Tunnel drainage structure combining deeply-buried central ditch and drainage tunnel and construction method

A technology for central ditch and tunnel drainage, which is used in drainage, earthwork drilling, safety devices, etc., can solve problems such as the inability to discharge and freeze groundwater in time, the ditch in the cave, the ice on the track bed, and the impact on operational safety, etc. And the effect of good cold protection, simple building layout, clear and simple principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in detail below in combination with specific embodiments.

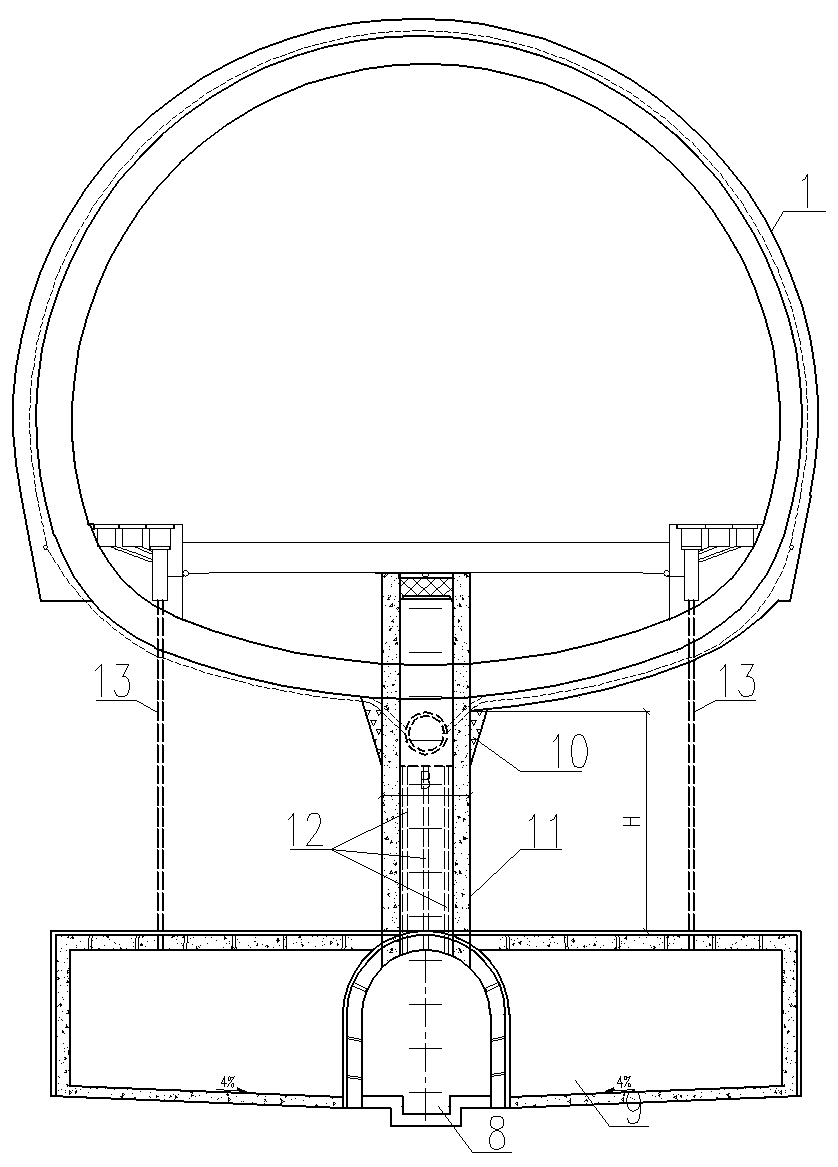

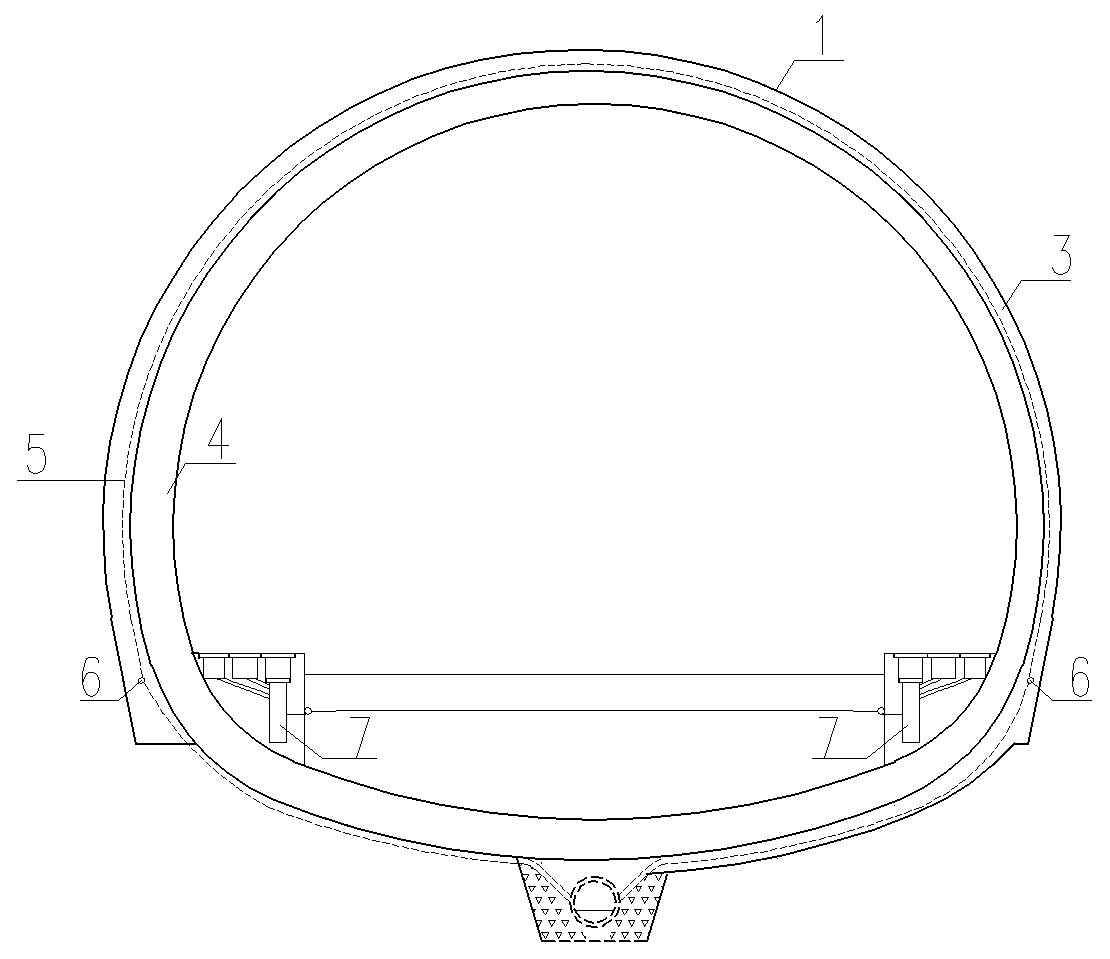

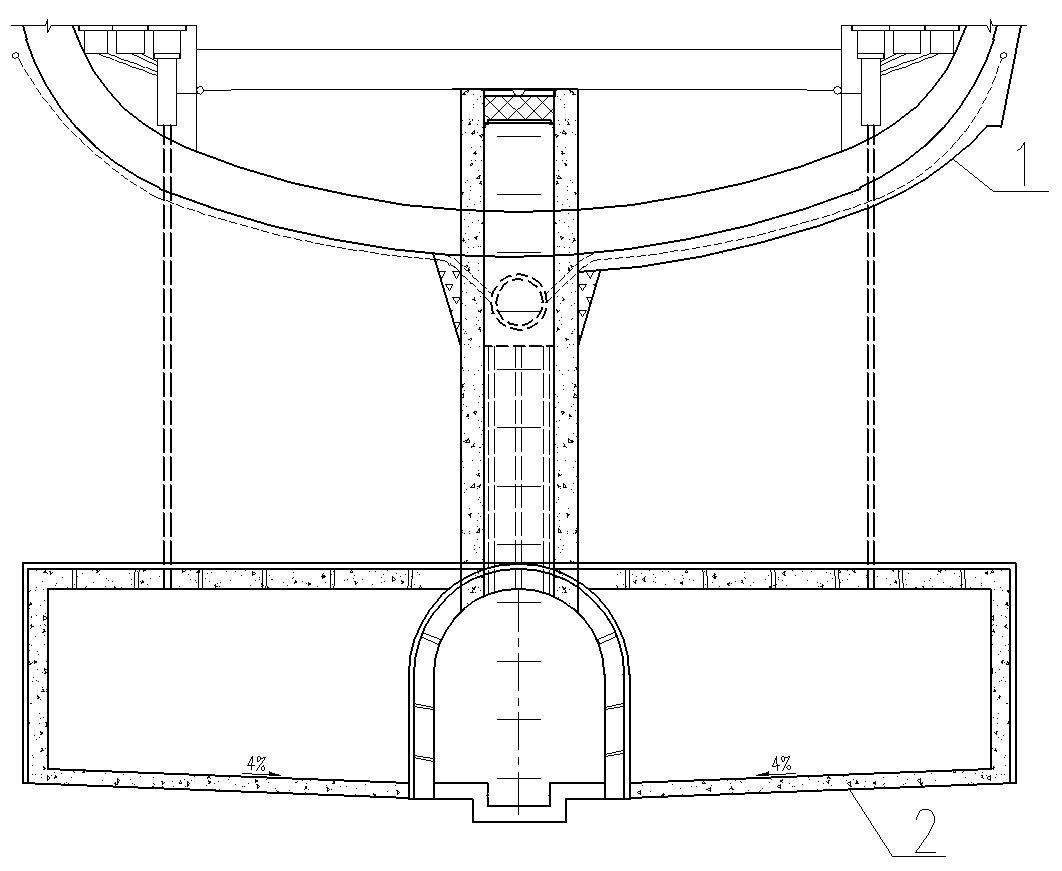

[0042] The invention relates to a tunnel drainage structure combined with a deep-buried central ditch and a drainage tunnel, aiming at water-proof and cold-proof settings for tunnel engineering in plateau and high-cold regions, so as to ensure the structural safety of the tunnel during the service period without freezing damage. The structure includes an upper drainage cold-proof structure 1 and a lower drainage cold-proof structure 2; the upper drainage cold-proof structure 1 includes a circular blind pipe 5 located between the tunnel primary support 3 and the second tunnel lining 4; the lower drainage cold-proof structure 2 includes a deep buried center The ditch 10 and the longitudinal drain hole 8; the deep buried central ditch 10 is longitudinally arranged below the centerline of the tunnel invert, and the longitudinal drain hole 8 is longitudinally arranged below the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com