Toy building element made of a polymeric pet material

A technology of toy building elements, polymer materials, applied in the field of manufacturing such toy building elements, capable of solving problems such as unsatisfactory stability and impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

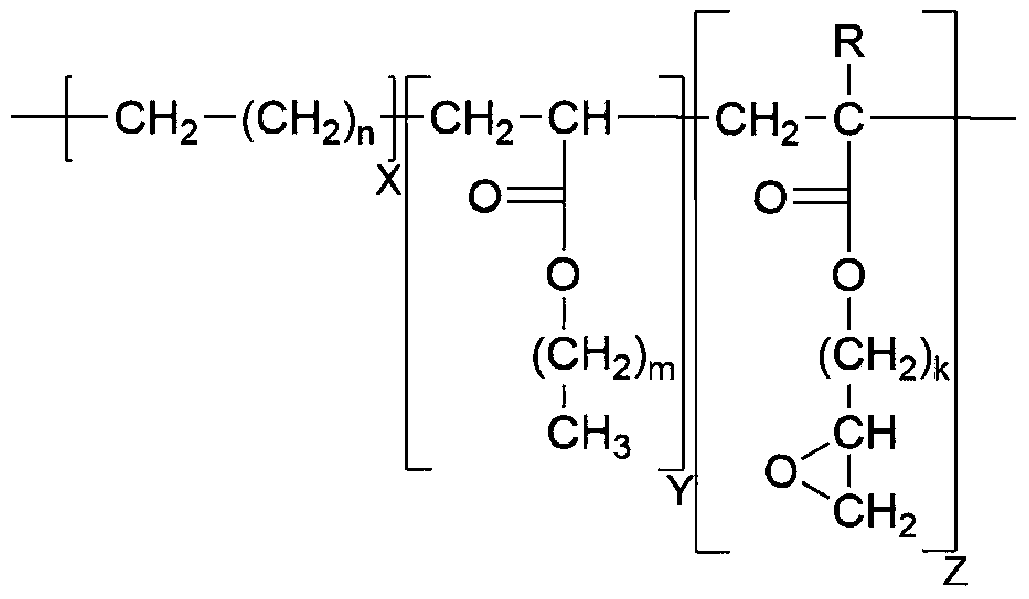

Method used

Image

Examples

Embodiment 1

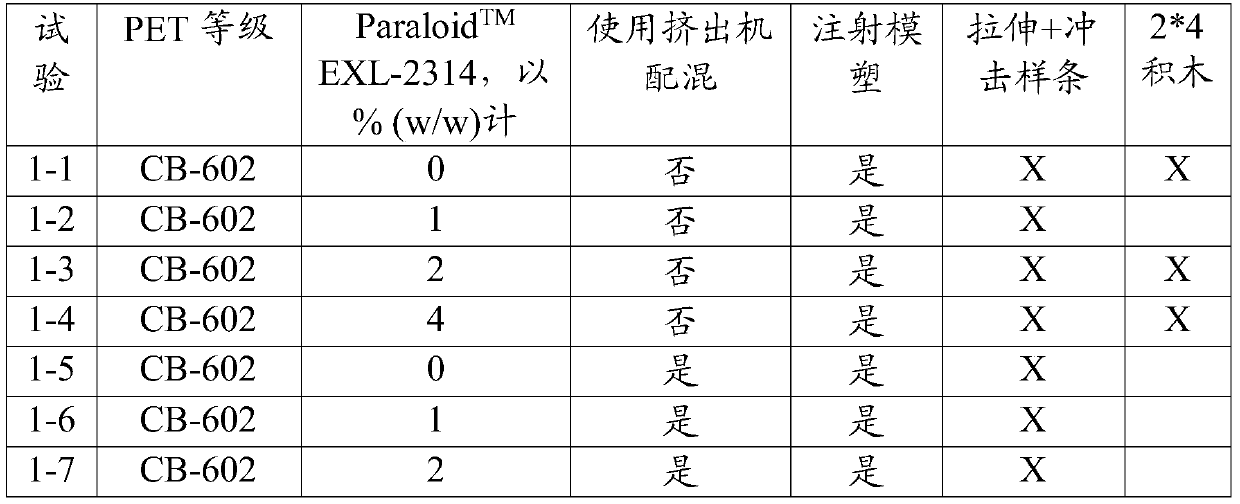

[0136] Example 1. Using PET with Paraloid TM EXL-2314 modified

[0137] Bottle grade PET CB-602 (supplied by Far Eastern New Century (FENC)) with an IV of 0.80 dl / g was dried at 150 degrees Celsius to a moisture content of 50-100 ppm. When the dried PET material is ambient cooled to below 50 degrees Celsius, the PET is mixed with the impact modifier Paraloid TM EXM-2314 (acrylic copolymer from Dow Chemical Company) was dry blended in the amounts mentioned in the table below. The blends were processed directly via injection molding (Arburg, Allrounder 470 E 1000-400, 30 mm screw, Germany) or via extrusion (twin screw, Labtech Engineering Company Ltd, Thailand) followed by injection molding.

[0138]

[0139] The injection molding parameters were as follows:

[0140] Melt temperature: 295 degrees Celsius

[0141] Hot runner temperature: 300 degrees Celsius

[0142] Mold temperature: 20 degrees Celsius

[0143] The extrusion processing parameters are as follows:

[0144...

Embodiment 2

[0151] Example 2. Substituting PET and recycled PET (rPET) with ethylene-glycidyl methacrylate copolymer (E-GMA) AX8700 and AX8900 modification

[0152] Bottle grade PET CB-602 (supplied by Far Eastern New Century (FENC)) with an IV of 0.80 dl / g and commercial grade post-consumer rPET CB-602R (supplied by FENC) with an IV of 0.82 dl / g were tested at 150 Dry to a moisture content of 50-100ppm at °C. When the dried PET samples were ambient cooled to below 50 degrees Celsius, the samples were mixed with AX8700 (supplied by Arkema) which is a reactive random terpolymer of ethylene, butyl acrylate and glycidyl methacrylate (epoxy functional)), or AX8900 (supplied by Arkema), which is a reactive random terpolymer (epoxy functional) of ethylene, methyl acrylate and glycidyl methacrylate, was dry blended in the amounts mentioned in the table below and Processed by injection molding (Arburg, Allrounder 470E 1000-400, 30 mm screw, Germany).

[0153] test PET grade ...

Embodiment 3

[0163] Example 3. Modification of different PET grades with various impact modifiers

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com