Shunt resistor

A technology of shunt resistors and resistors, applied in the direction of resistors, resistor parts, non-adjustable metal resistors, etc., can solve the problem that the base metal cannot obtain sufficient joint strength, and achieve strong welding, improved load-bearing capacity, and easy dissolution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] An embodiment of the shunt resistor of the present invention will be specifically described below with reference to the drawings. In addition, in the following description, when showing the up, down, left, and right directions, the up, down, left, and right sides when viewed from the front of the illustrations shall prevail.

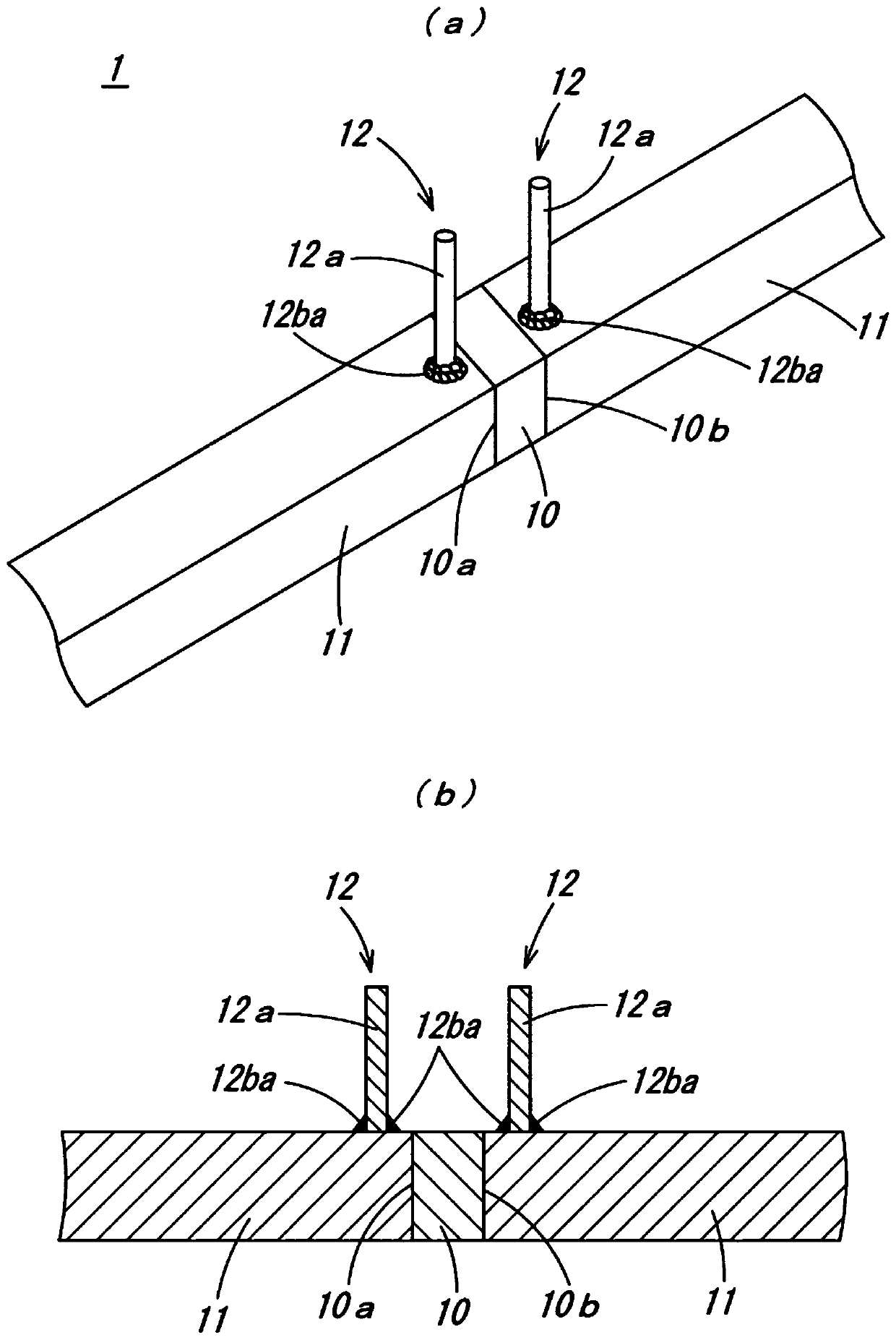

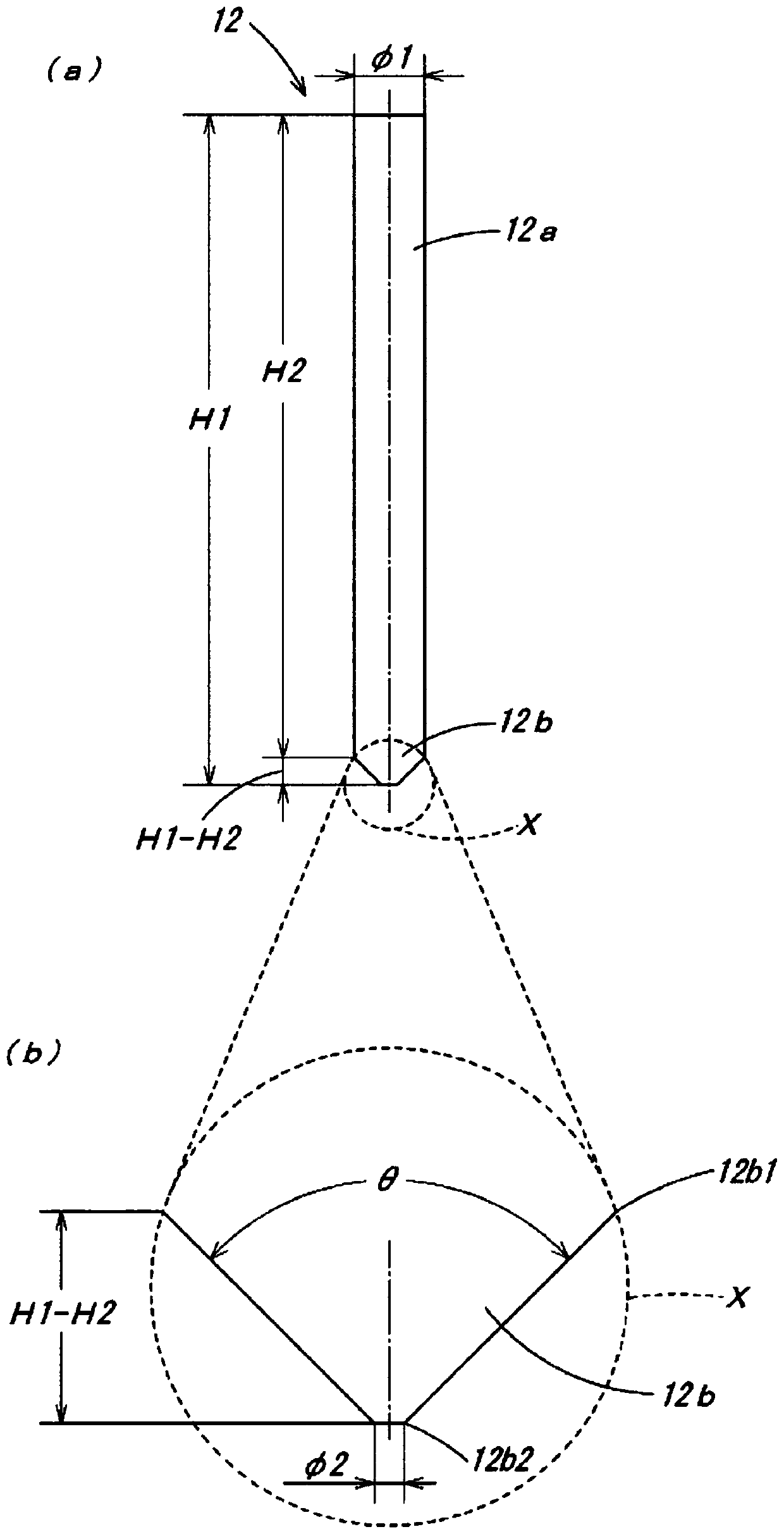

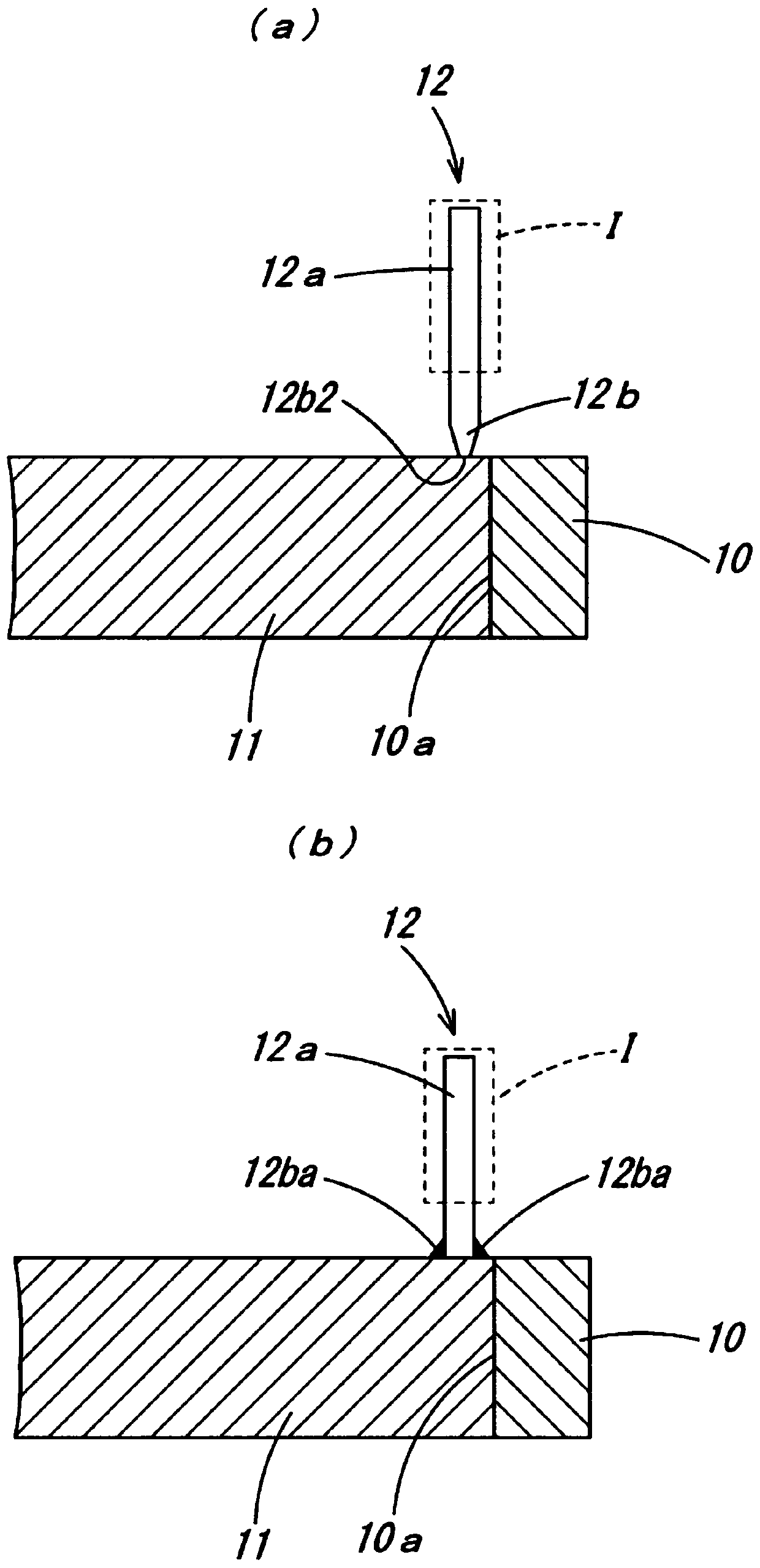

[0030] The shunt resistor of this embodiment is especially used to measure the flow from the battery to the motor in high-voltage applications used in electric vehicles (EV vehicles), hybrid vehicles (HV vehicles), plug-in hybrid vehicles (PHV vehicles), etc. The current value of the current path through which the large current of the circuit flows, such as figure 1 (a), figure 1 As shown in (b), the shunt resistor 1 is composed of a resistor body 10, a pair of base materials 11 sandwiching the resistor body 10 and integrally formed with the resistor body 10, and a measurement terminal 12 fixed to the base material 11. constitute. Resistor 10 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com