Pressing panel

A panel and button technology, which is used in construction, water supply installations, washing equipment with water tanks, etc., can solve the problems of poor pressing feel and increased pressing force, and achieves low pressing force, small change in pressing force, and small amount of elastic deformation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

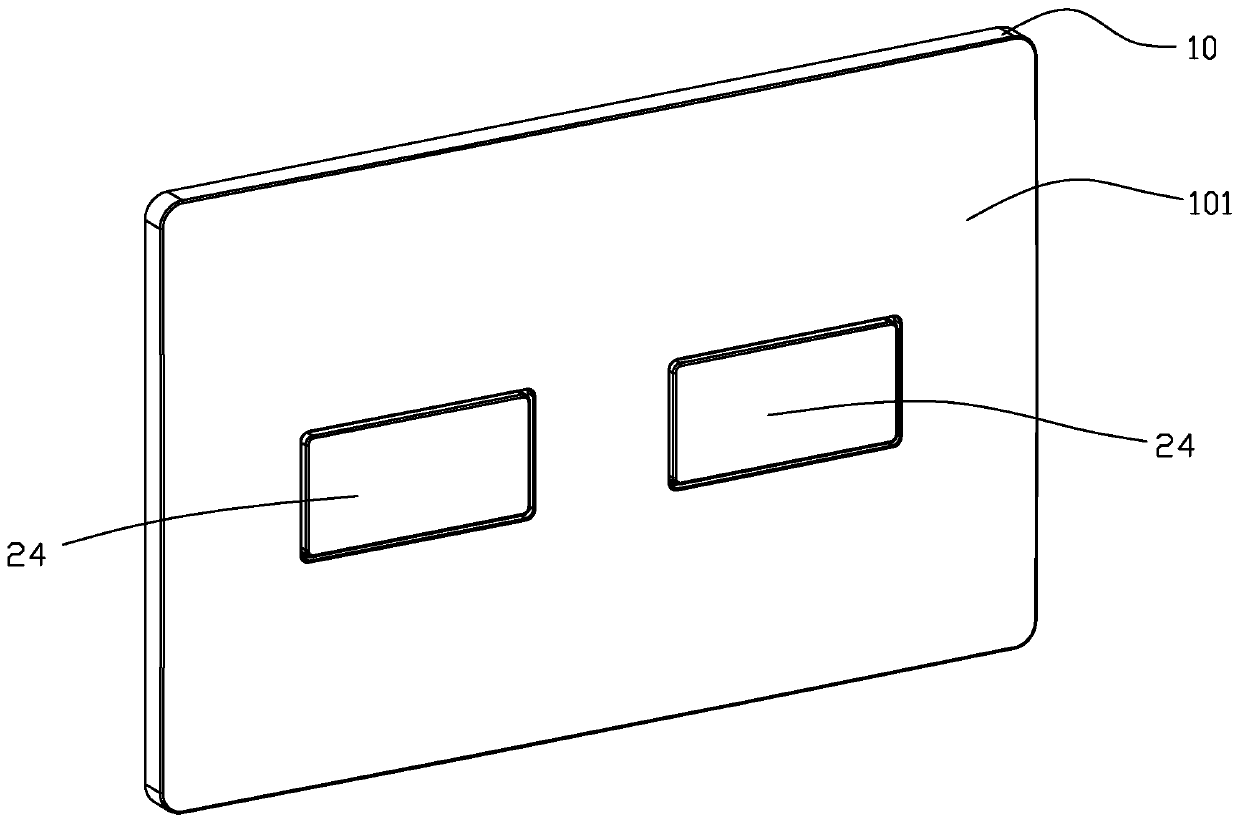

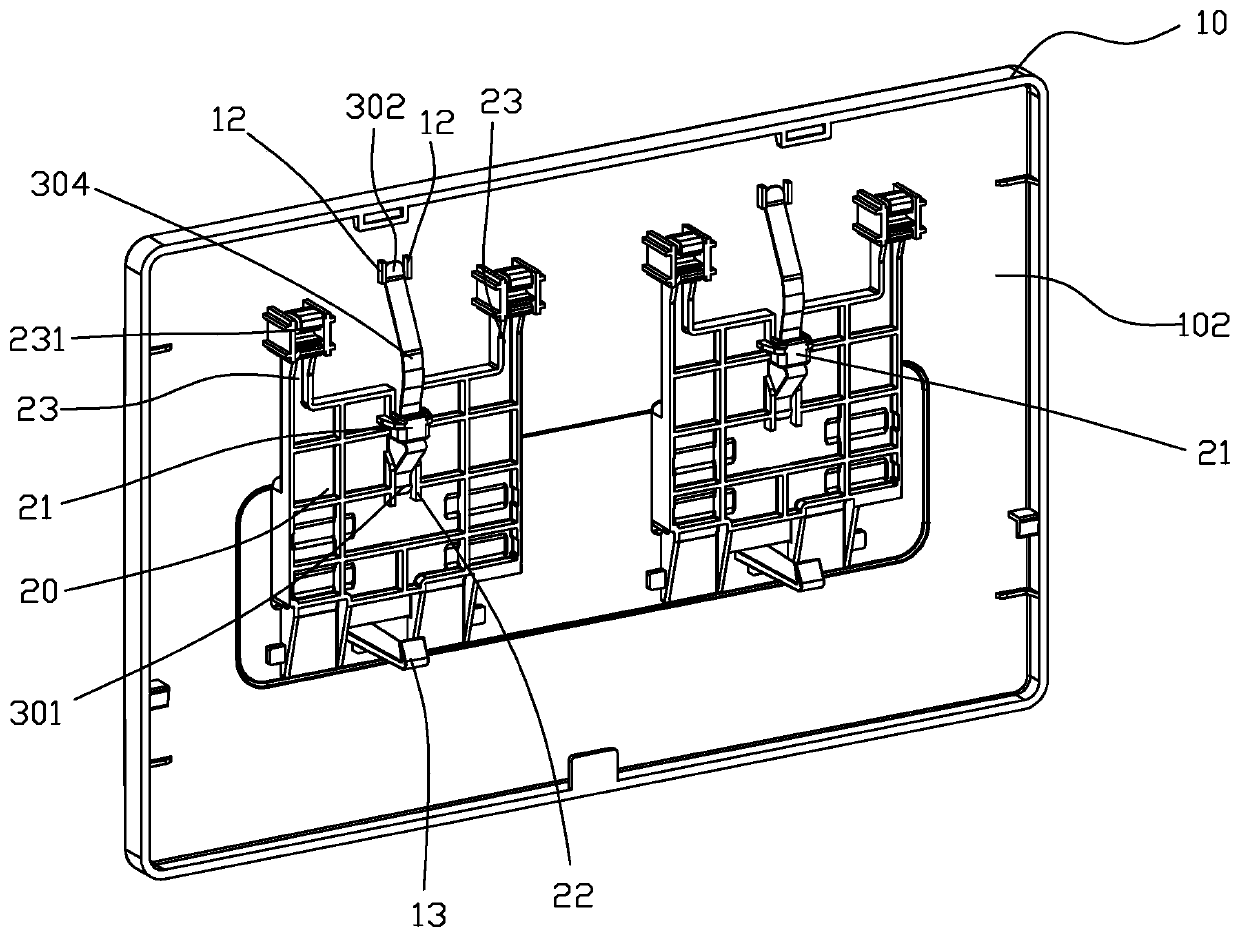

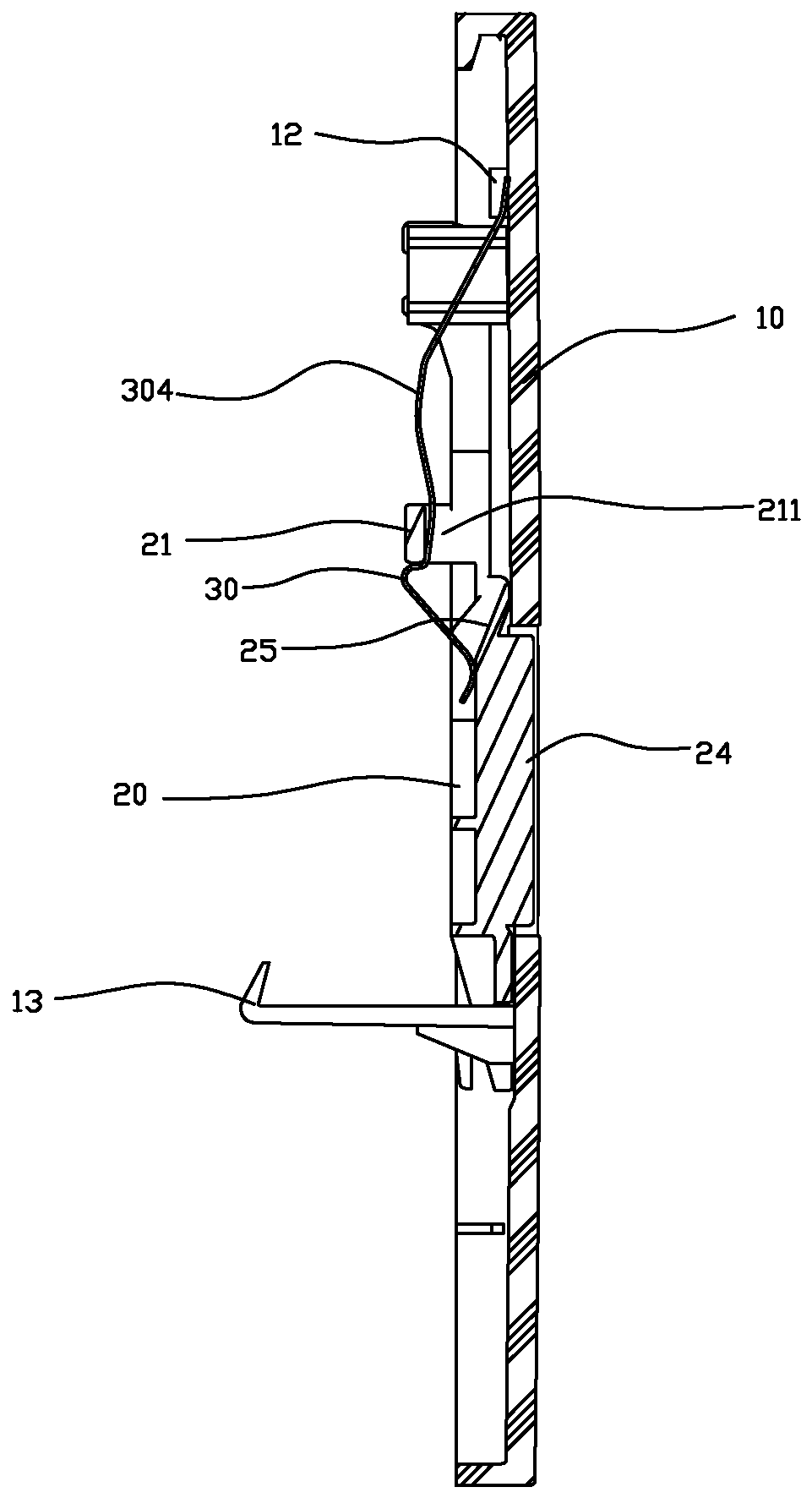

[0034] refer to Figure 1 to Figure 7 As shown, a pressing panel provided in this embodiment includes a panel 10, a button 20 and an elastic member 30. The button 20 is hinged on the panel 10, so that it can move relative to the panel 10 with the hinge shaft 231, so the button 20 is hinged on the panel 10. The elastic member 30 is fixed on the button 20, and the elastic member 30 has an elastic support arm 304 extending outward. The elastic support arm 304 presses the panel 10 through its elastic force, and the button 20 is opposite to the panel 10. During the movement of the hinge shaft, the elastic support arm 304 will slide at the pressing position of the panel 10, and in the initial state where the button 20 is not pressed, as shown in the following figure: figure 2 and image 3 As shown, the pressing position of the elastic support arm 304 on the panel 10 (ie, the second end 302 described below) is farther from the fixed position of the button 20 and the elastic member ...

Embodiment 2

[0046] A pressing panel provided in this embodiment has substantially the same structure as that of the first embodiment, except that: refer to Figure 9 As shown, in this embodiment, the elastic member 30 is a long elastic linear body, such as an elastic metal wire. The structure and installation structure of the elongated elastic linear body are the same as those of the elastic sheet in the first embodiment, and the description will not be repeated here.

Embodiment 3

[0048] The pressing panel provided in this embodiment has substantially the same structure as Embodiments 1 and 2, and has the same assembly structure of the panel and the button. The elastic member in this embodiment only has the part of the elastic support arm in the above-mentioned first and second embodiments. The elastic member is fixed on the button by means of bolts or riveting, and the part of the elastic support arm extends outward in the shape of a The structures of the first and second embodiments above.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com