Punching machine

A punching machine, strip technology, applied in the filtration of dispersed particles, transportation and packaging, separation of dispersed particles, etc., can solve the problems of unstable position, misalignment, health hazards of operators, etc., to ensure the operating environment, The effect of improving processing quality and ensuring physical health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

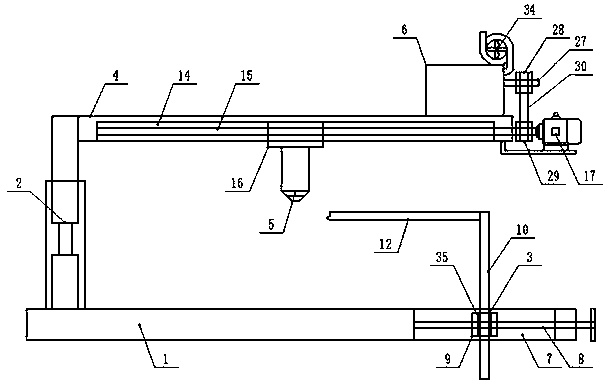

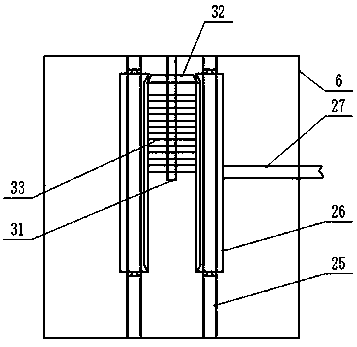

[0016] Embodiment 1: see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , a punching machine provided by the present invention is now described, including a base 1, an electric control telescopic support frame 2 is vertically fixed on the upper end of one side of the base 1 in the length direction, and a positioning adjustment mechanism 3 is provided on the other side , the top of the electronically controlled telescopic support frame 2 is fixed with a horizontal support frame 4, the lower end of the horizontal support frame 4 is provided with a punch 5, and the upper end is provided with a dust collection shell 6, and the positioning adjustment mechanism 3 includes a bar-shaped pass The first screw mandrel 8 provided on the middle side of the inner end of the mouth 7 and the strip-shaped opening 7 along the width direction of the inner end, the first screw mandrel 8 moves through the first sliding seat 9 provided, and the first sliding seat 9 outside The baffle p...

Embodiment 2

[0017] Example 2: see figure 1 Now, a punching machine provided by the present invention will be described. The electronically controlled telescopic support frame 2 includes a hollow main frame body vertically fixed on the upper end of the base 1, and a vertically movably inserted top end of the hollow main frame body. The movable secondary frame body and the telescopic cylinder provided between the insertion end of the movable secondary frame body and the bottom end wall of the hollow main frame body, the horizontal support frame 4 is fixed horizontally at the position corresponding to the positioning adjustment mechanism 3, and the horizontal The lower end of the support frame 4 is provided with a strip groove 14 along its length direction, and a fourth screw rod 15 and a strip slide seat 16 are arranged in the strip groove 14, and the fourth screw rod 15 moves through the The bar-shaped sliding seat 16 is designed, and a fourth screw drive assembly is provided between the i...

Embodiment 3

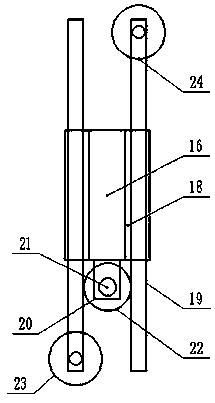

[0018] Embodiment 3: see figure 1 , figure 2, a kind of punching machine provided by the present invention is described now, and the outer end walls of the two sides of the strip-shaped sliding seat 16 along the length direction of the base 1 are respectively provided with strip-shaped slide grooves 18, and the strip-shaped slides Slots 18 are all opened along the width direction of the base 1 and are designed with openings at both ends of the length direction. Bar slide bars 19 are respectively provided in the strip slide grooves 18, and the strip slide seats 16 are arranged along the The outer end wall on one side of the width direction of the base 1 is provided with a rotating shaft installation frame 20, and the upper end of the rotating shaft mounting frame 20 is vertically provided with a rotating shaft 21, and the outer part of the rotating shaft 21 and corresponding to the position of the strip slide bar 19 are covered with a second A gear 22, the first tooth grooves...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com