Double-air-duct cloth bag-type dust remover

A technology of bag dust collector and double air duct, which is applied in the direction of chemical instruments and methods, dispersed particle filtration, combined devices, etc., can solve the problems of poor cleaning effect, complex structure of dust cleaning device, and low degree of automation, so as to avoid Poor dust removal effect, increased filter dust removal effect, high degree of automation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

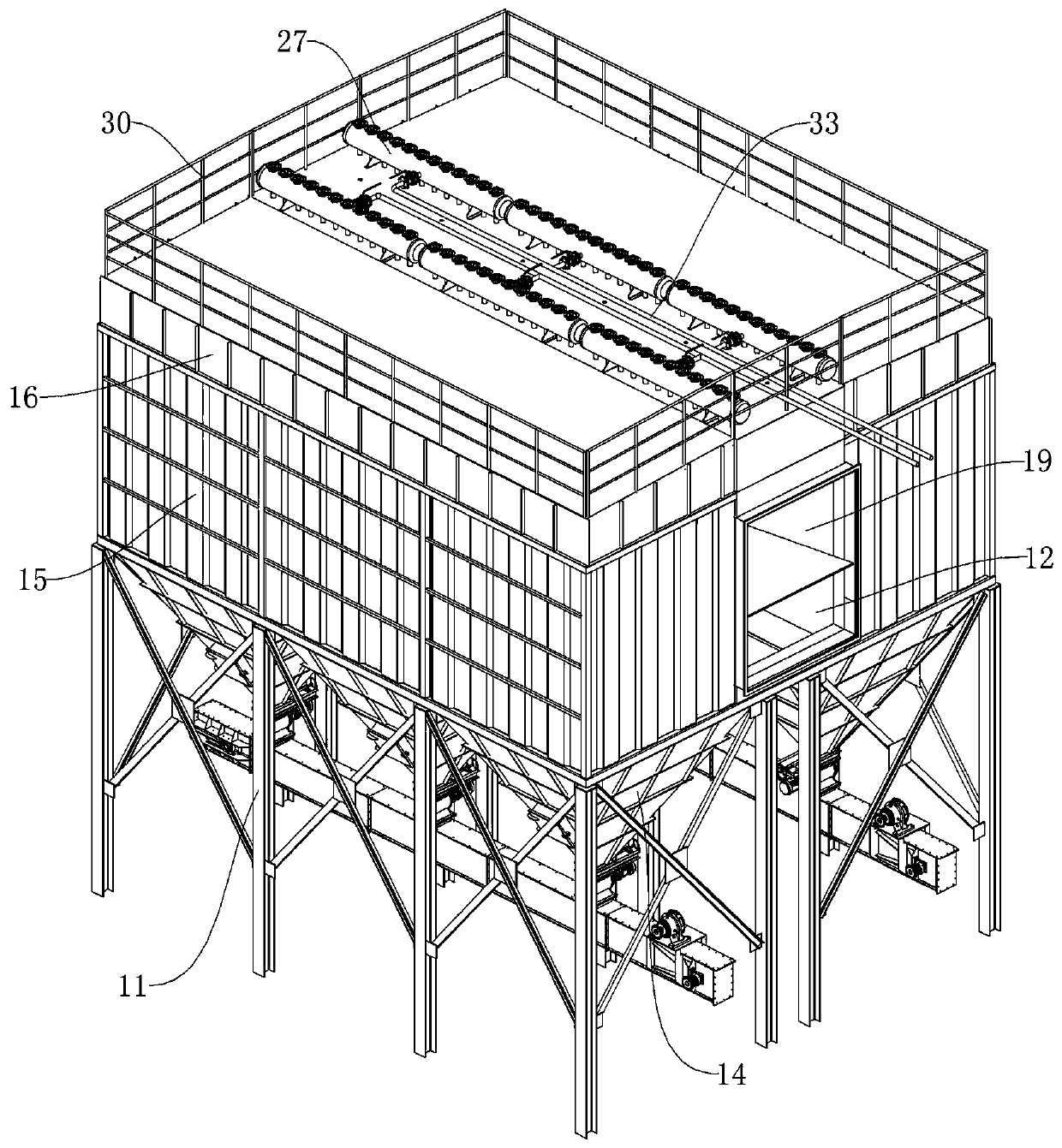

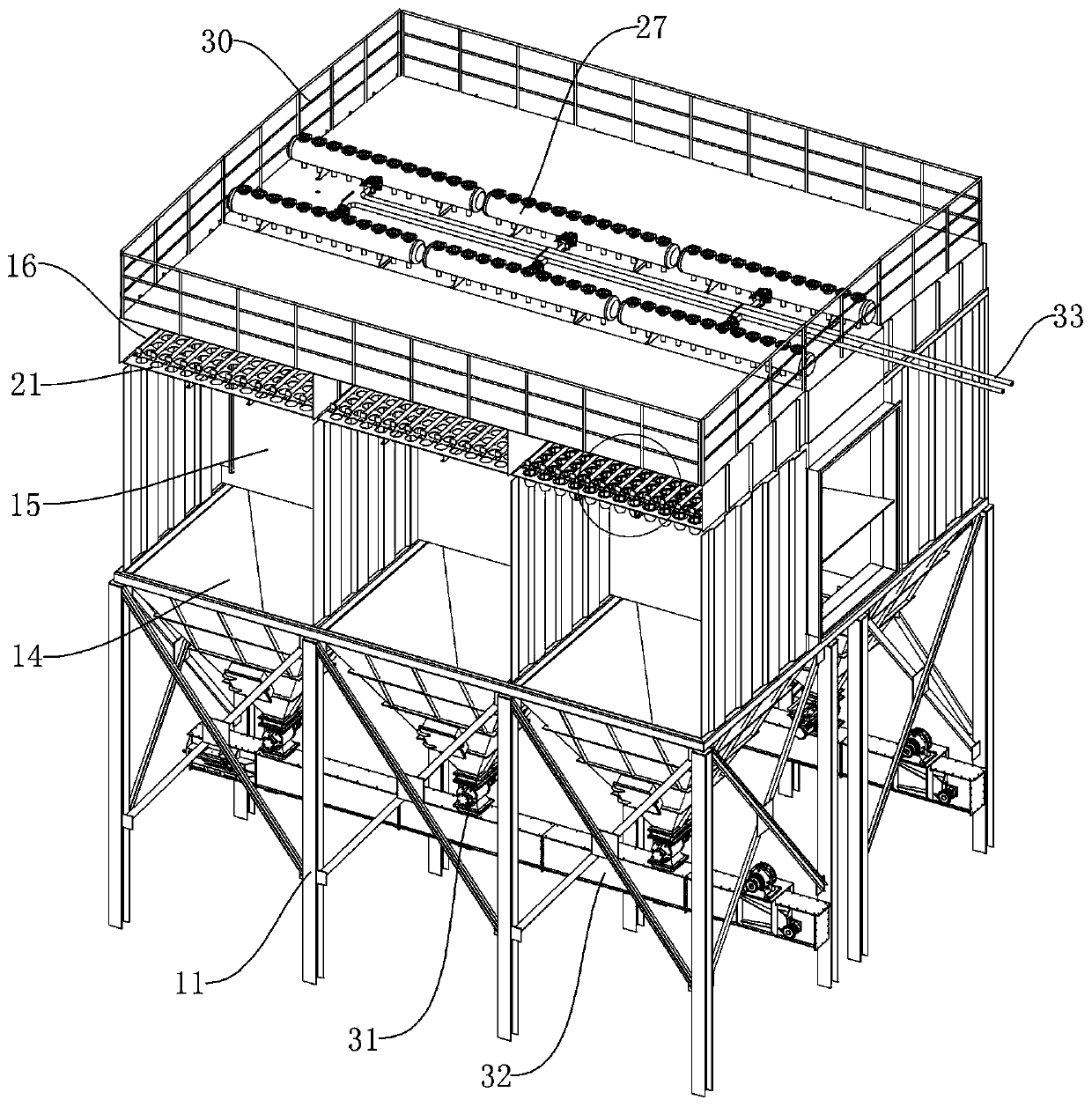

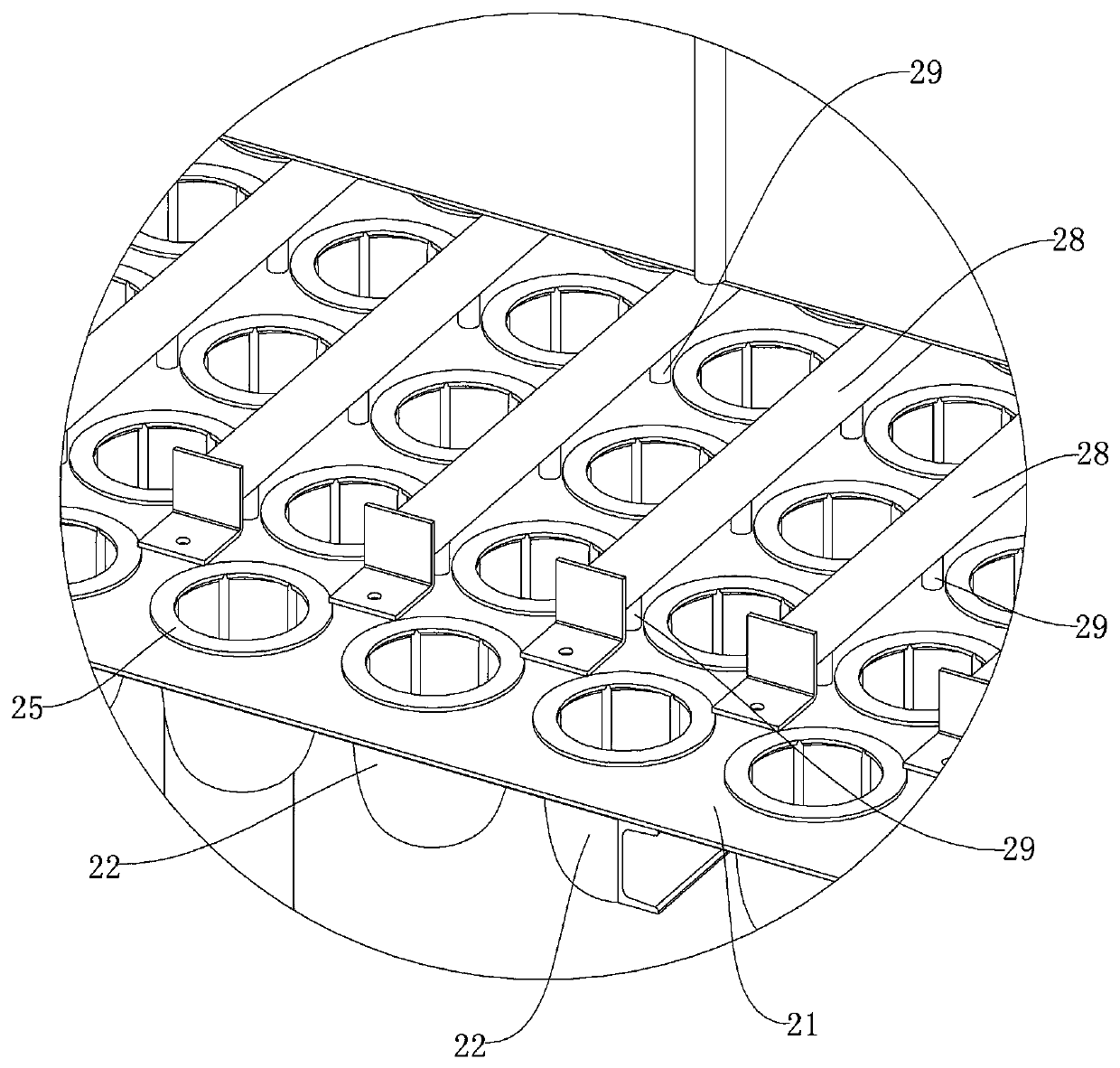

[0025] Embodiment one, refer to the description attached figure 1 - 8. A double-duct bag filter, including an air inlet and an outlet arranged in the middle above the frame, ash hoppers and dust removal chambers connected to it symmetrically arranged on both sides of the inlet, and an outlet The cleaning air chamber connected to the dust removal air chamber and the air outlet channel is set at the upper end of the upper end, and is characterized in that: the air outlet channel and the air inlet channel are separated by a middle lateral During the test, the dust-laden gas pipe and the middle bypass air duct are connected, and the dust-laden gas passes through and is discharged directly from the middle bypass air duct, replacing the existing bypass air duct surrounding the outside of the dust collector. The upper end of the ash hopper is fixedly connected with the frame, and the dust removal air chamber is connected to the upper end of the ash fall hopper and communicated with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com