Lithium ion battery capacity detection and direct-current internal resistance detection method

A lithium-ion battery, capacity detection technology, applied in the direction of measuring electrical variables, measuring electricity, measuring devices, etc., can solve the problems of equipment cost, increase in later maintenance costs, inconvenient production management, and multiple grades, and save equipment investment costs. , The effect of saving later maintenance costs and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

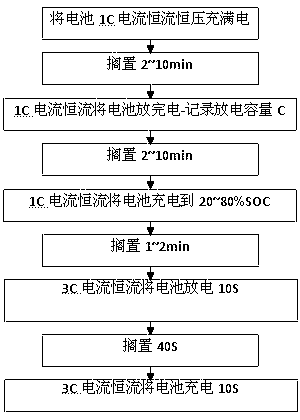

[0013] Step 1. Capacity detection: Place the battery to be tested on the capacity DCIR detector, fully charge it with 1C current and constant voltage, leave it for 2-10 minutes, and then use 1C current and constant current to discharge the battery, and record the discharge capacity as C , C is the actual power discharged by the battery capacity test;

[0014] Step 2. Battery charge SOC: After the capacity test is completed, put it aside for 2~10 minutes, and charge the battery with constant current according to the customer's request of 20~80% SOC. The charge is the shipped SOC charge;

[0015] Step 3, the battery DCIR DC internal resistance value detection: in the state of step 2, put it aside for 1~2 minutes, discharge the battery with 3C current constant current for 10 seconds, put it aside for 40 seconds, charge the battery with 3C voltage constant current for 10 seconds The capacity DCIR detector can take any points for calculation during discharging and charging, avoiding a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com