Spiral buckle type screw-free pressure reducing valve

A pressure reducing valve and screwless technology, which is applied in the field of pressure reducing valves, can solve the problems of low production efficiency and achieve the effect of simple structure, good cost performance and reduced parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

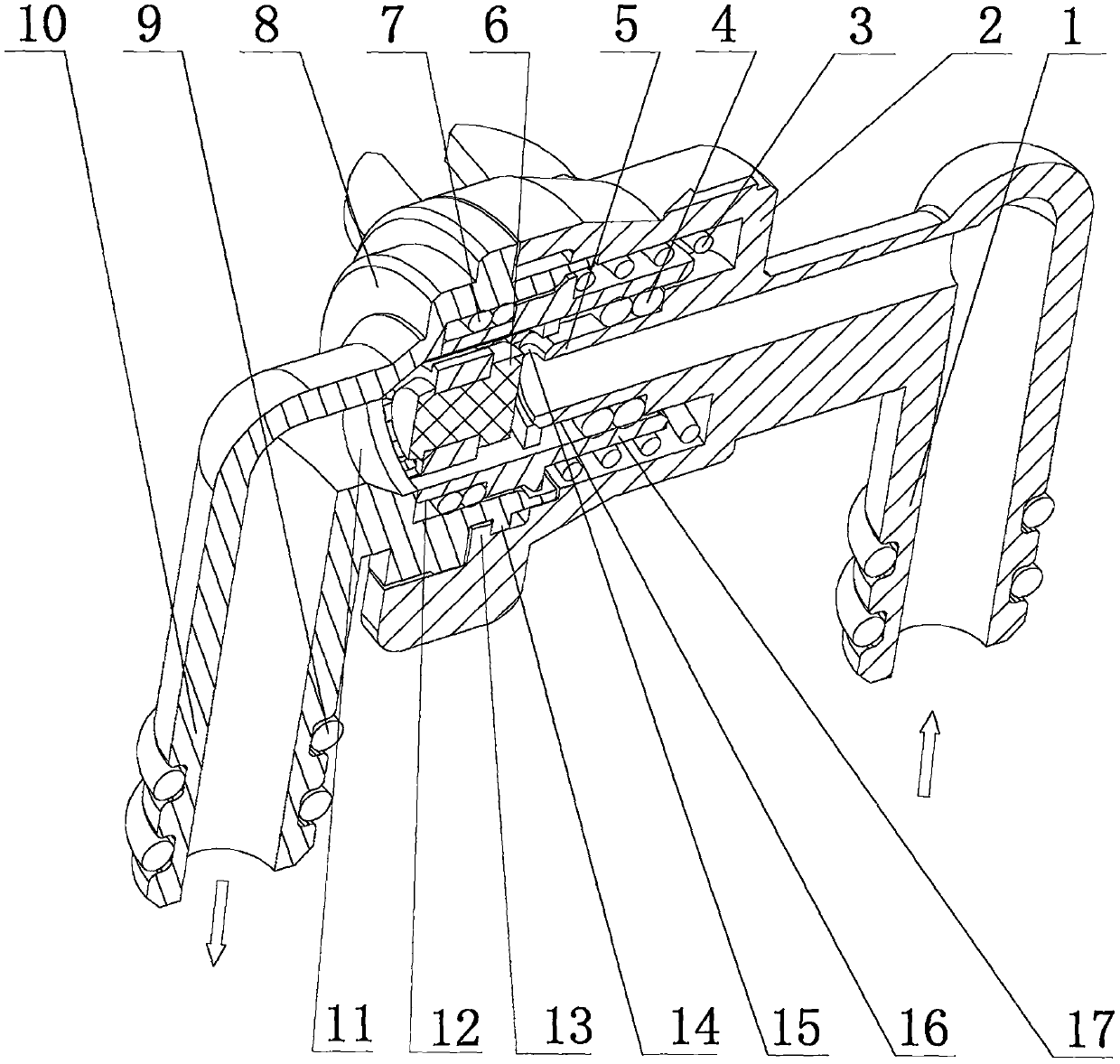

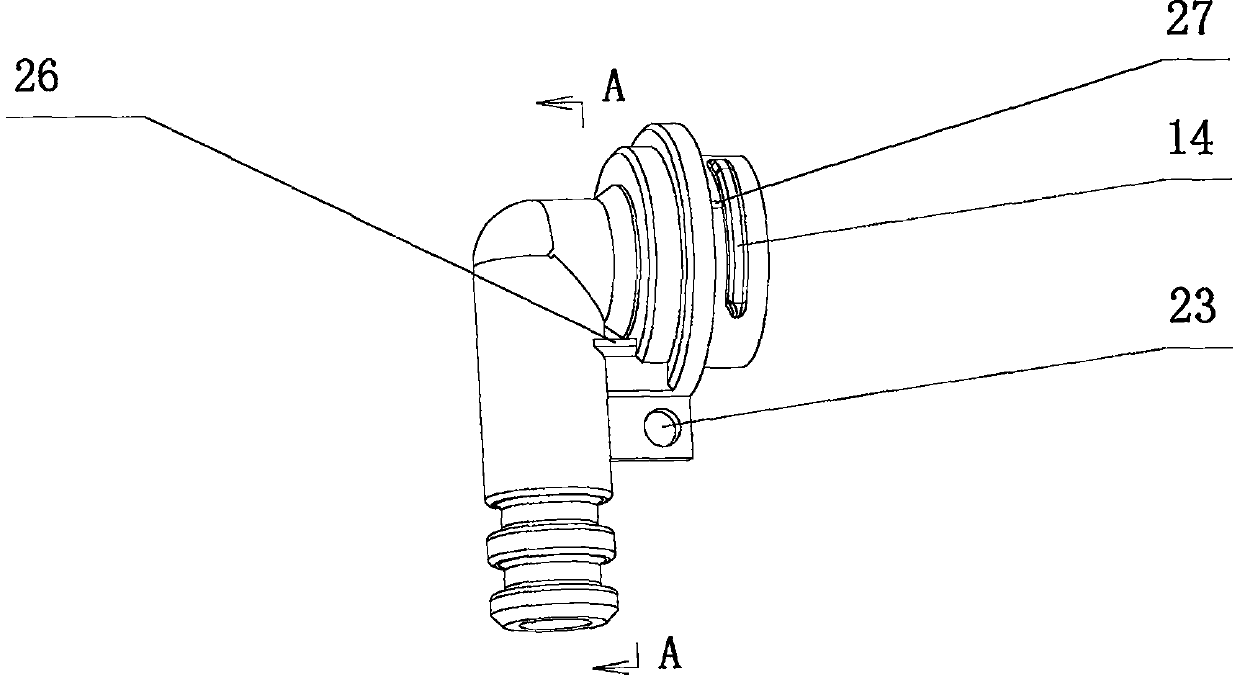

[0029] Specific implementation mode one: see Figure 1 to Figure 12 , a pressure reducing valve with a screw buckle without screws, mainly including a front cover 2, a valve core 5, a valve core "O" ring 4, a rubber plug 6, a piston 17, a piston "O" ring 7, a spring 3, The rear cover 8 is characterized in that the front cover 2 and the rear cover 8 are connected by screw snaps, and the design scheme does not need to be assembled with screws 53; the piston "O" ring 7 inside the pressure reducing valve is set on the outer cylindrical surface 12 of the piston, It forms a sealing fit with the back cover 8, and the valve core "O" ring 4 is sleeved on the outer cylindrical surface 16 of the valve core, and forms a sealing fit with the inner cylindrical surface of the water inlet end of the piston 17. The rubber plug 6 is installed on the piston 17, and the piston 17 is reciprocated between the front cover 2 and the rear cover 8 by compressing the spring 3. The water inlet and outle...

specific Embodiment approach 2

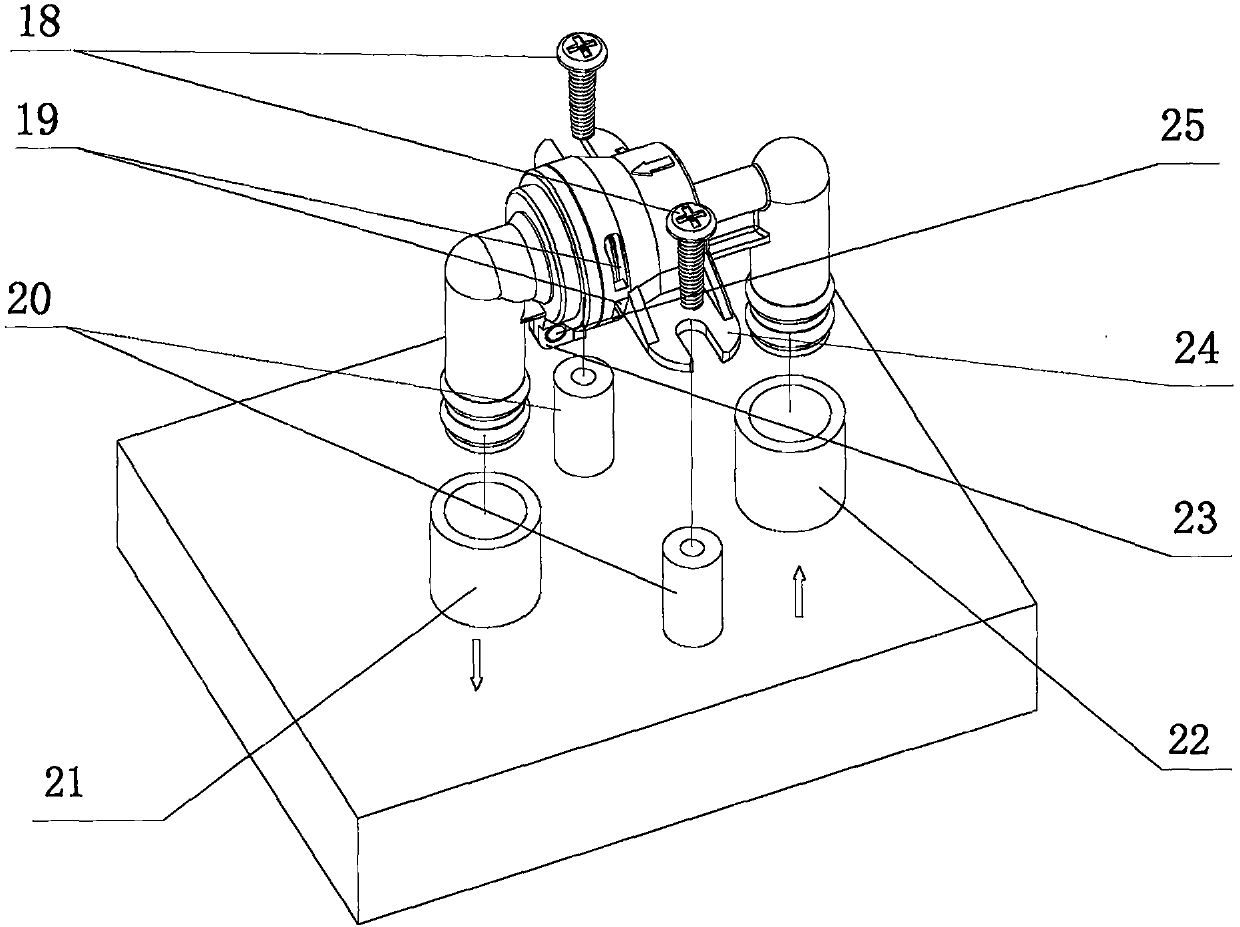

[0037] The second specific embodiment, this embodiment is a specific application example of the present invention, that is, the application on a common, non-U-shaped pressure reducing valve. see Figures 1 to 7 , see Figure 8 to Figure 9, a screwless screwless pressure reducing valve, mainly including a front cover 43, a valve core 42, a valve core "O" ring 41, a rubber plug 36, a piston 39, a piston "O" ring 37, a spring 40, The rear cover 35 is characterized in that the front cover 43 and the rear cover 35 are connected by a screw buckle, and no screw 55 is used for assembly; the piston "O" ring 37 inside the pressure reducing valve is sleeved on the outer cylindrical surface of the piston 39, It forms a sealing fit with the back cover 35, and the spool "O" ring 41 is sleeved on the spool 42, and forms a sealing fit with the inner cylindrical surface of the water inlet end of the piston 39. The rubber plug 36 is installed on the piston 39, and the piston 39 is between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com