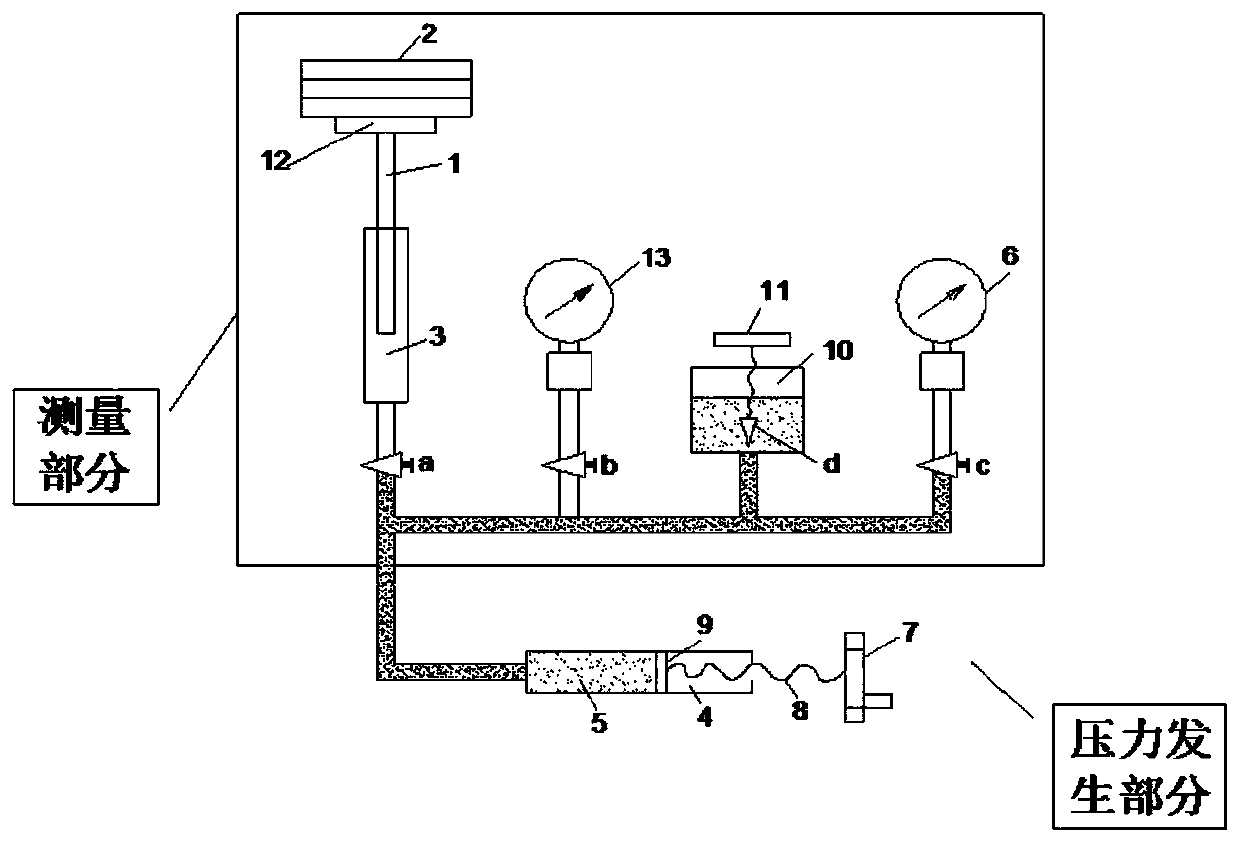

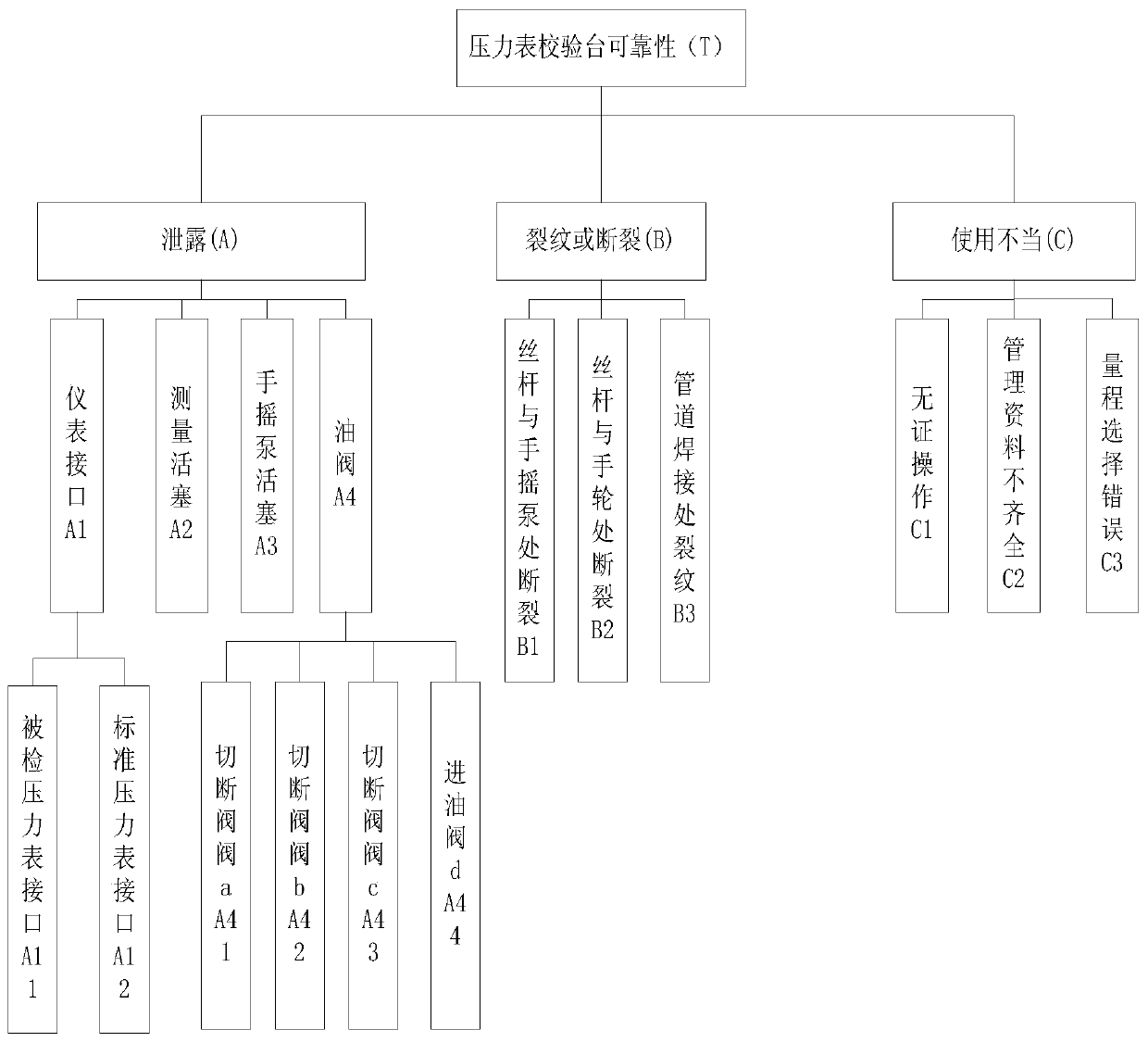

[0064] according to figure 2 The schematic diagram of the structure of the pressure gauge calibration table is shown, and the index system that can characterize the fault characteristics of the pressure gauge is established, and the structure of the pressure gauge calibration table is analyzed. It is mainly divided into a measurement part and a pressure generation part. The measurement part includes: ①Measuring piston ;②weight;③piston rod;④pressure gauge to be calibrated;⑤oil cup;⑥handwheel of oil inlet valve;

[0065] The pressure generation part mainly includes: ①working fluid; ②hand pump; ③hand pump piston; ④screw; ⑤hand wheel; ⑥pipeline.

[0066] The analysis of these components combined ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com