A kind of evaporation concentration method and equipment of cyclohexane oxidation waste lye

A technology for evaporating and concentrating waste lye, applied in chemical instruments and methods, evaporation, separation methods, etc., can solve the problems of easy condensation reaction, low recovery efficiency, product loss, etc., to avoid the precipitation of sodium carbonate and scaling, Effects of avoiding local overheating, accelerating heat transfer and mass transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

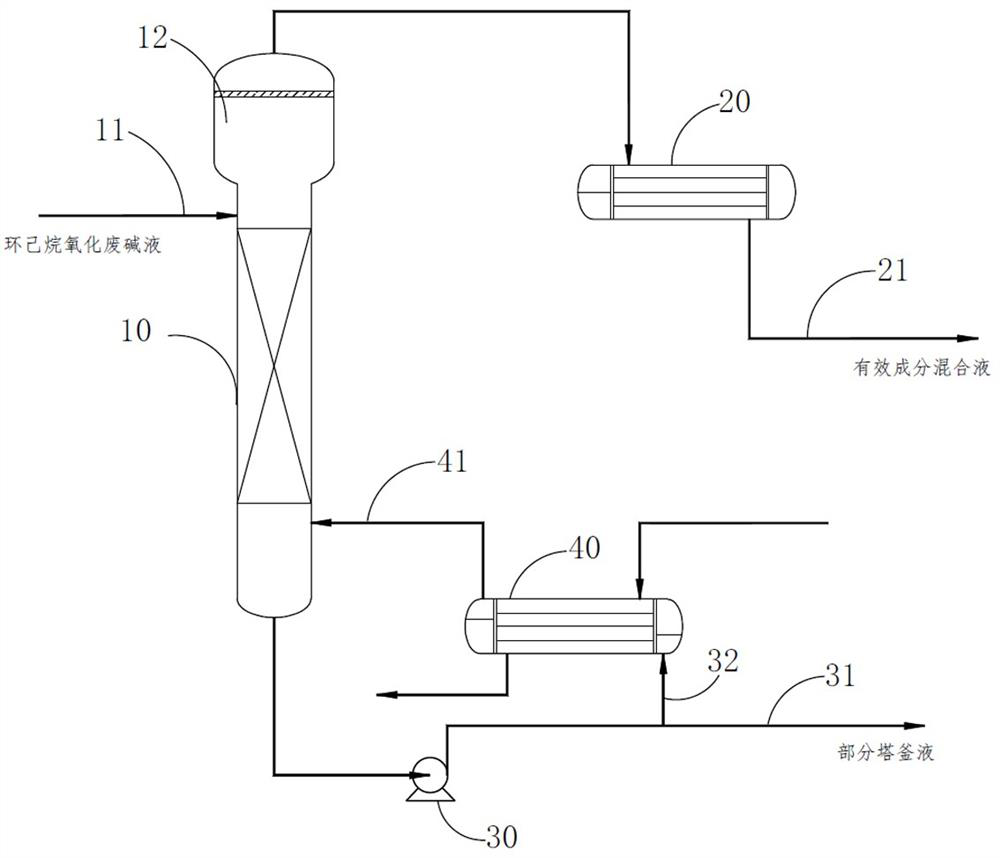

[0028] see figure 1 , the evaporation concentration equipment of the present embodiment comprises a waste caustic stripping tower 10, a gas phase condenser 20, a bottom liquid circulation pump 30 and a bottom liquid heater 40, and the top of the waste caustic stripping tower 10 is connected to Hexanaphthene oxidation spent lye pipeline 11, the top of described spent lye stripping tower 10 is connected with gas-phase condenser 20 by pipeline, and described gas-phase condenser 20 connects mixed condensate pipeline 21; Said spent lye The tower still of stripper 10 is communicated with tower still heater 40 by circulation line I 41, and described tower still heater 40 is also communicated with tower still by circulation line II 41, and the tower still of described waste lye stripping tower 20 A tower still liquid circulation pump 30 is connected between the tower still heater 40, and the tower still of the waste lye stripping tower 10 is connected with a discharge line 31 after t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap