Reel tower type uv printing system

A printing system and tower technology, applied in the field of reel-tower UV printing systems, can solve the problems of inability to improve printing efficiency, smearing and smearing of printed images, and inability to meet printing speed, etc. Wide range of effects for easy installation and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

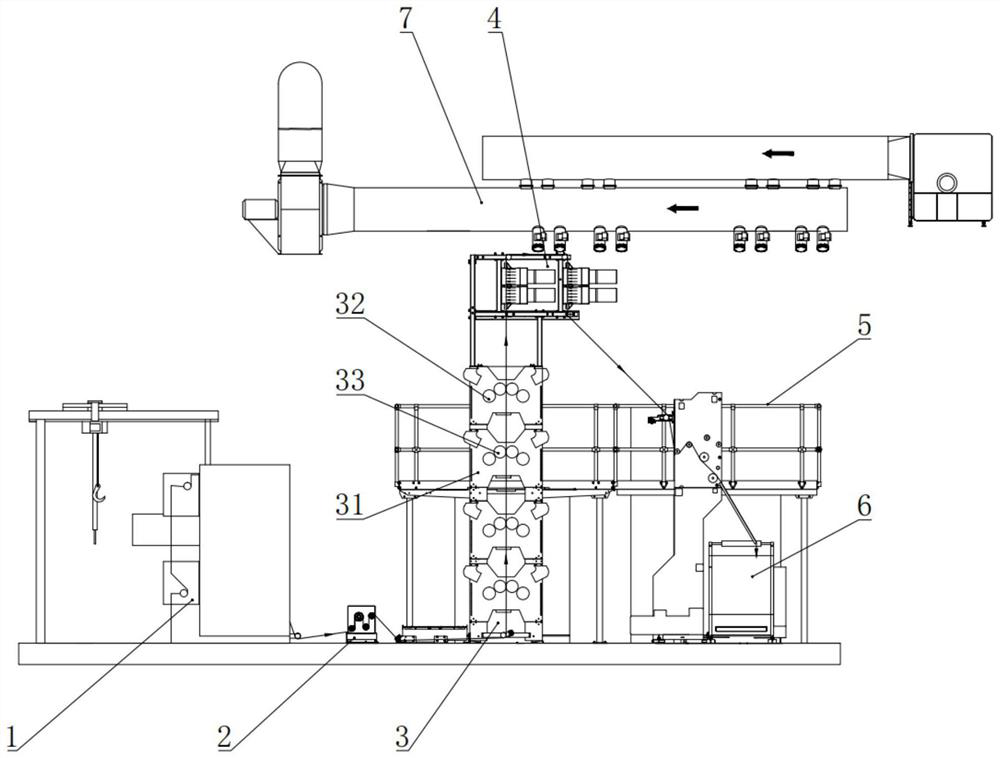

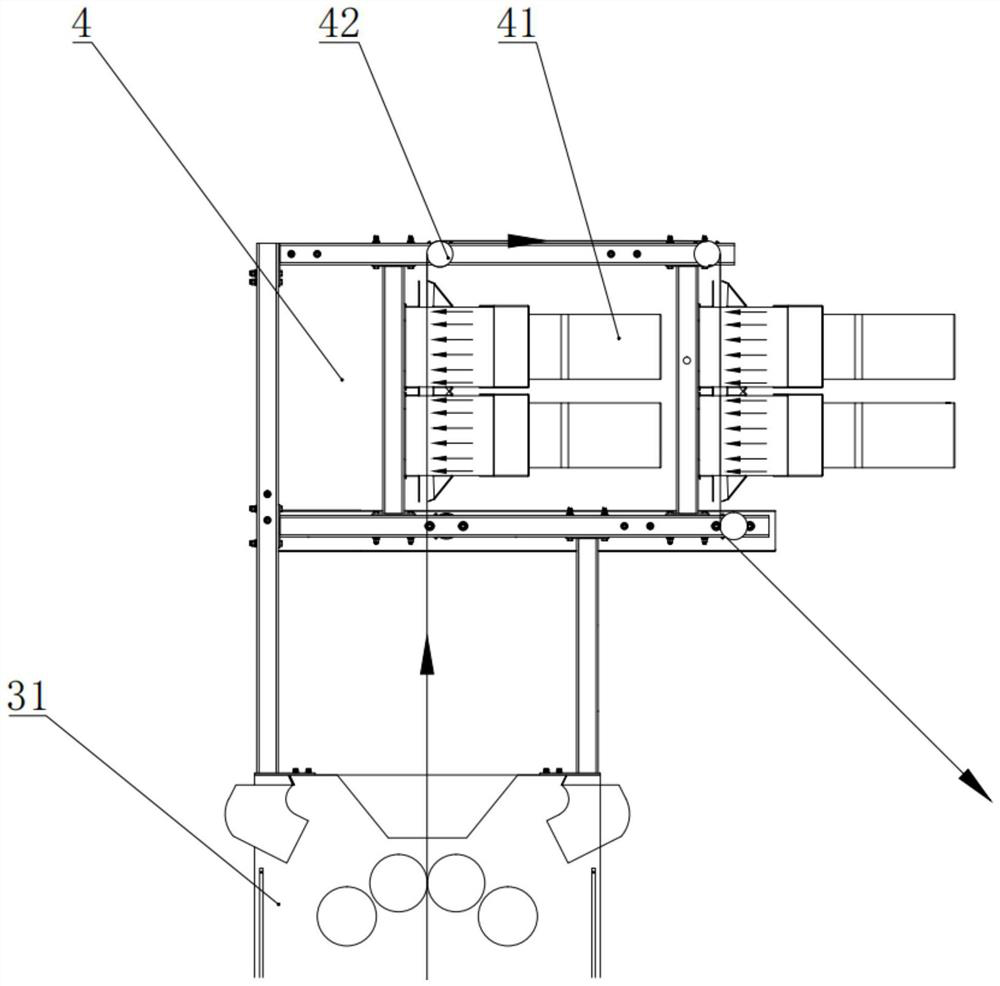

[0034] like figure 1 and figure 2 As shown, the cartridge tower UV printing system includes a sequential web feed device 1, a tension control device 2, a printing tower 3, a UV drying device, and a folding machine 6; the printing tower 3 includes a longitudinal direction At least two printing units 31, each printing unit 31 includes a paper surface including a transmission shaft, a plate drum 32, and a printing roller 33, an ink printing drum 32, and a printing roller 33, and a paper surface. Each print unit 31 can perform printing of two color inks; the UV drying device is disposed at the top of the printing tower 3, and the UV drying device includes two sets of UV dryer 41 disposed vertically vertically. A preferred drying method is, the two sets of UV dryers 41 are configured with respect to the paper strip, thereby directly drying the ink on both sides of the paper, saving mounting space, shortening the time required for drying. Another preferred drying mode is arranged in par...

Embodiment 2

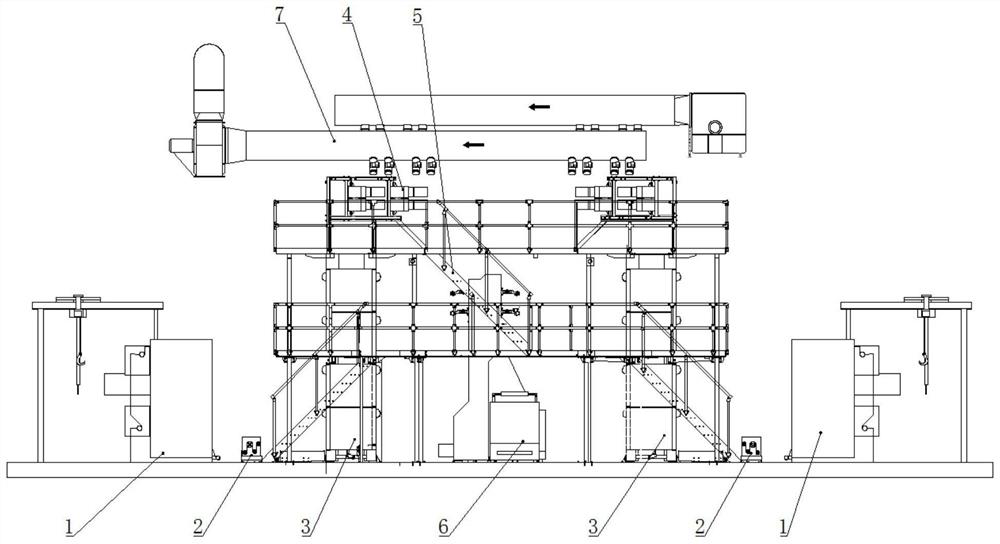

[0040] The present embodiment differs from the first embodiment in that, as image 3 As shown, the printing tower 3 in the reel tower UV printing system is at least two, and the multi-group annitime clutch unit above the folding machine 6 is used to meet a variety of printing products. The need, while reducing the number of occupied spaces and equipment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com