Battery module for improving charging rate and efficiency of terminal equipment and working method thereof

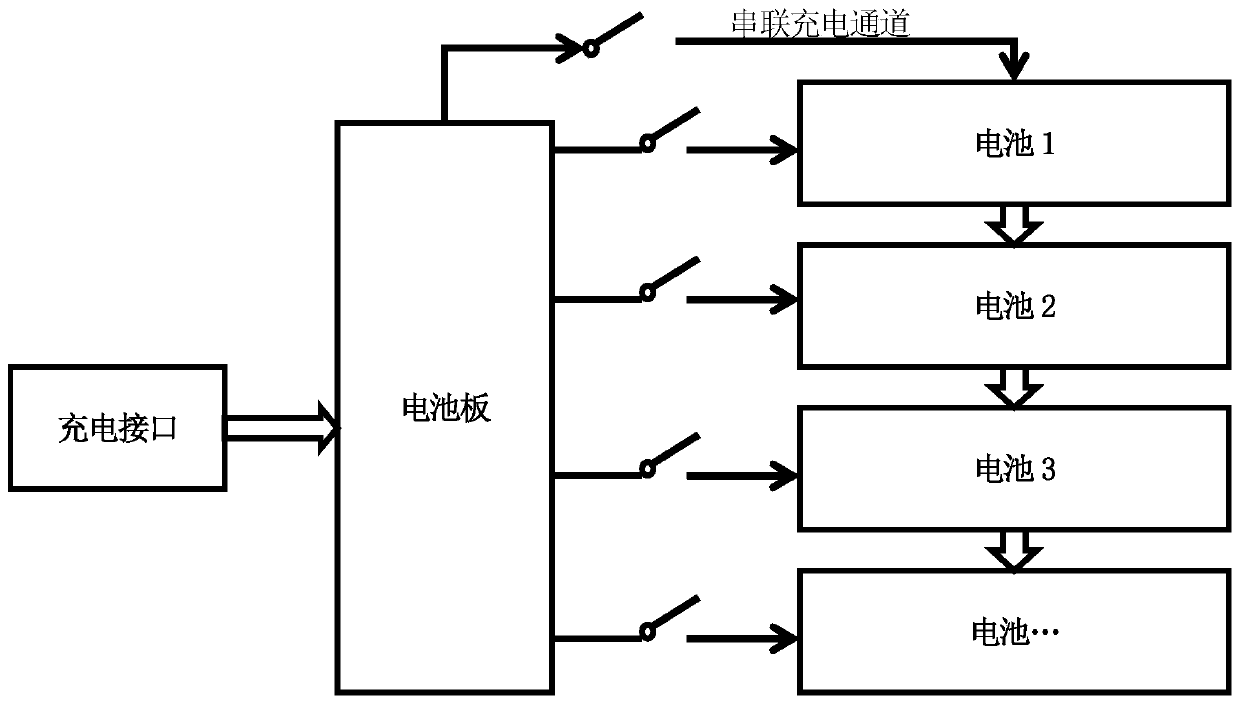

A battery module and charging rate technology, which is applied to battery circuit devices, measuring power, and current collectors. It can solve problems such as long charging time, battery temperature rise, and charging heat, and achieves the contradiction between heating, improving charging speed, and The effect of reducing the charging current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below with reference to specific embodiments, but it is not intended to limit the present invention.

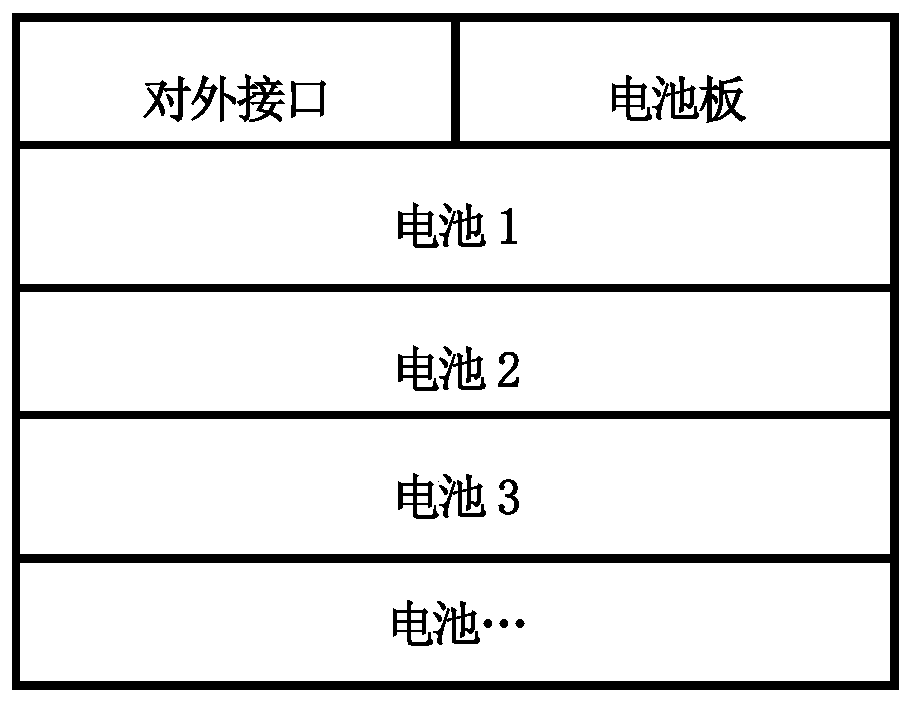

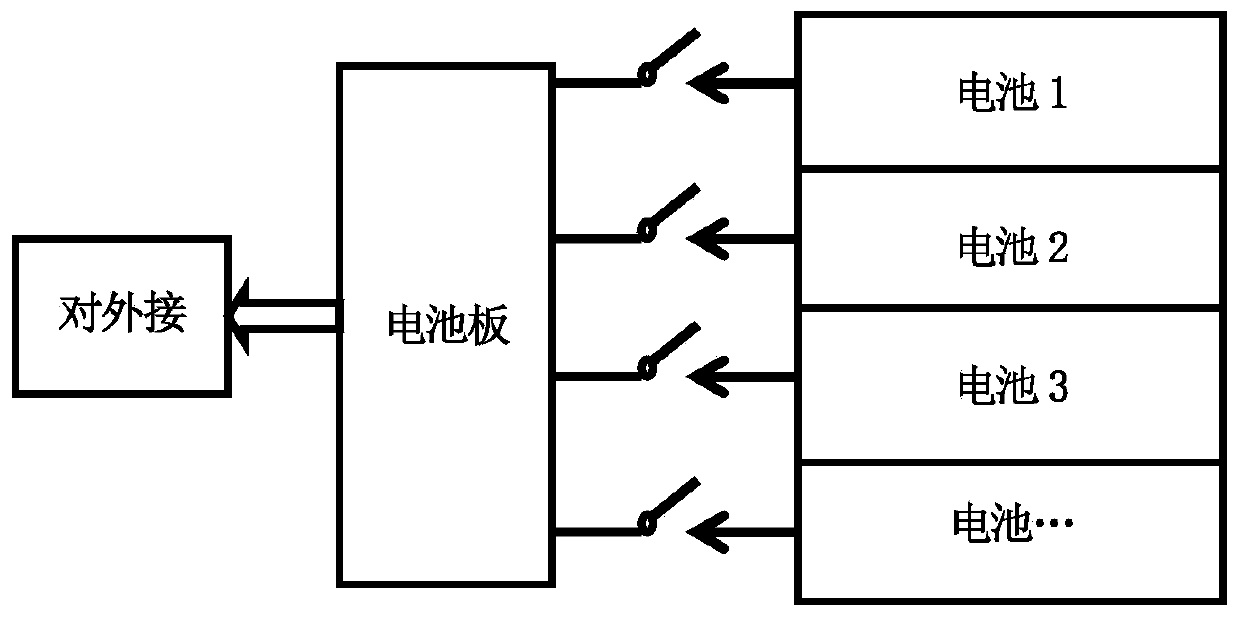

[0025] Such as figure 1 As shown, the battery module of the present invention includes a battery pack composed of several batteries, a battery board and an external interface provided on the battery board; taking a lithium battery module as an example, a lithium battery module contains exactly the same multiple pieces of lithium For batteries, the output voltage of each internal battery is consistent with the voltage required by the terminal equipment. It is recommended to use 2-3 batteries to form a battery pack in a package. The current, output voltage and internal resistance of each battery in the battery pack are completely consistent. The external interfaces of each battery are unified into one group.

[0026] The external interface includes battery output positive, battery negative, battery ID pin, and battery ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com