Workbench special for hardness detection equipment for steel plate production

A technology of testing equipment and workbench, applied in the direction of testing material hardness, measuring device, strength characteristics, etc., can solve problems such as good matching and positioning effect, and achieve good matching and positioning effect, driving control effect, and use effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

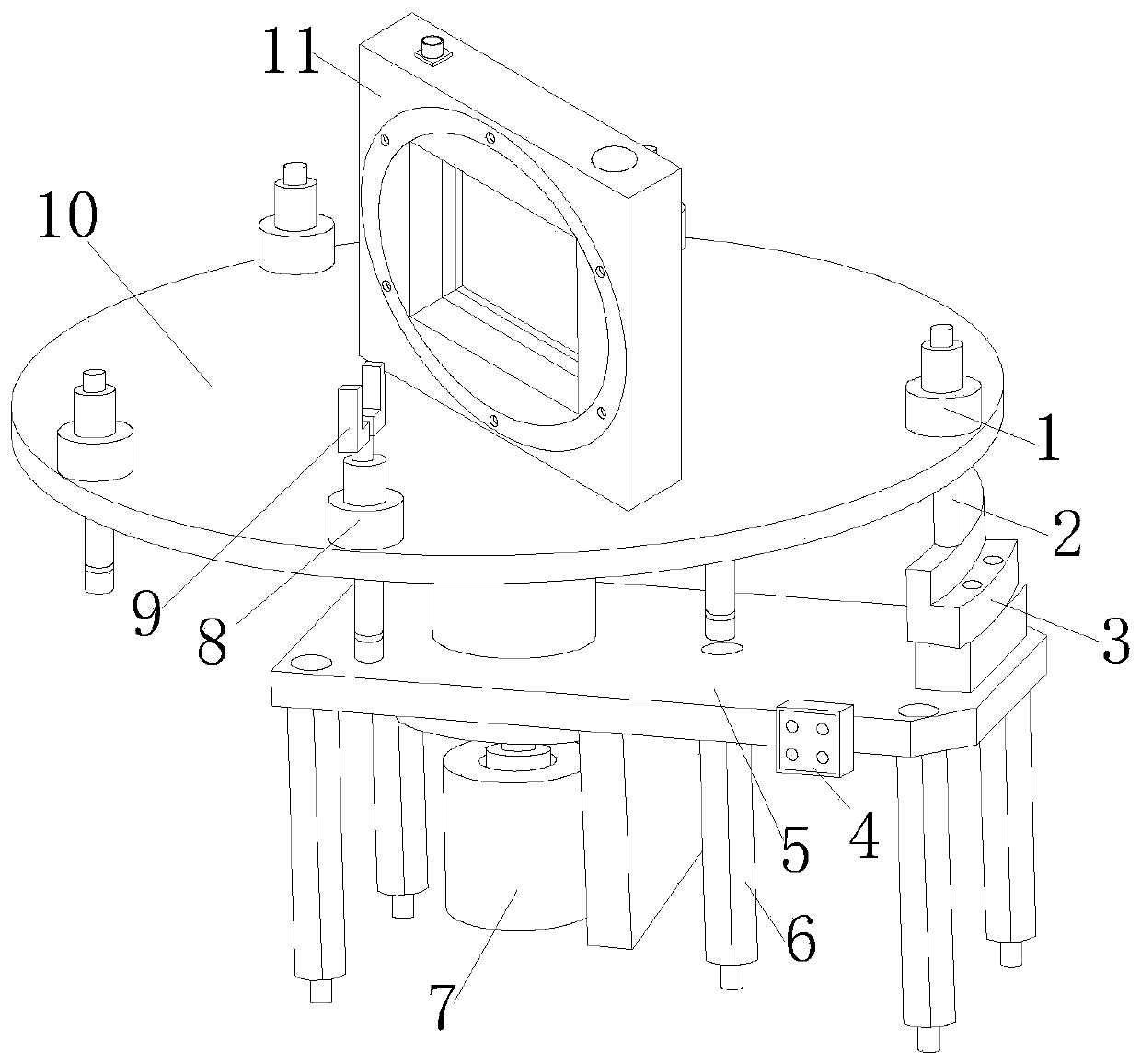

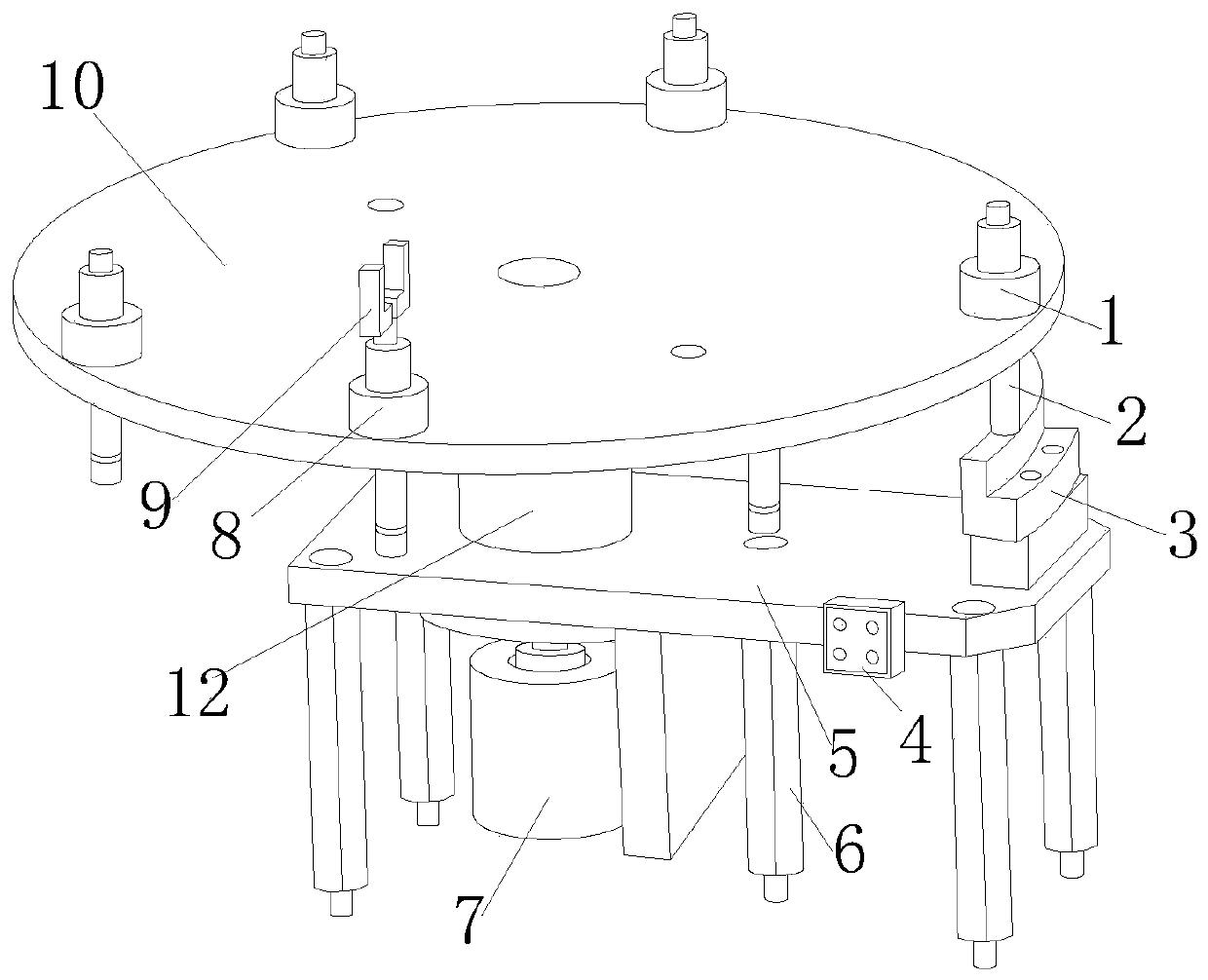

[0028] see figure 1 with figure 2 , the present invention provides a special workbench for hardness testing equipment for steel plate production through improvement, including a bottom platform 5 and a detection piece 11, a detection platform 10 is installed in parallel above the bottom platform 5, and the bottom end of the detection piece 11 is fastened and installed on the detection On the platform 10, a control box 4 is installed on the bottom platform 5, which is convenient to control the opening and closing of the rotating motor 7. The bottom of the bottom platform 5 is welded and fixed with a foot 6, which is convenient for stably supporting the bottom platform 5. The bottom of the bottom platform 5 A rotating motor 7 is installed on the side lock, and a rotating cylinder 12 is installed on the rotating motor 7. The upper surface of the detection table 10 is equipped with a matching bottom cylinder 8 and a fastening screw cylinder 1, and a positioning claw 9 is installe...

Embodiment 2

[0034] The present invention provides a special workbench for hardness testing equipment for steel plate production through improvement. The bottom support platform 3 is fitted with a round opening corresponding to the insertion rod 2, and the fitting and connection effect is good. The insertion rod 2 The bottom end is fixedly installed on the bottom platform 5, and the restriction and fixing effect after use is good, and the number of the fastening screw barrels 1 is greater than two.

[0035] The present invention provides a special workbench for hardness testing equipment for steel plate production through improvement, and its working principle is as follows;

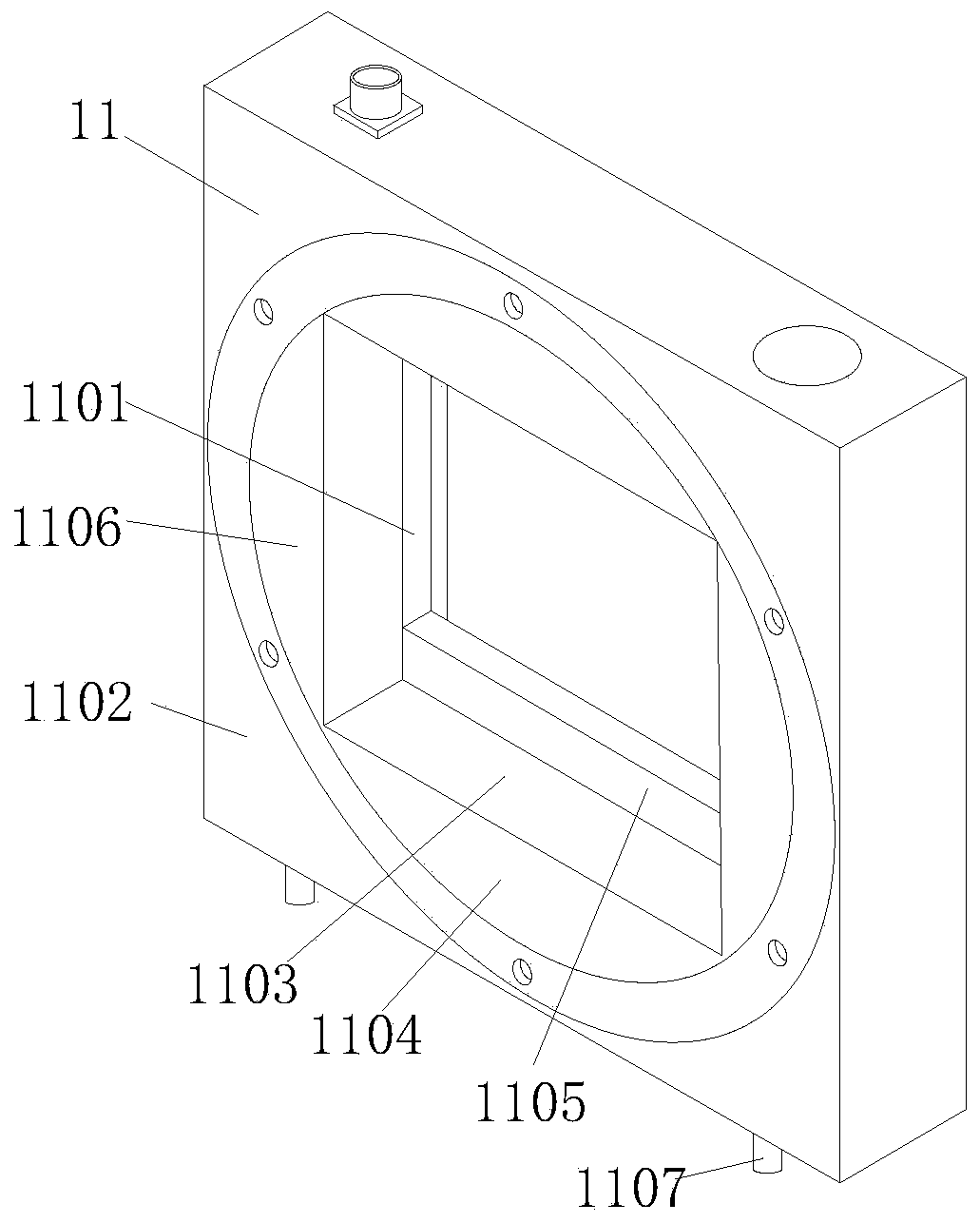

[0036] First, when in use, the special workbench for hardness testing equipment for steel plate production is installed and placed on the corresponding position in the workshop, and a steel plate is extracted from the steel plate production room, and it is placed horizontally at the position of the pressure groove 110...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com