A multifunctional cooling device for optical fiber fusion splicer

A cooling device and optical fiber technology, applied in optics, light guides, optical components, etc., can solve the problems of harsh operating environment, low visibility, low work efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] A further detailed description will be made below in conjunction with the accompanying drawings and embodiments of the present invention:

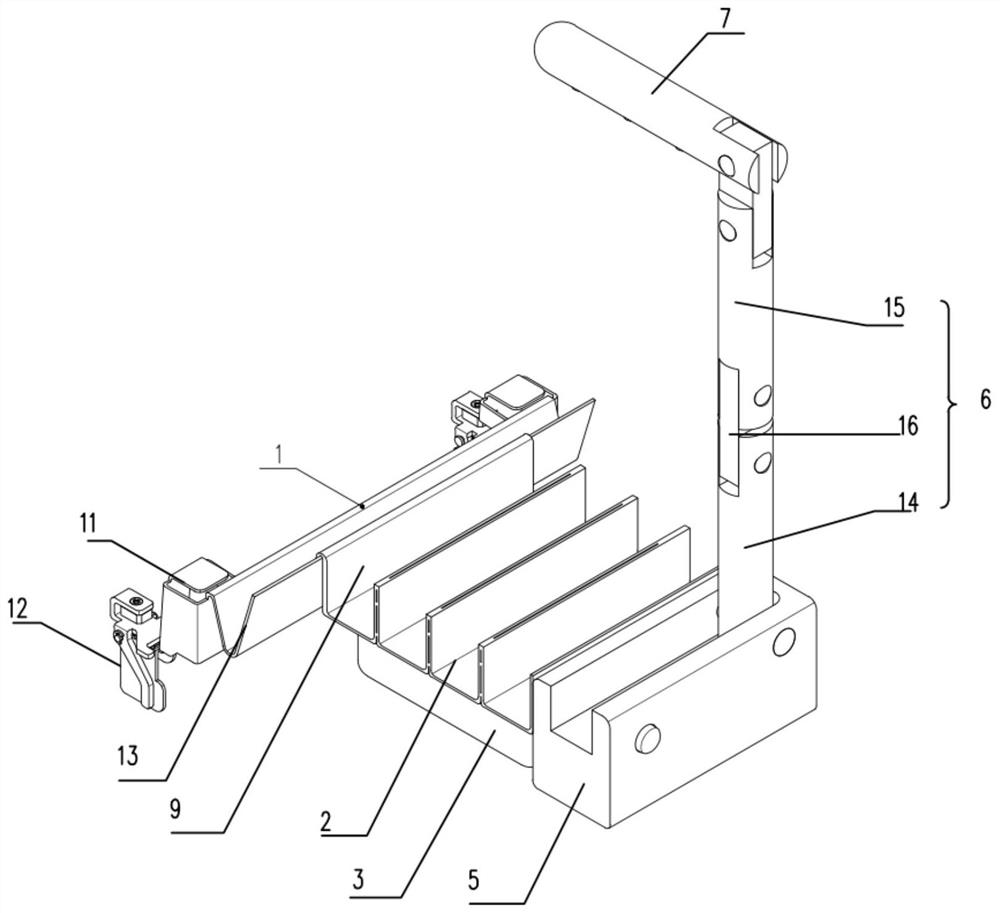

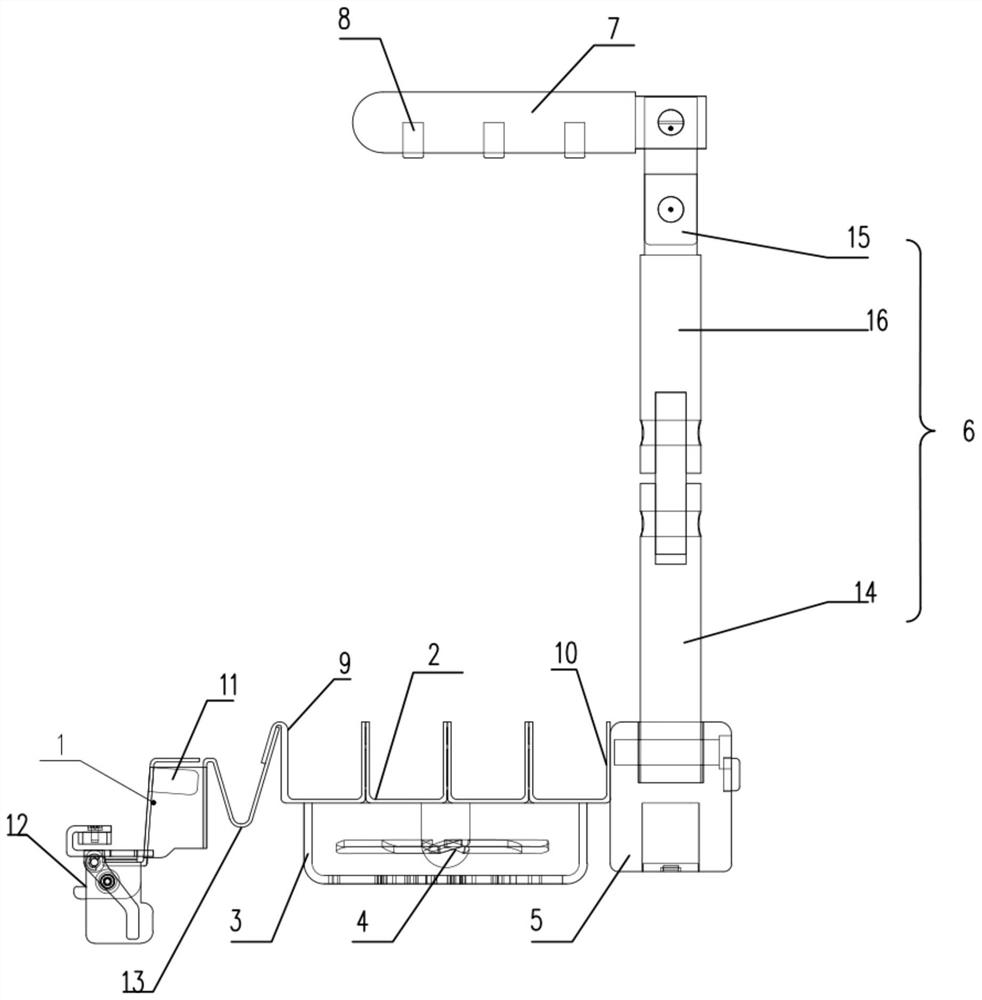

[0016] Such as Figure 1-2 As shown, a multifunctional cooling device for an optical fiber fusion splicer includes a fixed frame 1 fixed on the fiber fusion machine, a cooling plate and an illuminating device. Composed of a fan cover 4 for protecting the cooling fan 3, the lighting device includes a power supply box 5, a straightening rod 6 and a light stand 7, the top of the power supply box 5 is provided with a groove, and the bottom of the straightening rod 6 is connected to the The two side walls of the groove are connected by rotating shafts, the lamp frame 7 is arranged on the top of the straightening rod 6, and the lamp 8 is installed on the lamp frame 7, and the two sides of the expansion plate are respectively provided with a side plate A9 and a side plate B10, and the side plate B10 is fixedly connected with the power sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com