Low-yield-ratio and high-strength steel plate having 690-MPa-level yield strength and manufacturing method thereof

A technology of yield strength and low yield strength ratio, applied in the field of low yield strength ratio and high strength steel plate manufacturing, can solve the problems of performance uniformity and cutting deformation, large residual stress, high alloy cost, and avoid the yield strength ratio. The effect of rising, ensuring the uniformity of the whole plate, and reducing the cost of alloying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

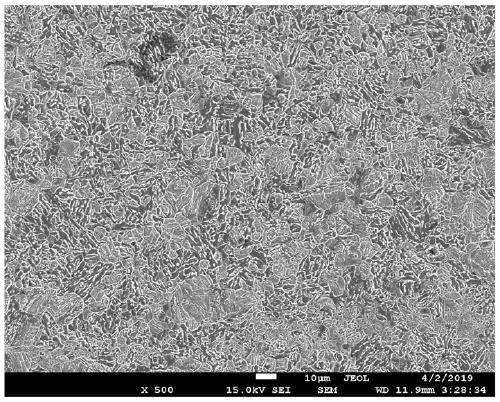

Image

Examples

Embodiment Construction

[0035]The present invention will be further described in detail below in conjunction with the examples. The examples are exemplary and intended to explain the present invention, but should not be construed as limiting the present invention.

[0036] The production process of the low yield ratio 690MPa steel plate of the present invention: converter or electric furnace steelmaking -> LF refining -> VD or RH vacuum degassing -> Ca treatment -> continuous casting -> heating -> rolling -> once Quenching -> secondary quenching -> tempering.

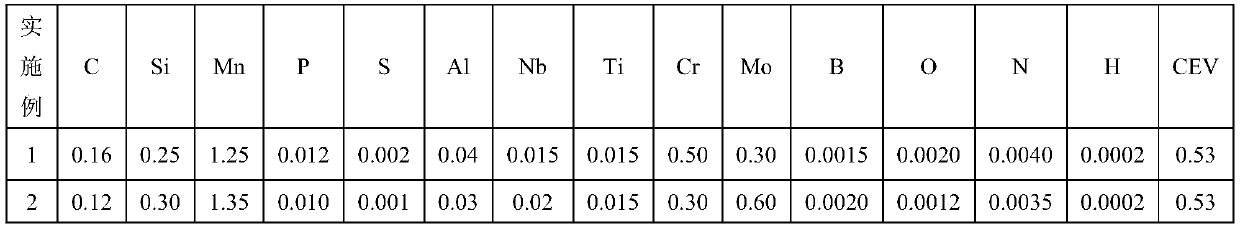

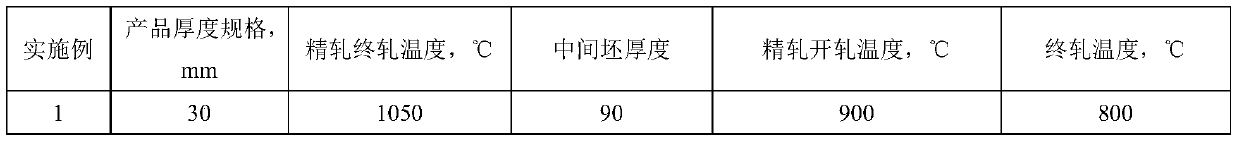

[0037] The manufacturing method of the yield strength 690MPa level low-yield ratio high-strength steel plate of the embodiment of the present invention 1-2 all adopts the following steps:

[0038] (1) Steelmaking and continuous casting: Smelting in a 150-ton converter, and then sent to an LF furnace for refining and RH vacuum degassing treatment, and Ca treatment after breaking the air. The molten steel is cast into a continuous casting slab ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com