Human-driven single-knife cutting wire stripping device

A human-driven, cutting technology, applied in the direction of cable installation device, cable installation, circuit, etc., can solve the problem of laborious wire insulation sleeve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

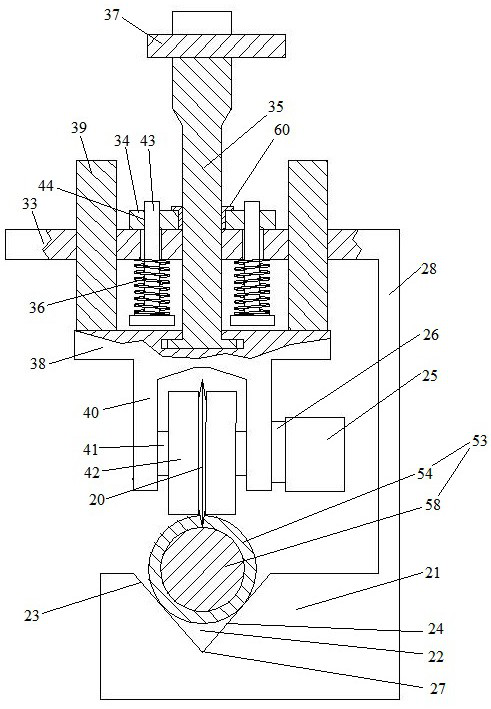

[0021] Embodiment one, see figure 1 , a human-driven single-knife cutting type wire stripping device, including a support table 21 and a cutting knife assembly. A "V"-shaped centering straight groove 22 extending along the front-to-back direction is provided on the support table. The inclination angle of the left side wall 23 of the centering straight groove is equal to the inclination angle of the right side wall 24 of the centering straight groove. The cutting knife assembly comprises a circular cutting blade 20, a fixed plate 33, a movable plate 34, a blade mounting bar 35 and a blade pressing spring 36 that drives the movable plate to abut against the fixed plate. The fixed plate is connected on the support platform through the stand 28. The movable plate is provided with a through hole, and an internal thread sleeve 60 is fixed in the through hole. The inner space of the internal thread sleeve constitutes the threaded hole on the movable plate. One end of the blade mo...

Embodiment 2

[0023] Embodiment two, the difference with embodiment one is:

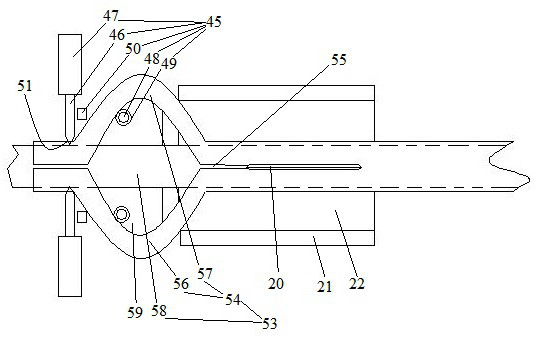

[0024] see figure 2It also includes a pair of sleeve core separation mechanisms 45 distributed along the axial direction of the feed wheel to separate the part of the wire insulation sleeve cut by the circular cutting blade from the wire conductive core. The sleeve core separation mechanism includes a push rod 46, a push rod driving cylinder 47 for driving the push rod to be pressed onto the wire insulation sleeve, and a cylinder extending in the up and down direction for blocking between the conductive core of the wire and the wire insulation sleeve in a separated state. Separation rod 48, driving separation rod lifting cylinder 49 of separation rod lifting and withstood the wire insulation sleeve when the push rod leaves the wire insulation sleeve and makes the cross push rod 50 separate from the wire insulation sleeve. A nail head 51 is provided at one end of the wire insulating sleeve on the top of the horiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com