Aluminum-nickel composite lug welding station and welding method

A pole-ear welding and pole-ear technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of high rejection rate, high processing cost, low production efficiency, etc. Processing cost and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] The cathode material of some batteries, especially lithium-ion batteries, usually consists of pure aluminum. When the battery is assembled and used, it is necessary to connect the positive and negative electrodes of the battery to other electronic components by welding. However, the positive tab made of pure aluminum cannot be soldered directly. For this reason, a section of nickel strip is welded at the lead-out end of the positive pole lug of the battery, and then soldered with other electronic components through the nickel strip. Such a process is called positive tab aluminum to nickel process.

[0083] The basic method of the positive tab aluminum-to-nickel process is that the tab manufacturer welds the nickel strip to the positive tab with a laser welding machine to produce a single or disc-shaped aluminum-to-nickel tab strip. The specific steps are as follows:

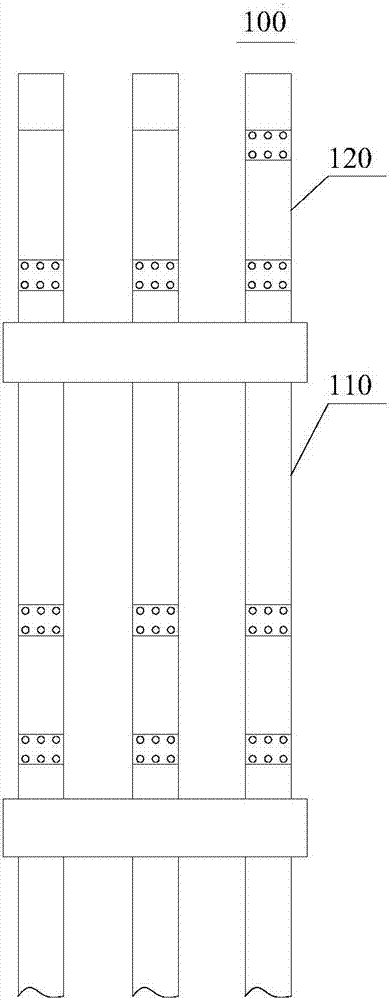

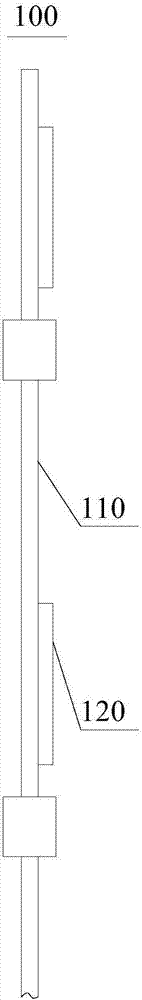

[0084] Such as figure 1 and figure 2 As shown, the strip-shaped nickel strip is cut into nickel s...

Embodiment 2

[0105] This embodiment provides a method for welding aluminum-nickel composite tabs. This method is based on the aluminum-nickel composite tab welding station described in Example 1. The method includes the following steps:

[0106] S1: the tab belt conveying device 360 transports the tab tab backward so that the front end face of the tab tab is located at the second welding position;

[0107] S2: The row-type aluminum tab transport device 350 moves to the aluminum tab cutting device 320, the aluminum tab cutting device 320 cuts the aluminum tab to obtain a row-type aluminum tab, and the row-type aluminum tab transfer device 350 undertakes the row-type The aluminum tab is moved to the first welding position and the rear end face of the row-type aluminum tab is located at the first welding position;

[0108] S3: The nickel strip cutting device 340 cuts the nickel strip to obtain nickel sheets. The nickel sheet transfer and delivery system picks up the nickel sheets and transp...

Embodiment 3

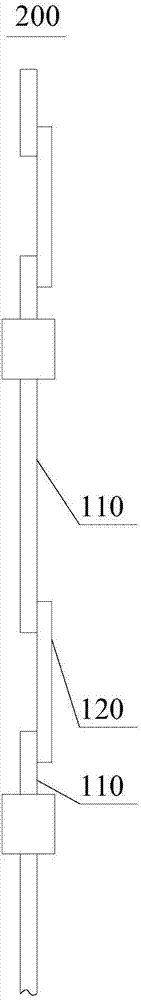

[0112] This embodiment also provides an Al-Ni composite tab welding station. The Al-Ni composite tab welding station provided in this embodiment is basically the same as the Al-Ni composite tab welding station 300 provided in Embodiment 1. The difference is that there is no row-type aluminum tab transport device, and the aluminum tab is directly transported backwards, so that the rear end of the aluminum tab is at the first welding position, and the two ends of the nickel sheet are welded to the aluminum tab. After the rear end and the front end of the tab strip, cut off the aluminum tab.

[0113] The specific structure is as follows:

[0114] A nickel strip processing system 311 and a welding positioning system 312 are arranged side by side on the rack 310 .

[0115] The nickel strip processing system 311 includes a nickel strip cutting device 340 and a nickel sheet conveying device 330 from front to back; the nickel strip cutting device 340 is used to cut the nickel strip ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com