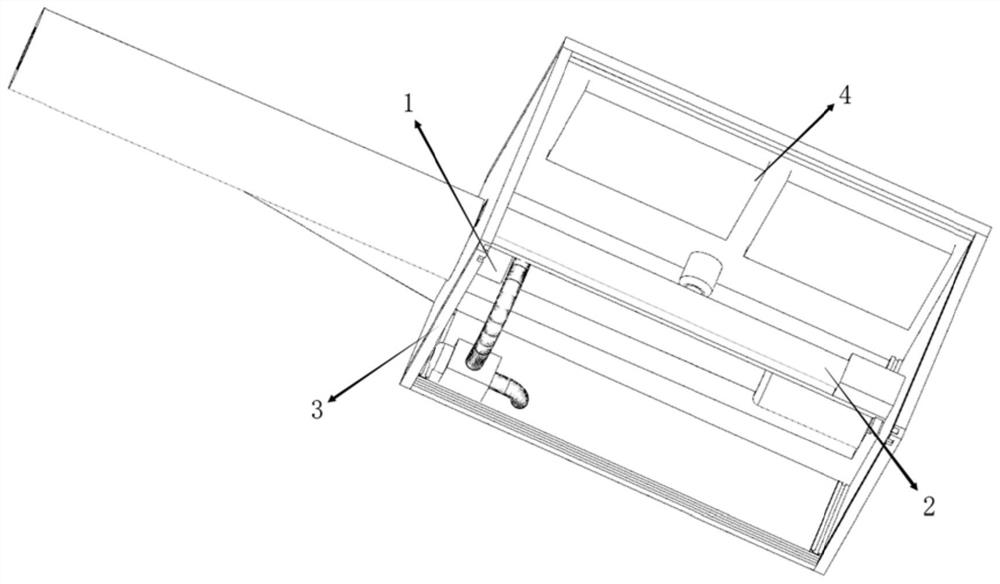

An integrated temperature measurement device for an annular cooler with simultaneous measurement by two temperature measurement methods

A ring cooler and temperature detector technology, applied in the field of iron and steel metallurgy, can solve the problems of temperature measurement error, influence, easy damage, etc., and achieve the effect of slowing down the dust raising, slowing down the flow speed, and improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

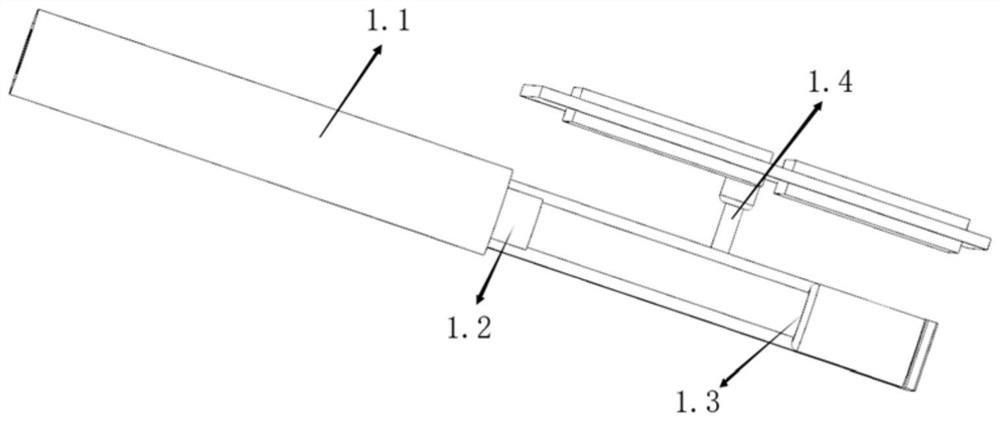

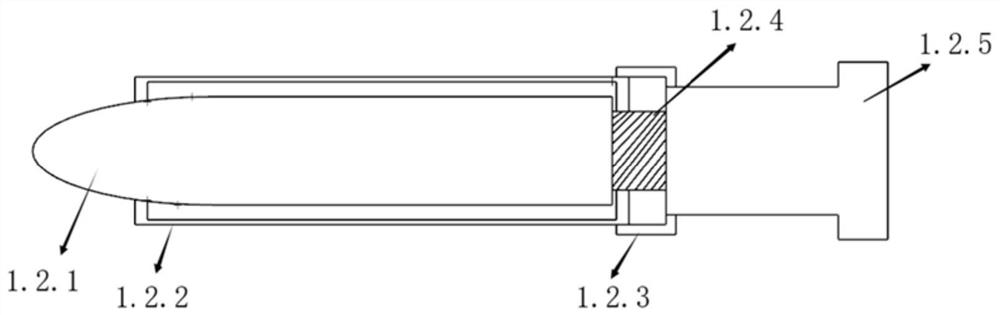

Method used

Image

Examples

specific Embodiment 2

[0068] Specific embodiment 2, the present invention discloses a method for replacing the components of the integrated temperature measurement device of the annular cooler, which is characterized in that when the maintenance alarm needs to be replaced with the thermocouple 1.2.1 of the present invention and other replacement and cleaning, the components are replaced The method is implemented as follows:

[0069] Step 1, input the repair instruction in the control unit (MCU) 4.2, at this time the control unit (MCU) 4.2 controls the second push rod motor 1.4 to shrink to the shortest, tilt the slider 3.4 and the first push rod fixed on it and shrink to the shortest distance The rod motor 1.3 and the thermocouple temperature detector 1.2 not inserted into the first protection tube move to the side of the operation unit 4 until they stop, so as to facilitate the replacement of parts by the staff.

[0070] Step 2. The staff first removes the left board 3.5.1 of the mounting case on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com