Dyeing scheduling equipment, production card number input method and storage medium

A storage medium and scheduling technology, applied in the direction of sensing record carriers, resources, instruments, etc., can solve problems such as error-prone and high labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

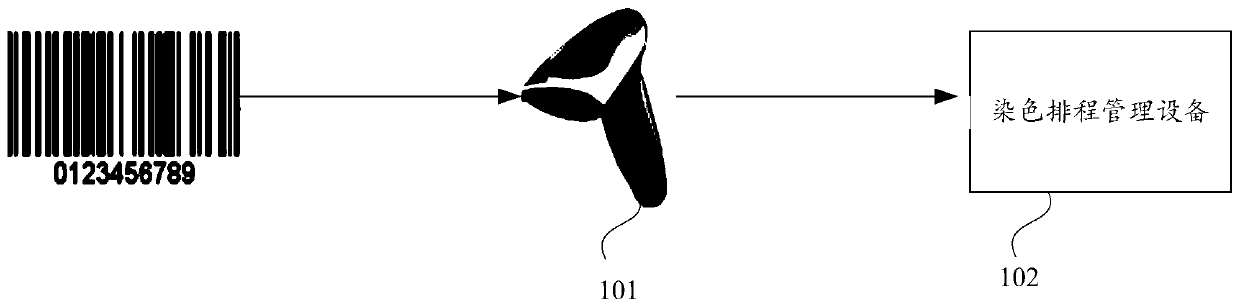

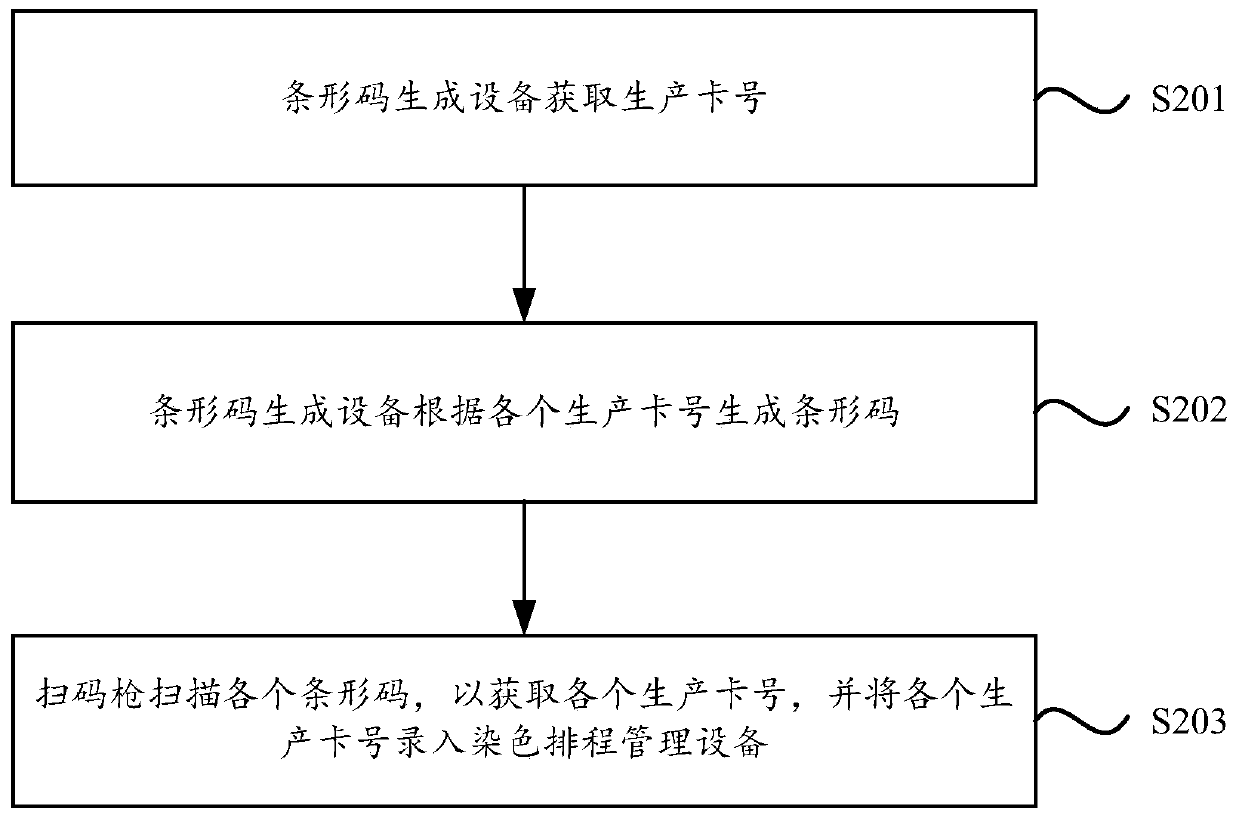

[0036] figure 1 It is a schematic structural diagram of a dyeing scheduling device provided by an embodiment of the present invention. refer to figure 1 , the dyeing scheduling device may specifically include a code scanning gun 101 and a dyeing schedule management device 102 .

[0037] Wherein, the code scanning gun 101 is used to scan the barcode generated according to each production card number to obtain the production card number represented by the barcode, and send each production card number to the dyeing schedule management device; the dyeing schedule management device 102 receives each production card number, Create a new schedule based on each production card number.

[0038] Specifically, a barcode gun is a barcode scanner, also known as a barcode reader, a barcode scanner, a barcode scanner, a barcode scanner and a barcode reader. Optionally, after the barcode is generated, the barcode is displayed on the barcode generating device, or presented in paper form. F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com