Automatic control system of industrial robot

An industrial robot and automatic control technology, which is applied in the direction of program control manipulator, manipulator, manufacturing tools, etc., can solve the problems of inability to meet the real-time and reliability requirements of high-end numerical control devices, low degree of automation, poor expandability, etc., to achieve improved Stability and positioning accuracy, improving real-time performance and accuracy, improving intelligence and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] In order to further understand the content, features and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings.

[0058] The structure of the present invention will be described in detail below in conjunction with the accompanying drawings.

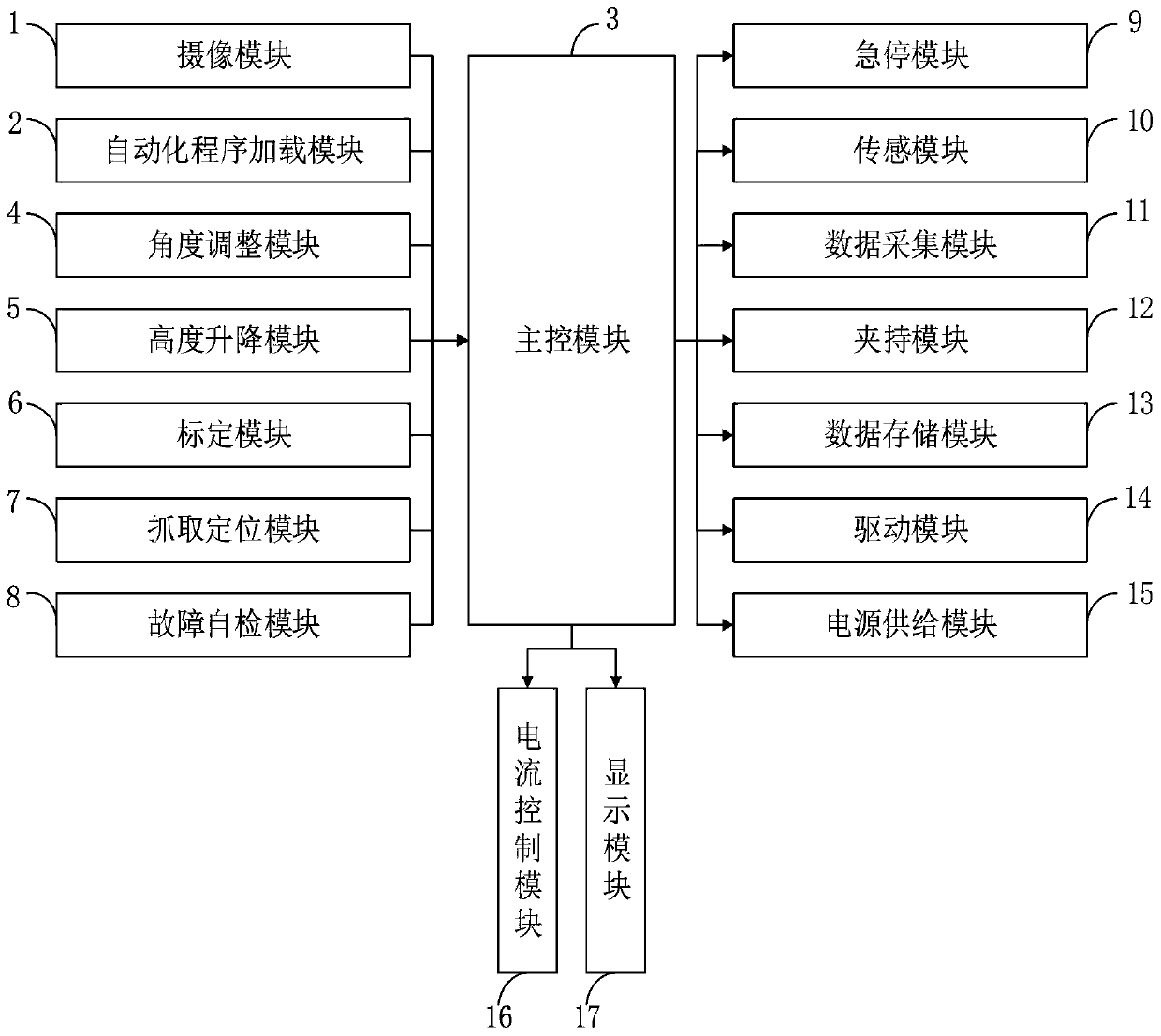

[0059] Such as figure 1 As shown, the automatic control system of the industrial robot provided by the embodiment of the present invention includes: a camera module 1, an automatic program loading module 2, a central control module 3, an angle adjustment module 4, a height lifting module 5, a calibration module 6, and a grasping and positioning module 7. Fault self-inspection module 8, emergency stop module 9, sensing module 10, data acquisition module 11, clamping module 12, data storage module 13, drive module 14, power supply module 15, current control module 16, display module 17 .

[0060] The camera module 1 is connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com