Special device for soldering and sealing relay

A special device and relay technology, used in welding equipment, auxiliary devices, welding/welding/cutting items, etc., can solve the problem of uniform product sealing and welding strength difficult to ensure, parts positioning and heating uniformity difficult to ensure, tooling and disassembly. It can improve the positioning accuracy and stability, achieve uniform spreading, and improve the craftsmanship.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

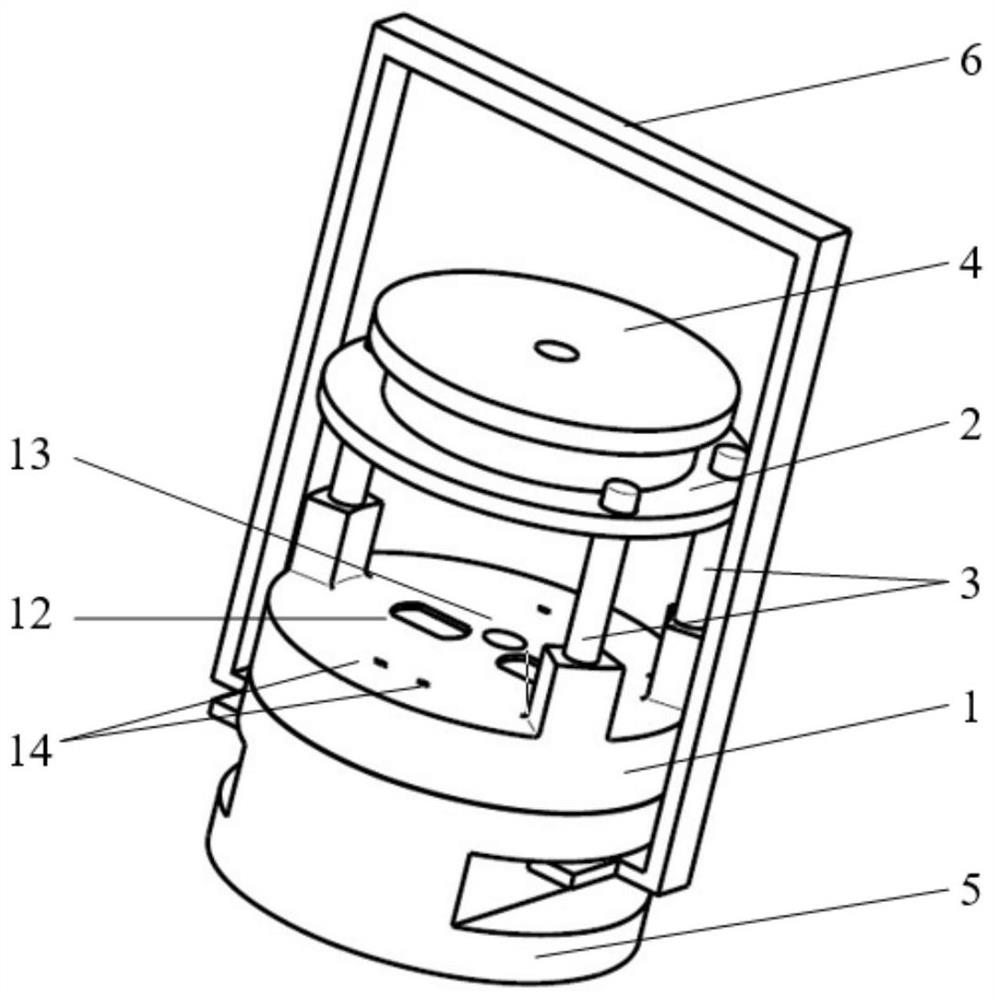

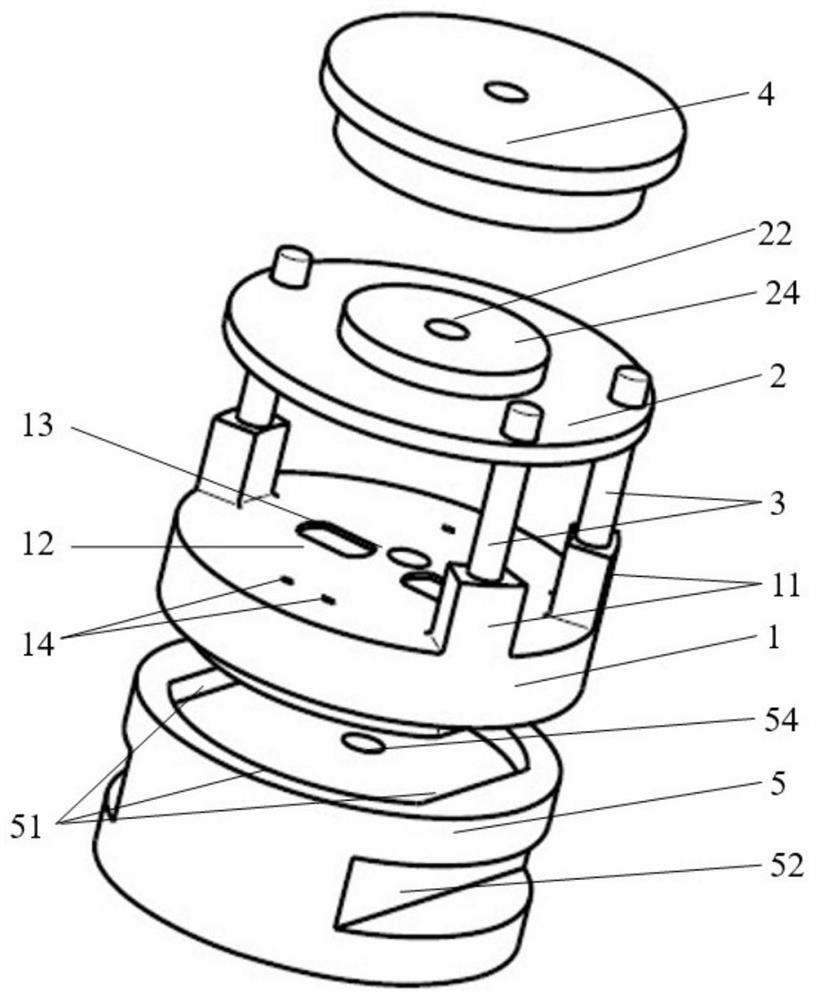

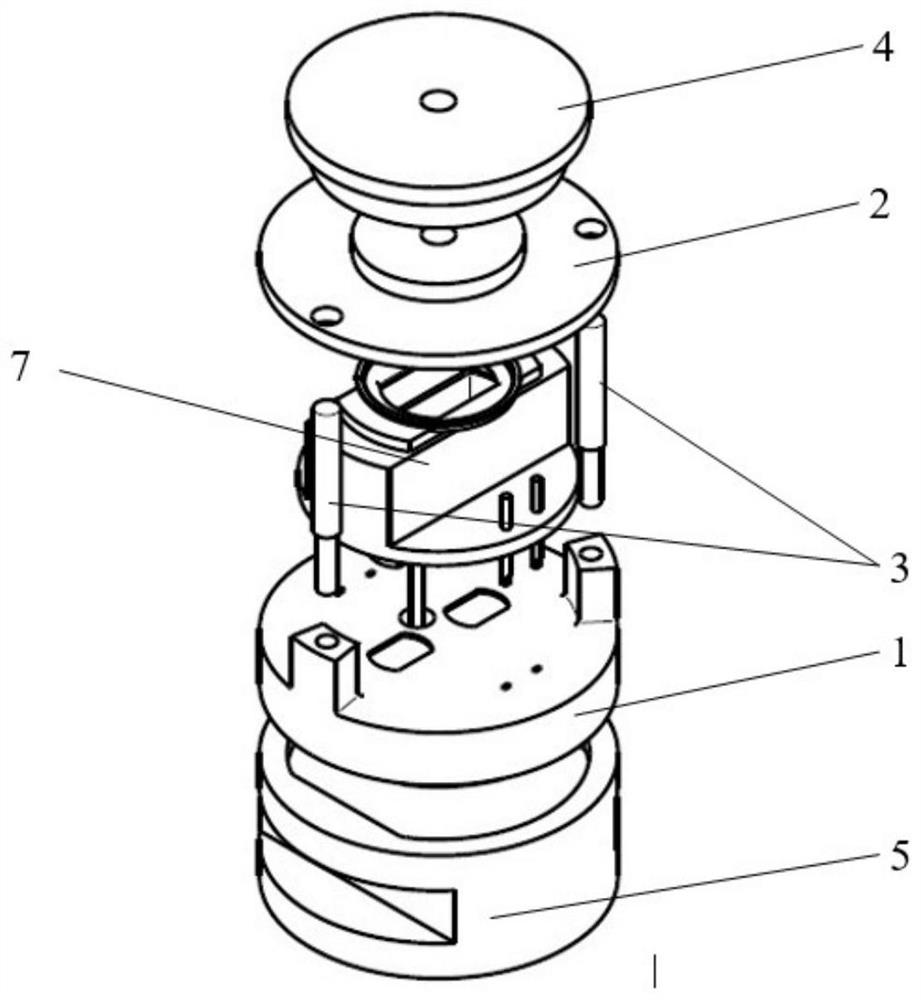

[0065] The special device for soldering and sealing relays of the present invention (hereinafter referred to as the special device for brazing) adopts the technical scheme of one-time positioning of the parts to be welded and one-time completion of welding. At the same time, the special device for brazing of the present invention adopts anti-mis-insertion and guide design, and uses its own weight to perform its own positioning. There are no connecting parts such as screws, and it is easy to disassemble and clean, and it is not easy to loosen and tip over when lifted.

[0066] as attached Figure 1-3 And attached Figure 10 As shown, when the ceramic seat 71 and the connecting ring 72, the static contact 73, the exhaust pipe 74, the terminal post 75 and other parts to be welded form the assembly 7 to be welded, the special device for brazing of the present invention can complete all the parts to be welded at one time. The positioning of the parts. The specific assembly form o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com