A kind of preparation method of molecular sieve surface organic base etching and loading PT catalyst

A technology of molecular sieves and organic bases, applied in the direction of molecular sieve catalysts, catalyst activation/preparation, chemical instruments and methods, etc., to achieve good application prospects, facilitate dispersion and stability, and improve mass transfer properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

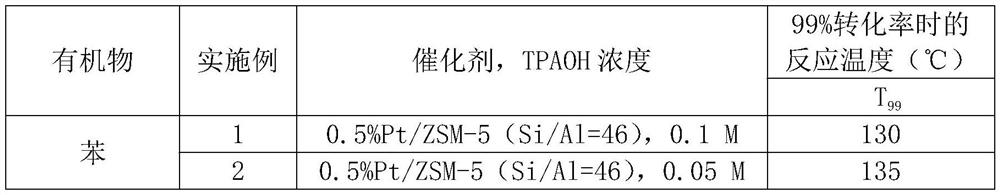

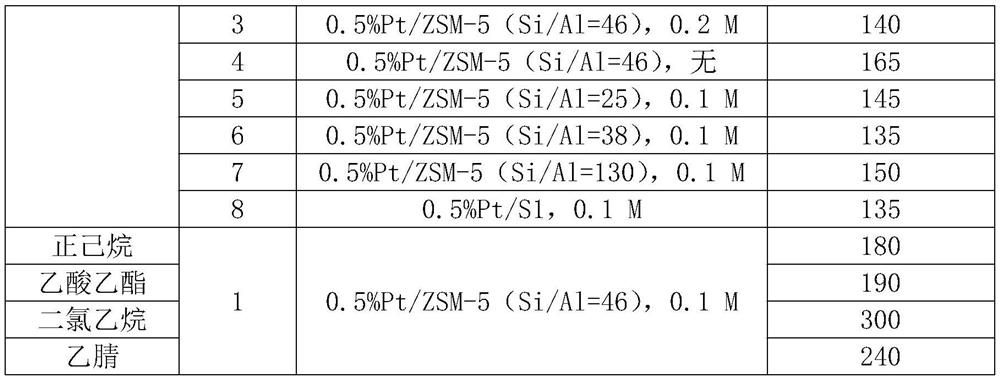

Embodiment 1

[0014] Add 3 g of powder H-type ZSM-5 molecular sieve (Si / Al=46) to 50 mL of tetrapropylammonium hydroxide (TPAOH) aqueous solution with a concentration of 0.1 M, stir at 60 ° C for 8 hours, then filter and wash with deionized water Repeatedly until the filtrate is neutral. Disperse the molecular sieve treated by organic alkali etching in 50 mL of ethylene glycol solution, stir well and add 1.5 mL of H 2 PtCl 6 Aqueous solution (15mgPt), the pH value of the mixture is 6.0, continue to stir for more than 2 hours under the protection of nitrogen, then heat up to 160°C, reflux for 6 hours, filter, wash with deionized water several times until there is no Cl in the filtrate - ions, and dried at 100°C to prepare a Pt / ZSM-5 (Si / Al=46) catalyst with a Pt loading of 0.5%.

Embodiment 2

[0016] The same operation as in Example 1 was used, except that the concentration of the TPAOH aqueous solution was changed to 0.05M to prepare a Pt / ZSM-5 (Si / Al=46) catalyst with a Pt loading of 0.5%.

Embodiment 3

[0018] The same operation as in Example 1 was used, except that the concentration of the TPAOH aqueous solution was changed to 0.2M to prepare a Pt / ZSM-5 (Si / Al=46) catalyst with a Pt loading of 0.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com