A device and method for detecting abnormal welding of electrostatic discharge protection chips

A technology for electrostatic discharge protection and chip welding, which is applied to measuring devices, measuring electricity, measuring electrical variables, etc., which can solve the problems of difficult front and back marks of ESD protection chips, abnormal signals on LCD panels, and poor product assembly, saving manpower. Material cost, reduce the loss of defective rate, high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Preferred embodiments of the present invention will be described below with reference to the accompanying drawings.

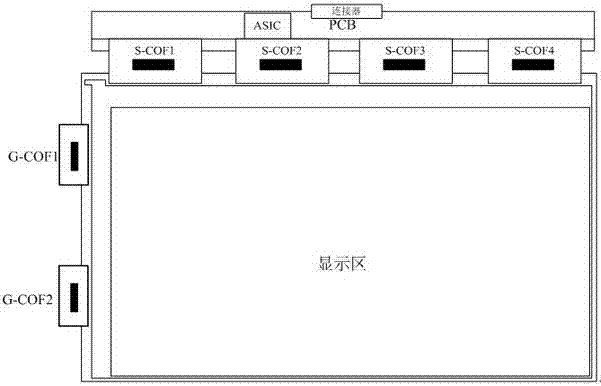

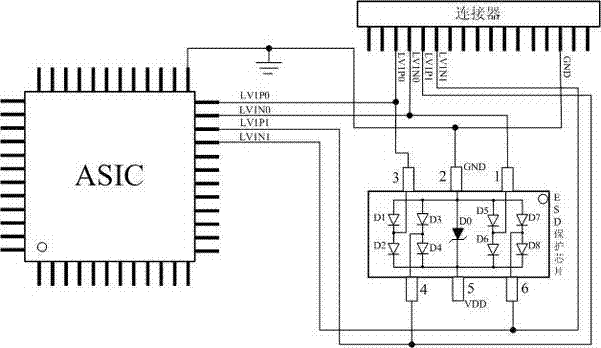

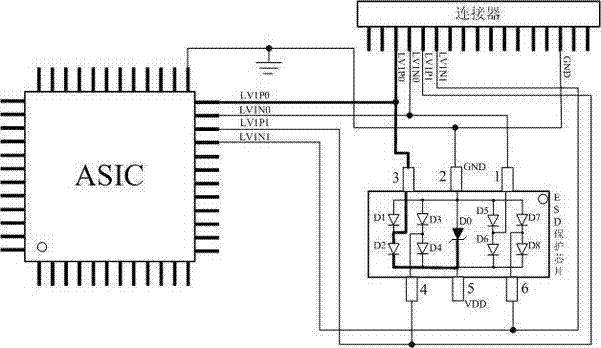

[0043] Such as Figure 5 As shown, it is a structural schematic diagram of an embodiment of the device for detecting abnormal bonding of ESD protection chips according to the present invention. From Figure 5 It can be seen from the figure that the device for detecting abnormal welding of electrostatic discharge protection chips includes:

[0044] The connector is used for plug-in connection with the signal input connector of the ASIC in the TFT-LCD;

[0045] The detection circuit is arranged on the connector, and is used for detecting whether the ESD protection chip is correctly welded on the ASIC, and prompting when the ESD protection chip is abnormally welded.

[0046] Wherein, a ground connection terminal (GND) and at least one LVDS connection terminal are provided inside the connector, and one end of the ground connection terminal is used to conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com