Vision-based online measurement method for weld joint forming characteristics of thick plate T-shaped joint

A technology of welding seam forming and measuring method, which is applied in welding equipment, metal processing equipment, manufacturing tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

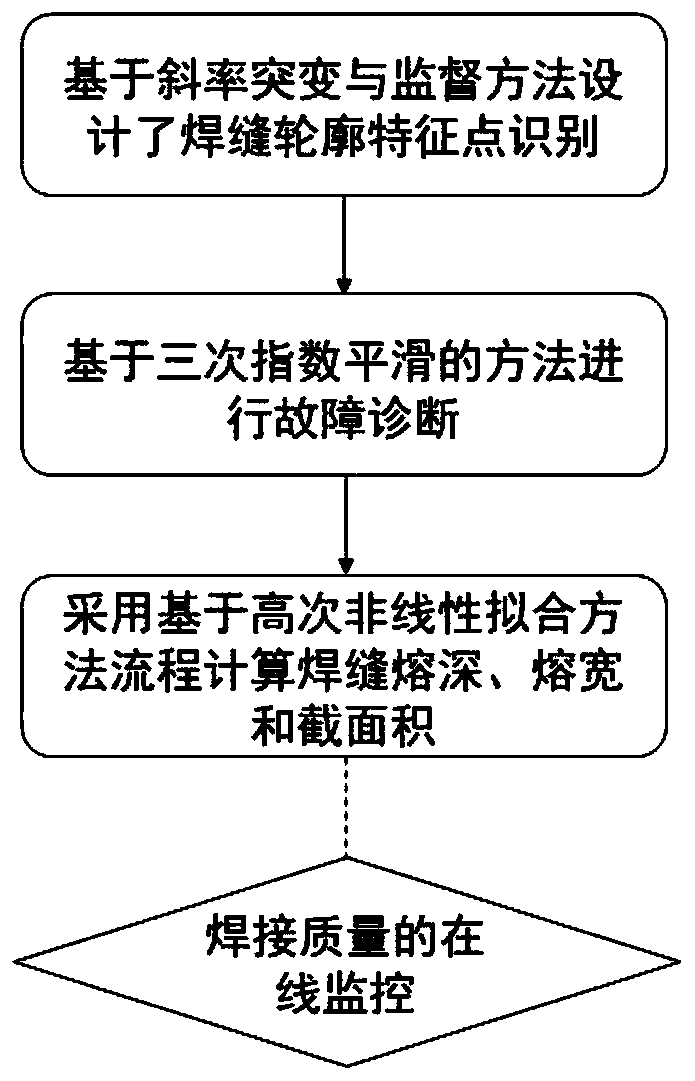

[0049] Embodiment 1: A vision-based online measurement method for weld seam formation characteristics of thick plate T-shaped joint welding, such as figure 1 shown, including the following steps:

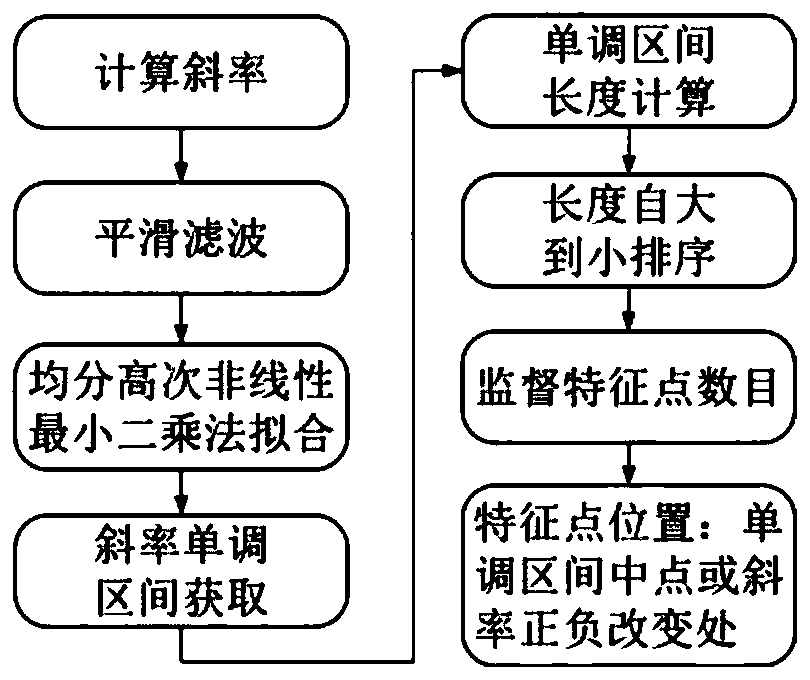

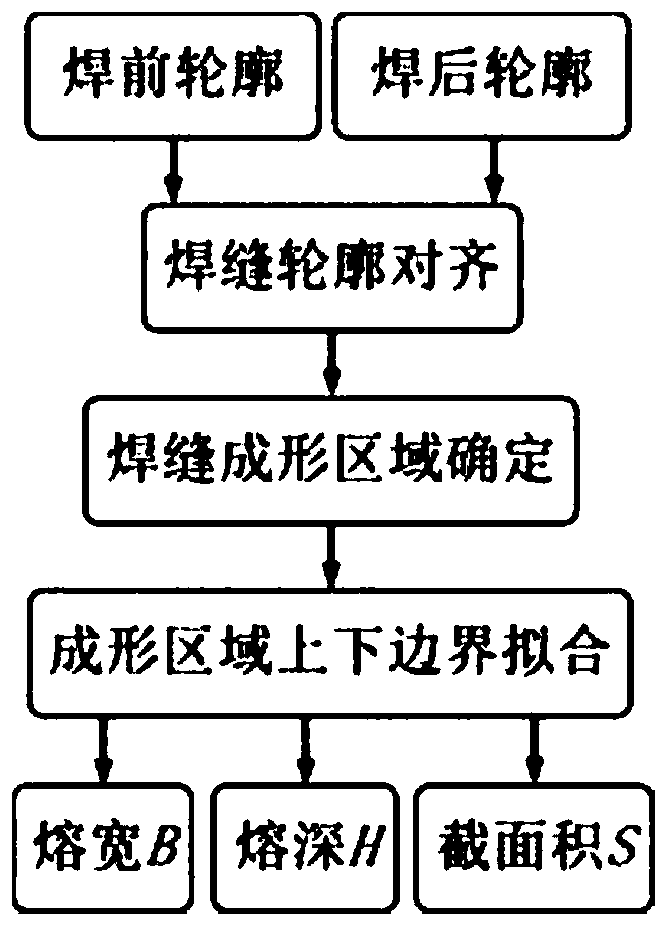

[0050] Step 1. Use the idea of average sliding to calculate the slope value of each data point of the extracted linear weld profile, and then use the equipartition high-order nonlinear least squares fitting method to suppress the influence of the local disturbance of the slope and effectively approximate the overall change characteristics of the slope , and the fitted data are subjected to mutation detection, and finally the feature points of the weld contour are obtained according to the supervision method.

[0051]Step 2. In view of the invalid weld contour feature recognition, according to the sampling data before the current sampling time, using the triple exponential smoothing algorithm, a fault detection method for weld contour feature point extraction is proposed to realize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com