Fabrication method of polymer fiber Bragg grating strain sensor and smart cable

A strain sensor and fiber grating technology, applied in the directions of cladding fiber, optical waveguide light guide, instruments, etc., can solve the problems of inconvenient installation, low sensitivity, and inaccurate measurement of steel cables, and achieve fast installation speed and high sensitivity. , the effect of increasing the signal transmission distance

Active Publication Date: 2022-05-31

GUANGXI UNIV +1

View PDF23 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] In the prior art, strain sensors are needed to measure the strain force of chilled cast anchor cables in use, but ordinary strain sensors are not sensitive enough, reliable enough, not accurate enough to measure, and not easy to install with steel cables. Therefore, the present invention proposes the manufacturing method of polymer fiber Bragg grating strain sensor, intelligent cable to solve the problems existing in the prior art

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0039] The foregoing has shown and described the basic principles, main features and advantages of the present invention. Technicians in the industry should

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Login to View More

Abstract

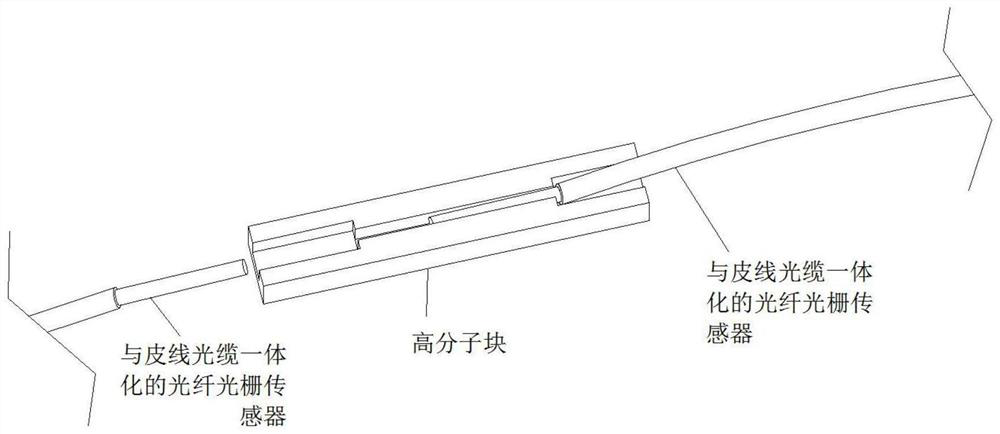

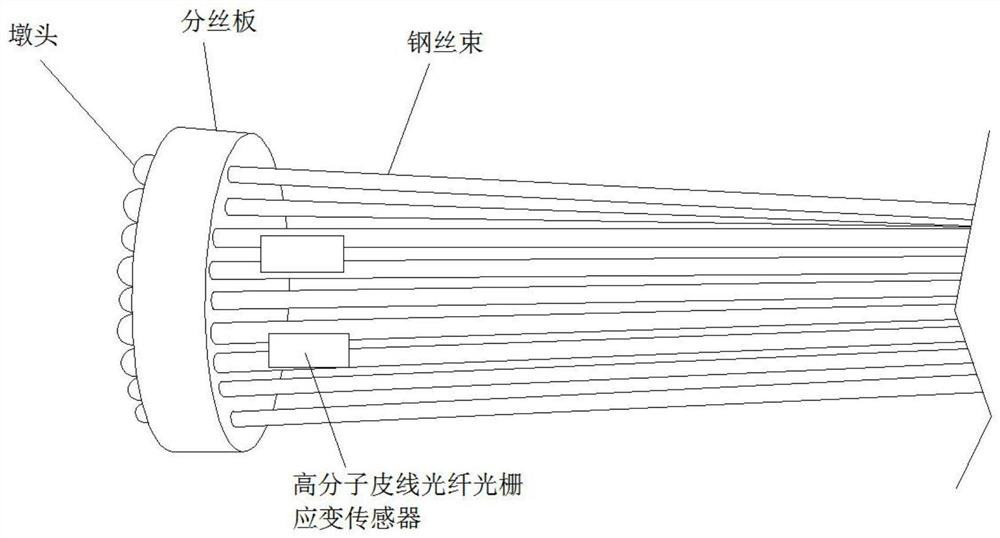

The invention discloses a manufacturing method of a polymer leather fiber grating strain sensor and an intelligent cable. Pull cable and make finished cable; The present invention utilizes the optical fiber grating sensor of leather wire optical cable to obtain integrated with the fiber Bragg grating sensor of leather wire optical cable through photolithography process, sticks with polymer block to form polymer fiber Bragg grating strain sensor of leather wire, and its reflection wavelength and strain have Linear relationship, it has photosensitive characteristics, high sensitivity, strong anti-electromagnetic interference, and long life. It is matched with cable viscose, and the installation speed is fast, realizing dynamic and static strain monitoring. At the same time, connecting two sections of fiber grating through a polymer block can be Improve reliability, reduce optical signal loss, increase signal transmission distance and ensure clear and accurate fiber grating measurement signals. In engineering applications, it can be quickly installed and connected, which is more convenient.

Description

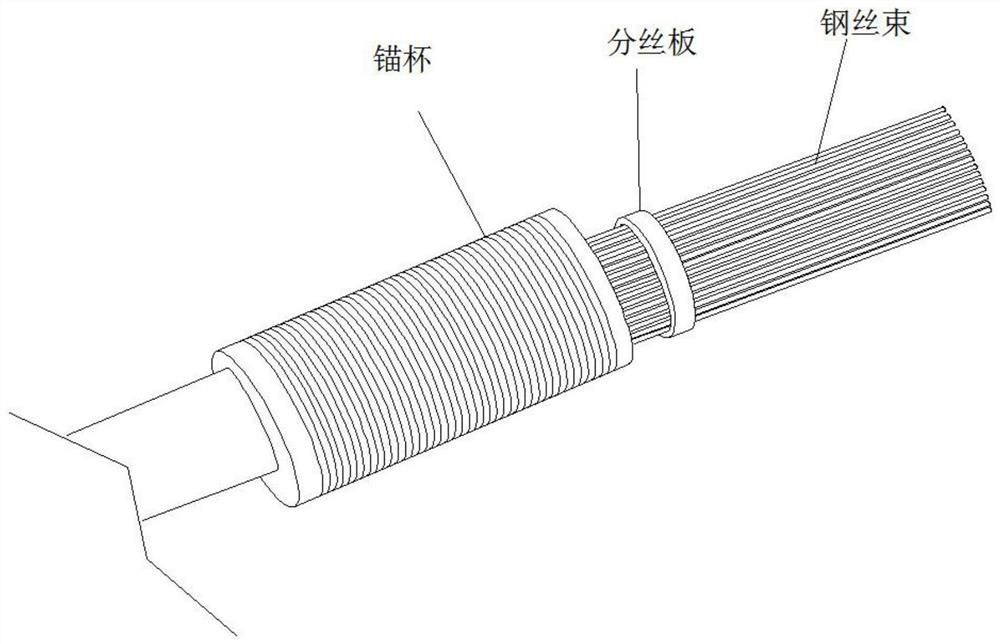

Fabrication method of polymer skin fiber grating strain sensor and smart cable technical field The present invention relates to the technical field of cold-cast anchor cables, in particular to polymer skin wire fiber grating strain sensors, intelligent How to make it. Background technique [0002] Cold cast anchor cables are widely used in bridge construction, especially in cable-stayed bridges, hanger arch bridges and suspension bridges. Application, the cable body currently used by the cold cast anchor is generally composed of 19471 high-strength steel wires with a diameter of C5 or 07mm. Grid finished cable body, also known as parallel wire cable in the industry, the parallel wire cable and cold cast anchors form a complete set of parallel steel Wire cold cast anchor cable is used as the stress component of bridge; [0003] In the prior art, the strain force of the chilled anchor cable in use needs to be measured with a strain sensor, and the general The sensitivi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G01B11/16G02B6/02E01D19/16

CPCG01B11/165G02B6/02123E01D19/16

Inventor 邓年春程华强肖铭钊梁冠亭郭晓

Owner GUANGXI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com