Gas inlet cleaning device and waste gas treatment device adopting same

A waste gas treatment device and cleaning device technology, which is applied in the direction of gas treatment, cleaning methods and appliances, smoke and dust removal, etc., can solve the problems of unsatisfactory demand and low waste gas treatment efficiency, and achieve cost saving, maintenance time reduction, and avoiding stuck Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

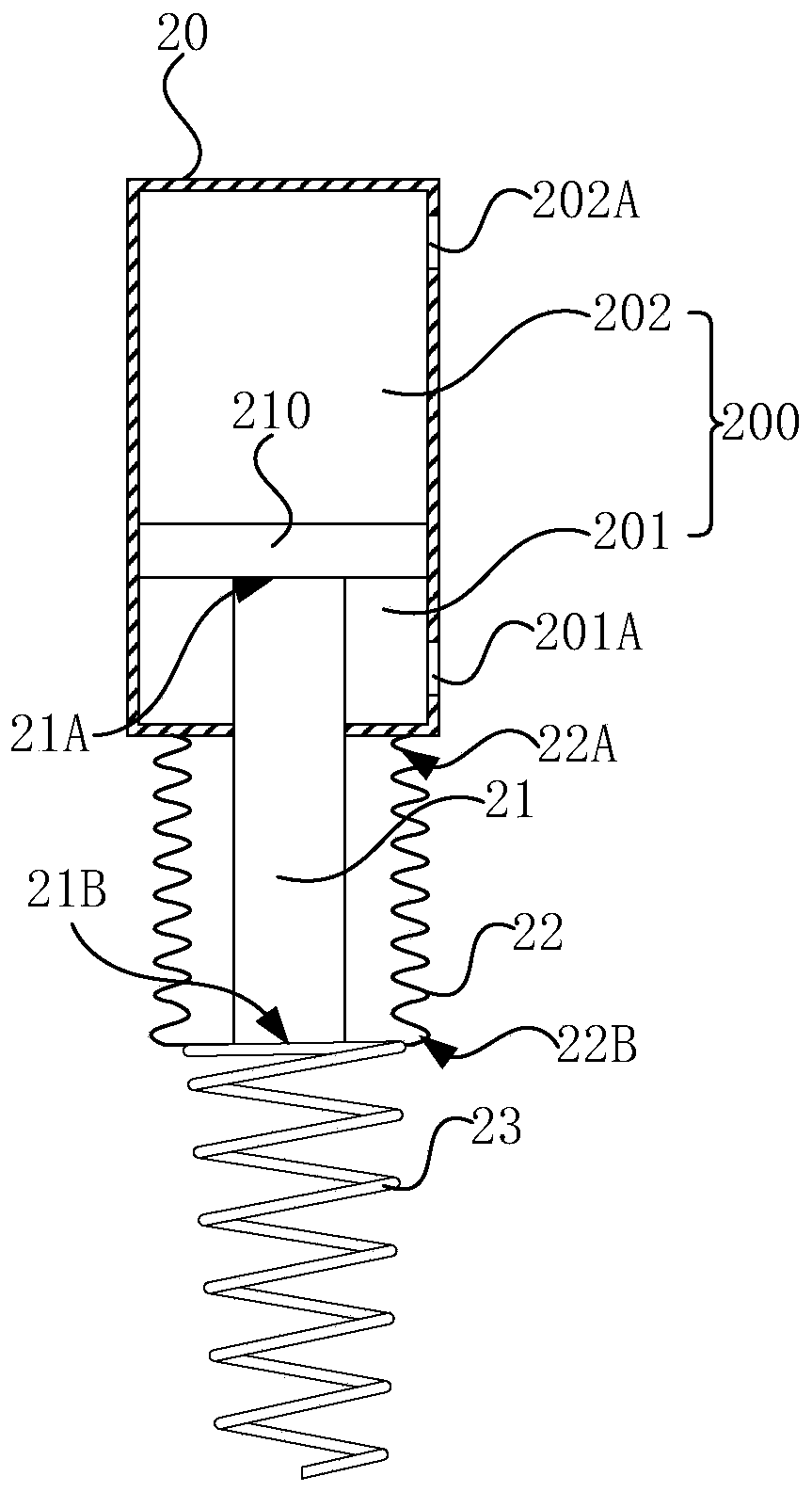

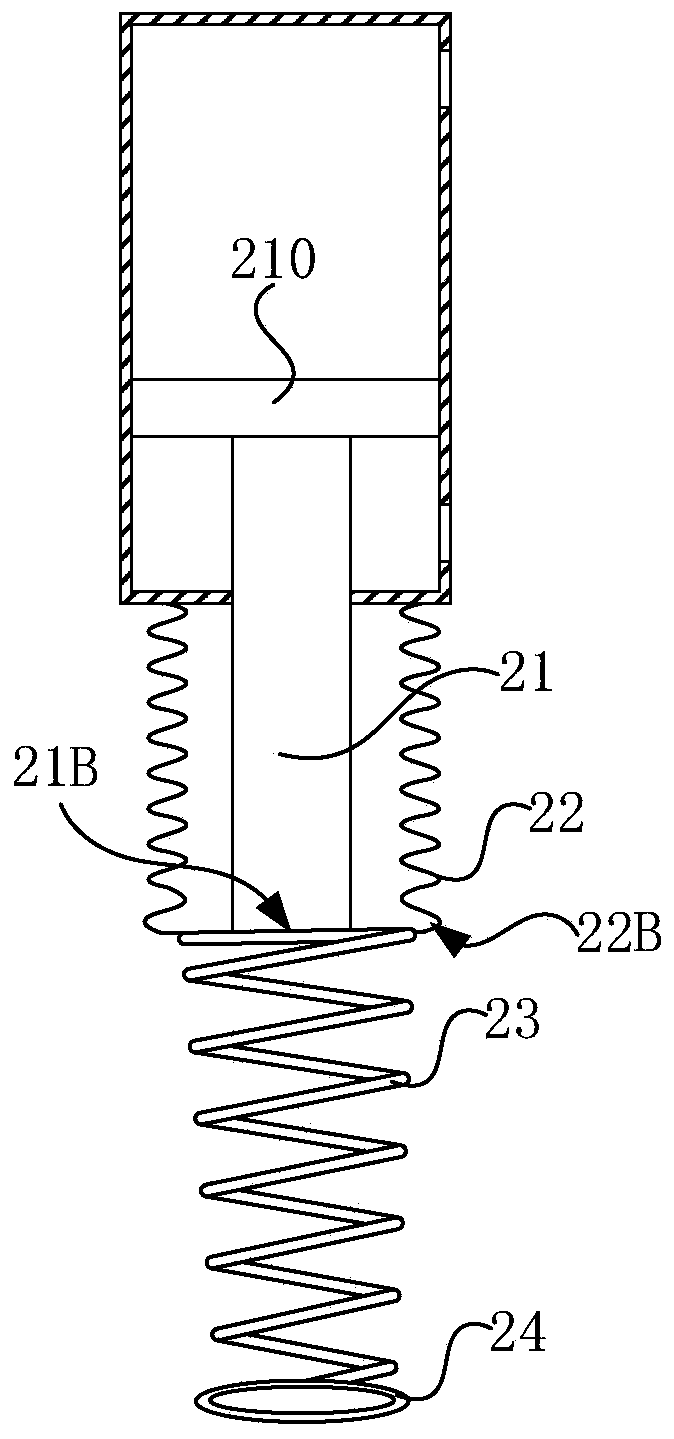

[0024] The specific implementations of the air inlet cleaning device provided by the present invention and the exhaust gas treatment device using the cleaning device will be described in detail below with reference to the accompanying drawings.

[0025] Industrial waste gas usually contains particulate matter. At the air inlet of the exhaust gas treatment device, particulate matter may accumulate and block the air inlet. Generally, an intake port cleaning device is provided at the intake port of the exhaust gas treatment device to prevent exhaust gas from accumulating at the intake port while introducing exhaust gas.

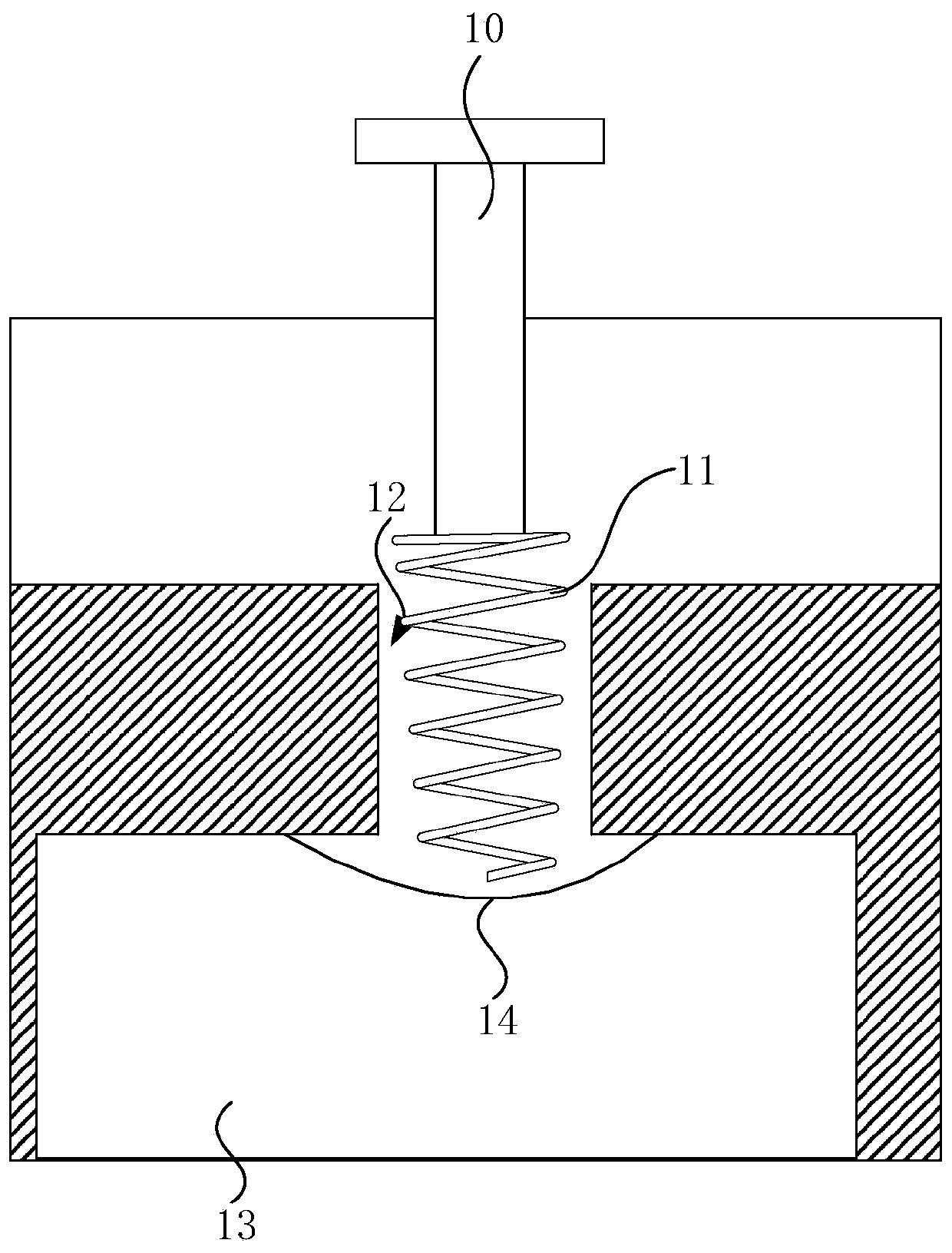

[0026] figure 1 It is a schematic diagram of an existing exhaust gas treatment device. See figure 1 The exhaust gas treatment device drives the cleaning member 11 to move in the air inlet 12 through a sliding rod 10 to clean the air inlet. Specifically, during the intake period, the cleaning member 11 moves to drive the particulate matter in the exhaust gas to move,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com