Battery charger

A battery charger and circuit technology, applied in the direction of battery circuit devices, current collectors, instruments, etc., can solve the problems of not being able to adapt to a wide voltage range, versatility, safety, reliability and perfect protection not reaching single-chip microcomputers, poor versatility, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

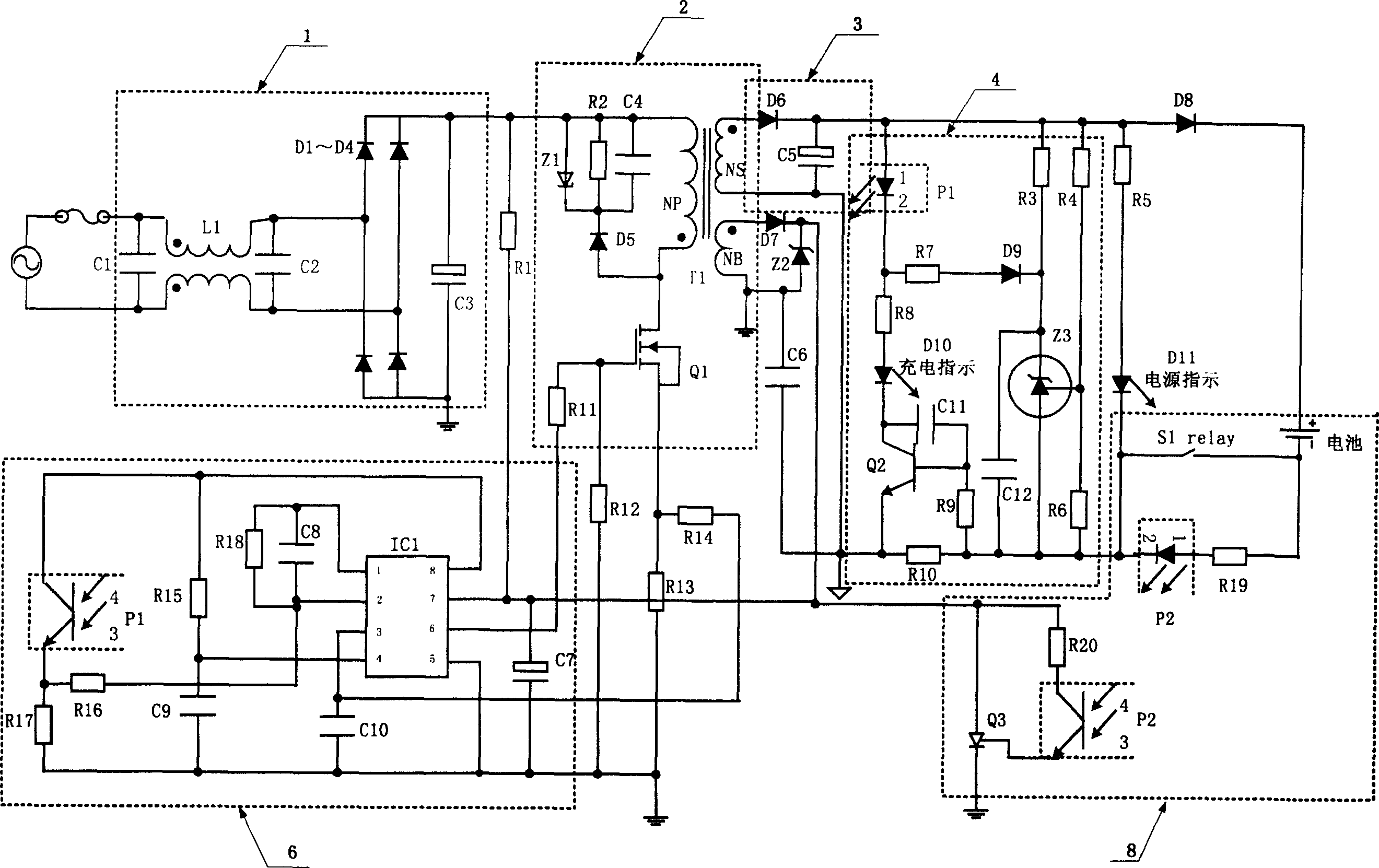

[0009] The embodiment will be described in further detail below according to the accompanying drawings.

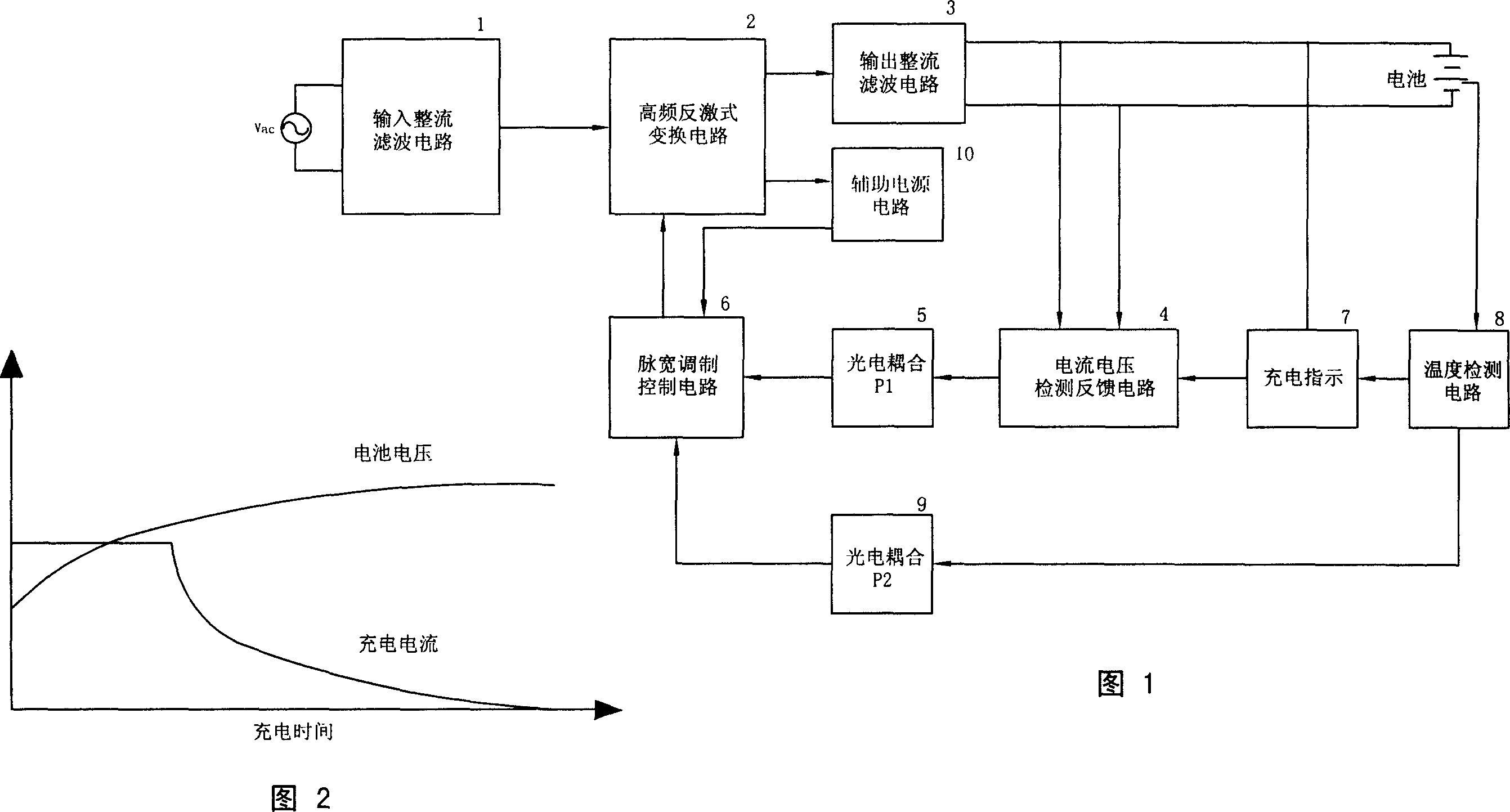

[0010] Figure 1 is a circuit block diagram, including input rectification and filtering circuit 1, high frequency flyback conversion circuit 2, output rectification and filtering circuit 3, current and voltage detection feedback circuit 4, photoelectric coupling P1 circuit 5, pulse width modulation control circuit 6, photoelectric coupling P2 circuit 9 and auxiliary power supply 10 . The photoelectric coupling circuit 5 inputs the given signal of the current and voltage detection feedback circuit 4 into the pulse width modulation control circuit 6 to feed back the output duty cycle. The temperature detection and protection circuit is composed of a battery temperature detection circuit 8, a photoelectric coupling circuit P2, and a pulse width modulation control circuit 6. The photoelectric coupling P2 is connected to the output terminal of the battery temperature detection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com