Cigarette heat treatment process quality analysis device and analysis method

A quality analysis device and the technology of the analysis device, which are applied in the application field of the tobacco industry, can solve the problems of high processing intensity, influence on the quality of cigarette products, neglect of changes in tobacco chemical substances, etc., so as to improve the accuracy and scientificity, and help to guide on-site production. , Overcome the effect of high temperature and high humidity environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

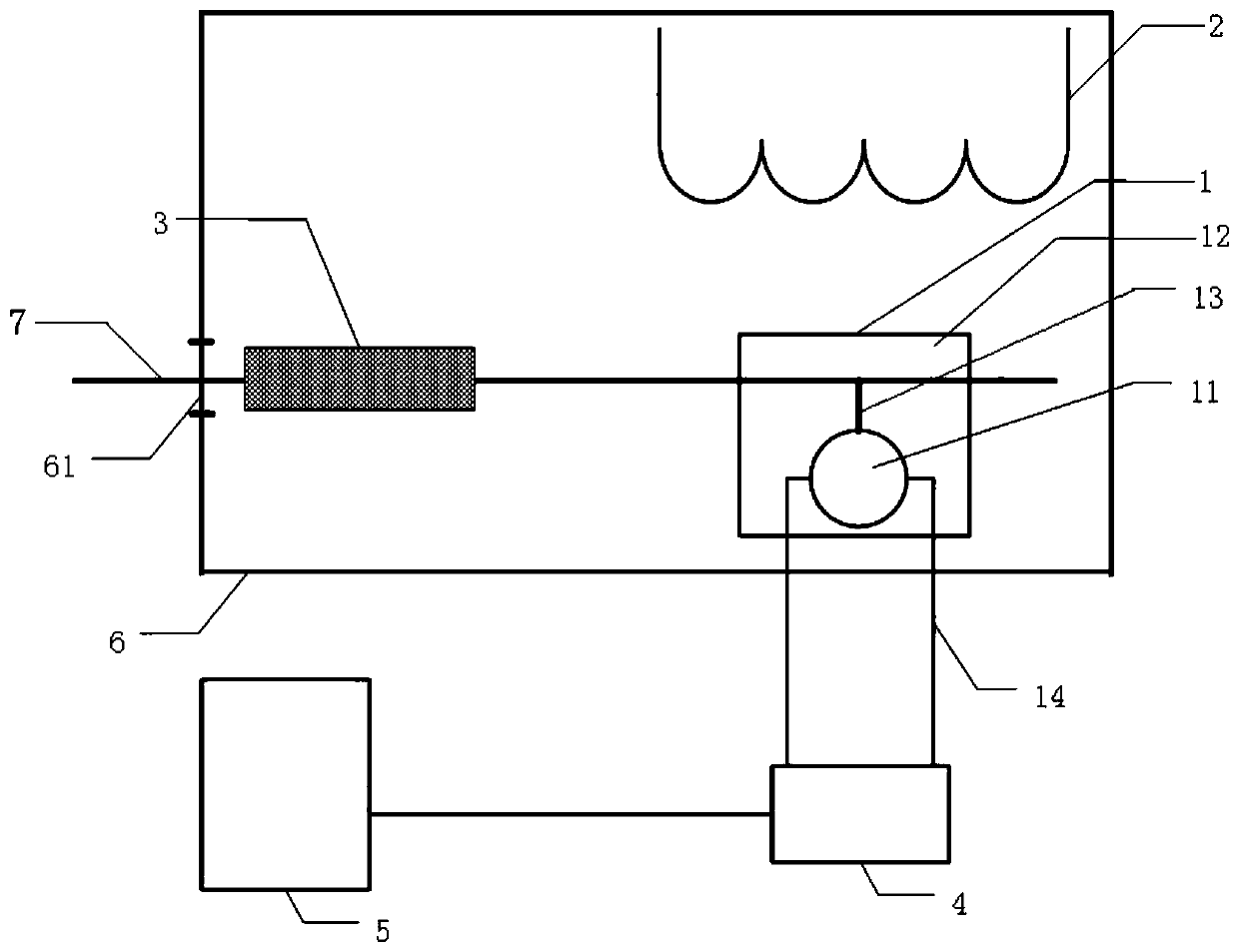

[0039] like figure 1 As shown, the cigarette heat treatment process quality analysis device of the present invention includes: a gas sensor 1, a heater 2, a dehumidifier 3, a data acquisition memory 4, and a display 5;

[0040] The dehumidifier 3 is arranged at the entrance of the gas sensor 1, and the dehumidifier 3 and the gas sensor 1 are packaged in a detection chamber 6, and the detection chamber 6 is in gas communication with the intake pipe 7;

[0041] One end of the data acquisition memory 4 is connected to the gas sensor 1 , and the other end is connected to the display 5 .

[0042] The size of the gas sensor 1 is 5×5×2 cm.

[0043] The dehumidifier 3 has a gas-water separation device to effectively separate the water vapor and volatile chemical substances emitted from the tobacco after the heat treatment process, so as to prevent the gas-sensitive materials from becoming invalid due to the water vapor.

[0044] The bottom of the detection chamber 6 has a detection ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com